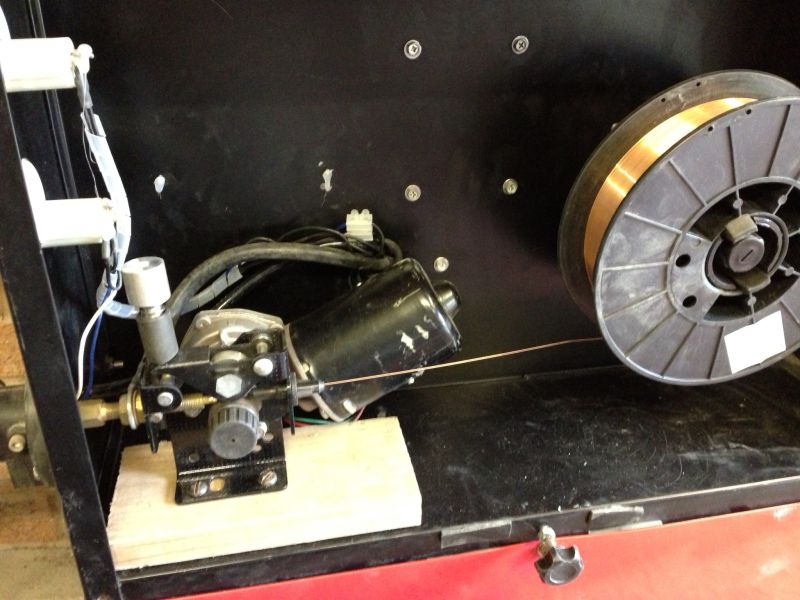

The one i found with my Clarke is if you get burn back on the tip it causes the wire to bunch just after the feed roller. Make sure the wire speed is fast enough to prevent burn back.

Butt Welding Issues

#31

Posted 21 October 2013 - 09:33 PM

#32

Posted 21 October 2013 - 09:35 PM

When you change to 0.6 make sure liner in good condition as it doesn't feed as easily as 0.8, I ended up replacing my liner as it was causing judder on start up even with new rollers and tip. You need a good consistent feed when welding thin material.

just out of curiosity, what would cause a liner to fail?

Damage to the wire itself, when this travels up the sleeve it can cause pickup inside the liner which will then drag the wire down in speed no matter what speed you have it set to.

#33

Posted 21 October 2013 - 09:54 PM

#34

Posted 21 October 2013 - 10:02 PM

Certainly not got that adjustment ability on my Clarke. I have next to no gap anyway but it will still bunch up. Just a poor design but with care and the wire speed adjusted it does not happen that often.

#35

Posted 22 October 2013 - 03:20 PM

hi, if I needed a new liner for my clarke 151TE, which material would people recommend - plastic, metal or teflon? Thanks Notay

http://www.machinema...ing-consumables

#36

Posted 22 October 2013 - 04:08 PM

I bought a new torch which included the liner etc of fleabay for not a lot of monies. Teflon lined if i remember rightly.

#37

Posted 22 October 2013 - 04:18 PM

It easy to test your liner just lift top roller and see how easy it is to pull the wire from torch end, it should be smooth and easy to pull.

http://www.mig-weldi...ead.php?t=21324

#38

Posted 22 October 2013 - 05:20 PM

hi, if I needed a new liner for my clarke 151TE, which material would people recommend - plastic, metal or teflon? Thanks Notay

http://www.machinema...ing-consumables

I always go for a steel liner as I will only ever weld mild steel with this welder but Teflon if welding alloy or stainless

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users