Update,

Bit of engine work today as I didn't feel like working on the shell, got a few bits tidied up and back on the engine, starting to come together now

Here's a quick pic from yesterday though, sanded and primed up the outer sill and doorstep -

So, to today's progress, wire brushed and painted up the clutch parts, new thrust bearing, new O ring, new pins and new split pins. Also greased up the hole where the arm sits -

Fitted back into the bell housing -

Fitted back onto the engine with new Smiffys stainless bolts, torqued down and the end float set to the correct distance (6.5 mm according to the Haynes manuel) -

Next up was the timing cover, primed the chain and sprockets with oil and wire brushed all the bolts. Then I centred the cover using the crankshaft pulley and screwed the bolts in finger tight, removed the pulley and then torqued down

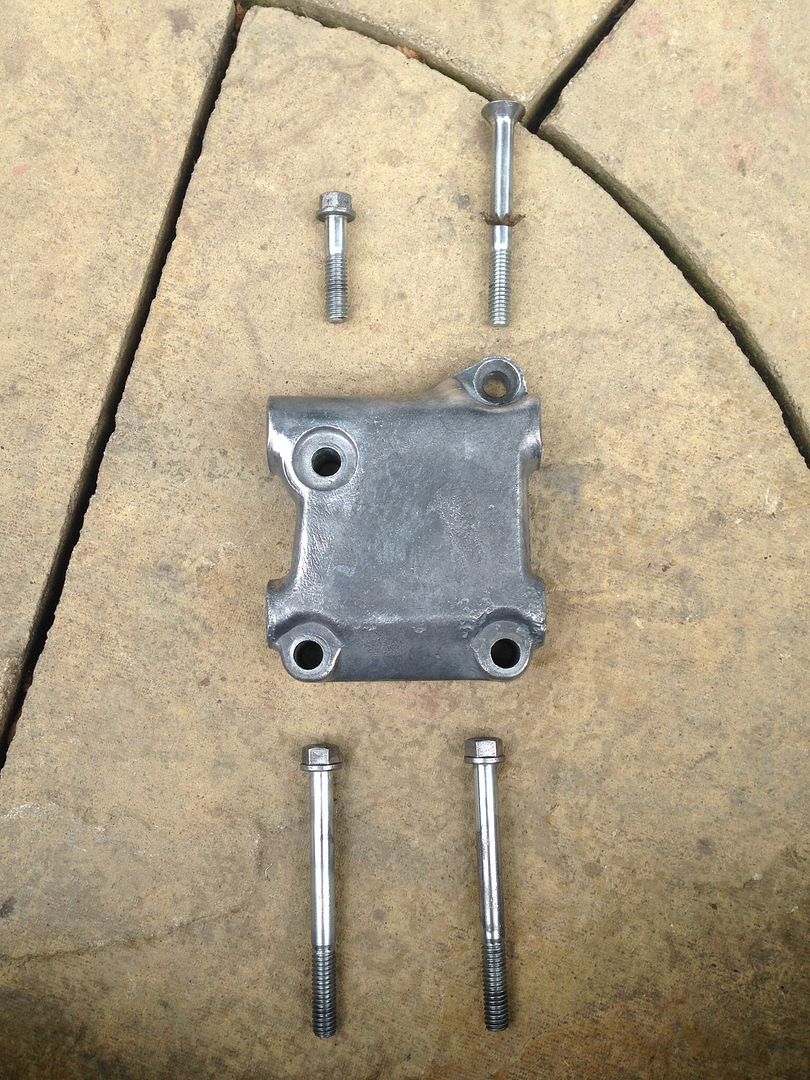

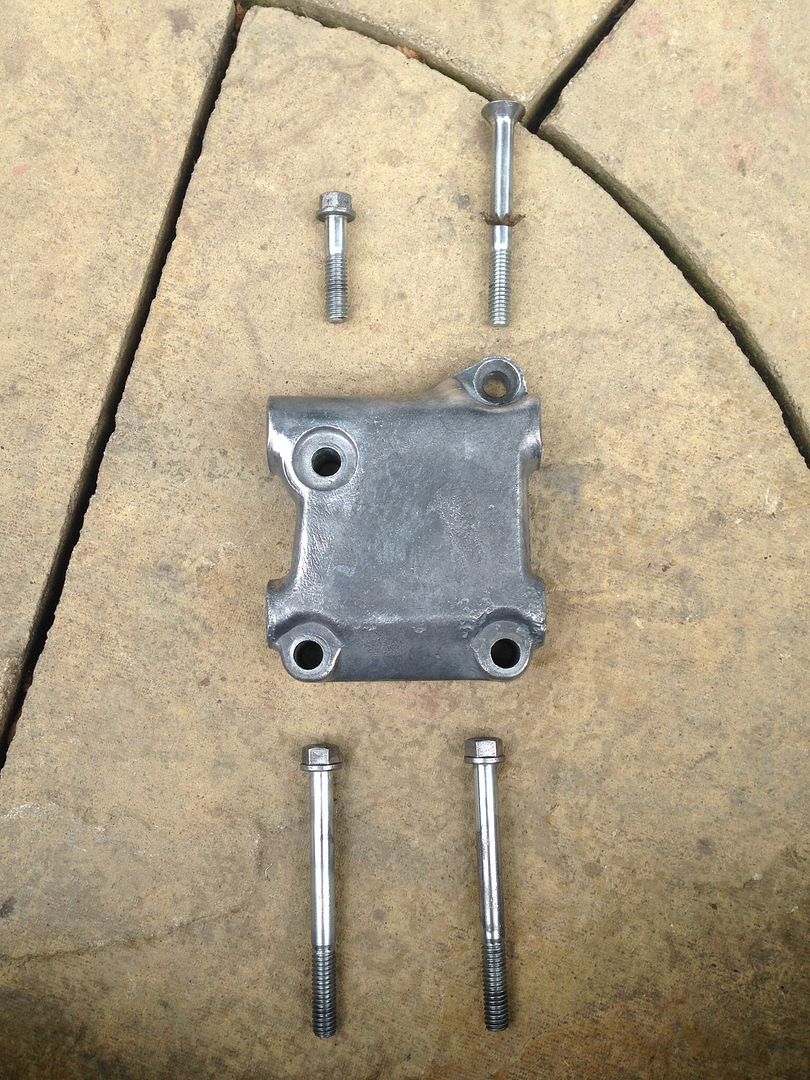

Then I cleaned up the engine mounting and fitted that back to the block -

New bypass hose, (new water pump to be bought soon) -

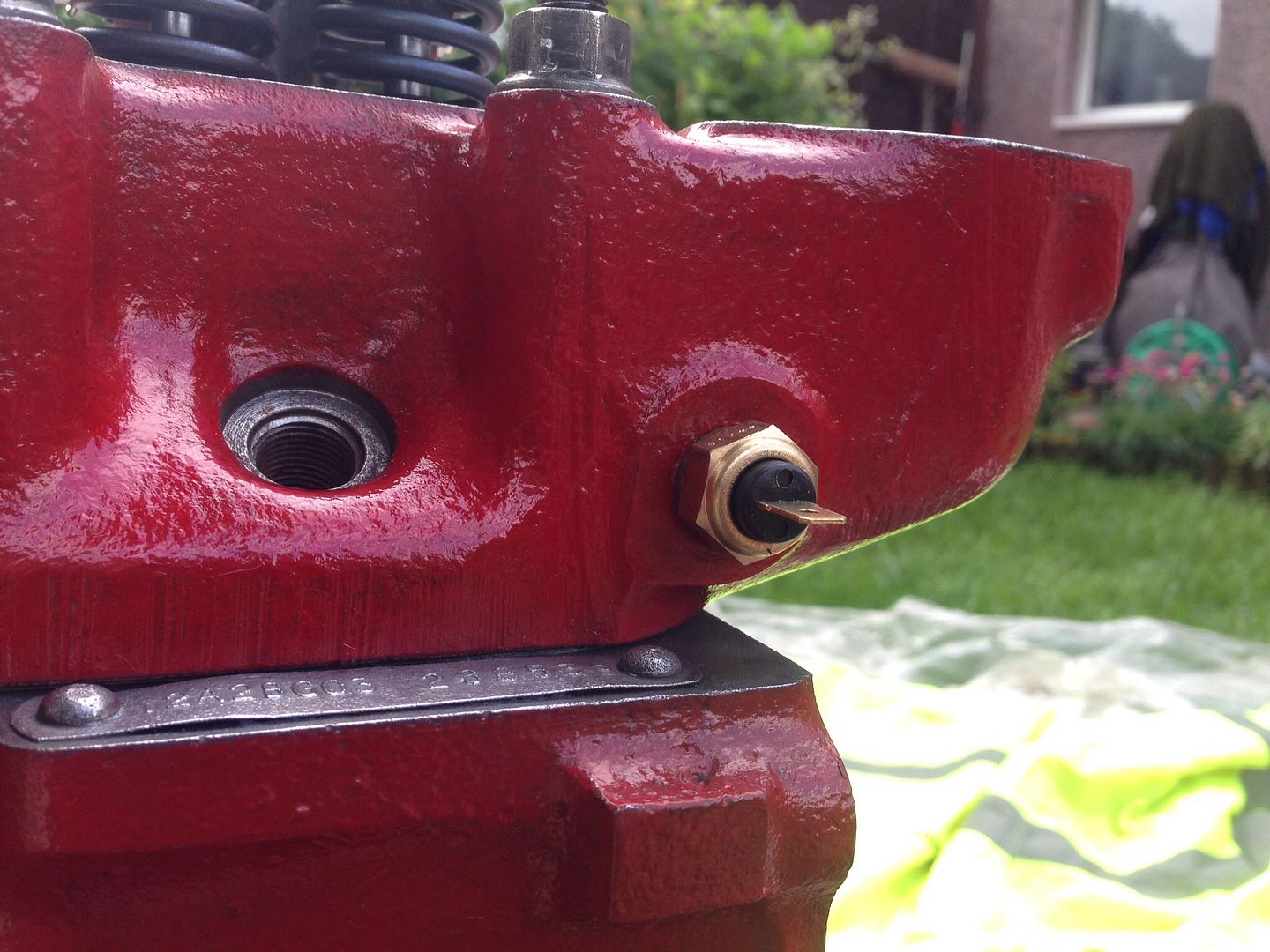

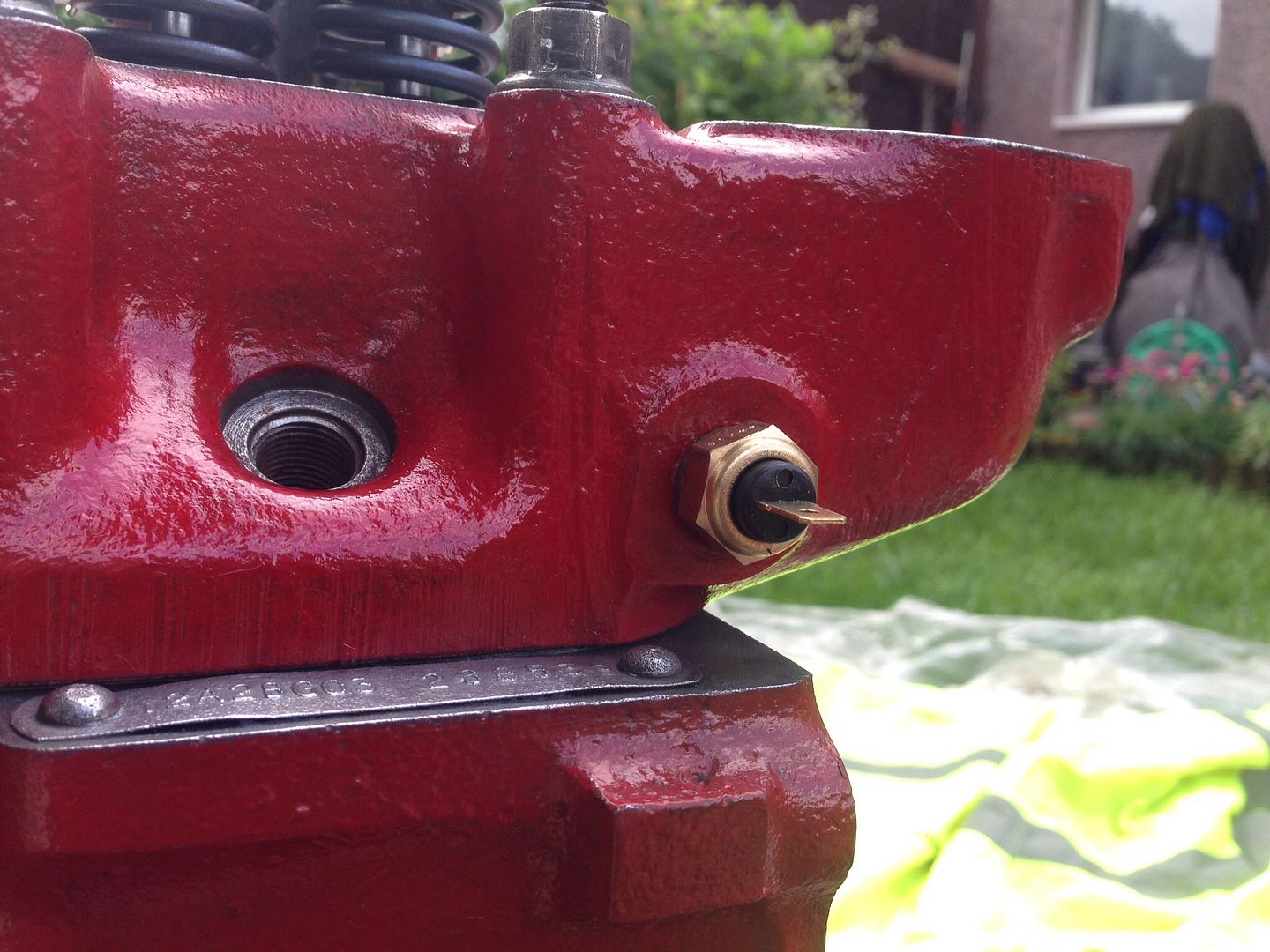

New temperature sender -

And I also touched up the block with some red paint where it was needed. Here's a few snaps of where I'm at now -

That's all i got done today, spent most of the day looking through the Haynes manual for torque settings !

I've also got a quick question, does anyone know what the torque setting for the timing cover bolts is. There's two settings in the Haynes manual (1/4 - 7nm & 5/8 - 16nm) and I don't know which I need. My bolts need a 3/8 socket to tighten them so are both of those settings above irrelative to me ? If so what do I need to torque them to, as I've currently torqued them to the higher 16nm, kind of confused about this so any help would be great !