ok big update :)

soooooooo first today i picked my mate Matt. He kindly offered to do some welding for me, as i dont own a welder

first call of the day was to pick a pair of metal plate off cuts from a fabricators locally, they were 6x6 inches each and 1.5mm thick.

this is to strengthen the floor where the bottom mounts for the subframe are.

heres Matt welding them in

and finished, with some nice M10 bolts and nylon locks with mahoosive washers

and both

i then began to start making a good surface to paint on for the lower part of the engine bay

then i cut out the bottom bit of the bulkhead, as i know i need to make space for this manifold, but until i can place it and see how much i need to cut out, i guessed this for now, as soon as i have the inlet i will cut anything more i need to :)

time for a tea break! mmmmm biscuits mmmmm

anyway! on we go

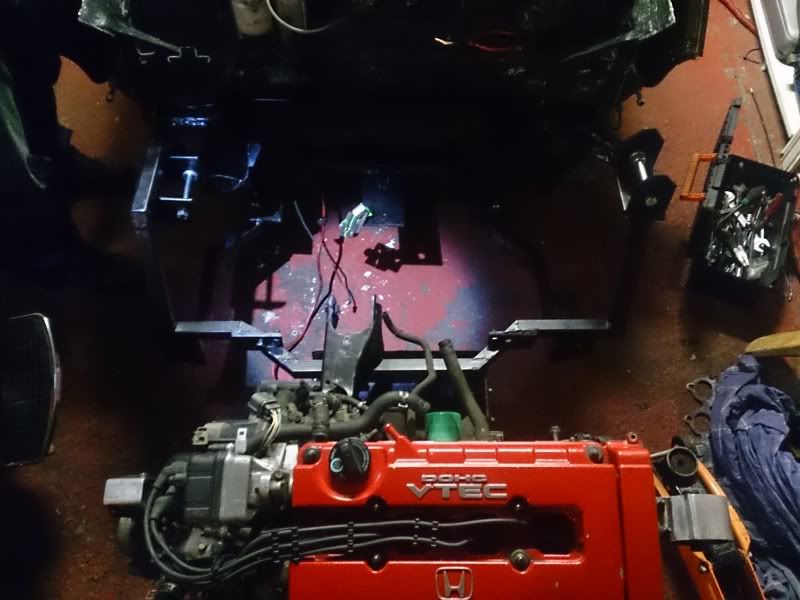

so were at this point now

and finished stripping the old subframe

and in comparison to the new one...

then i got stuck with the subframe with getting the cones out, so i just gave up and cut them out!!! in fact both of us cut a tower each at the same time lol

nice bit of water in there aha! looks odd from above aha

after taking all of the stuff of, i have put all of the nuts and bolts in a glass full of gunk mmmm so a week of soaking they should be good :)

then drilled the new holes for the subframe through and went for a trial fit, it went really well apart from having a small space on one side and a bigger space on the other side :/

and the bottom mounts were pulled in so they were ok

and then ended up cutting the last bit of the bulkhead so there wasnt a stupid lip on it lol

then this happened by accident :)

whoopsie!!

the conversation went like this,

"shall we?

erm, i haven't got an engine crane....we could probably lift it?

yea go on then"....

it carried on like this for a bit, looking at the best way to do it, we had a big plank with tow rope, we had a stool, cushions, wheels, car jack, after fidgeting around with this for a bit, we said b******s to it. and we just lifted it in, gearbox first then the rest! lol went well :)

the engine cleared everywhere which was awesome

and to be honest, im loving the camber a lot and if i didnt have my wheels i would definitely go standard 10 wheels it would look badass like this

thats it for today!

till next week!

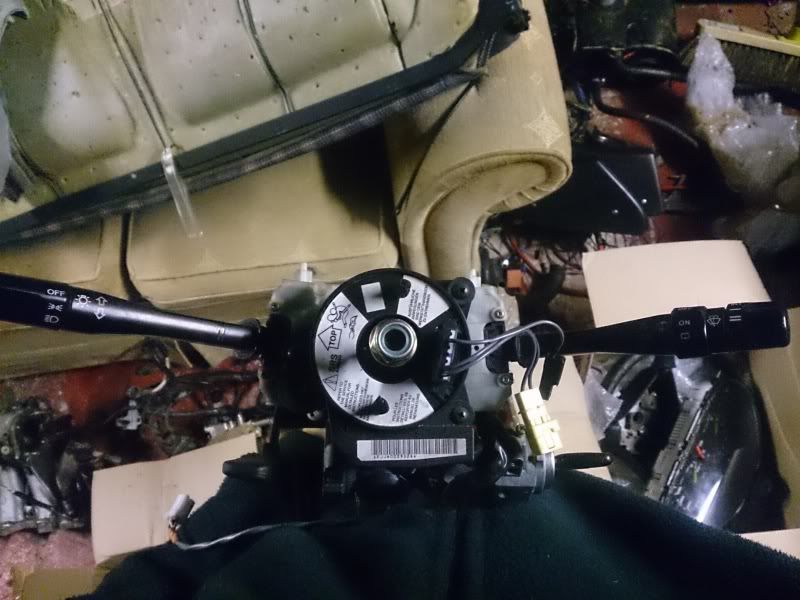

next week, wiring mmmmmmm

steering column (strengthen and decide to use the mini one or the honda one)

checking the clutch

cutting and welding the rest of the bulkhead to suite manifold

fit inlet manifold

![]()

![]()