Next up, rear valance closer plates and reinforcing plates for the rear subframe mounting.

I used heritage ones, as I had nothing to start with, and they came with the reinforcing plate, already spot welded together.

However , after a trial fit, they just didn't seem to fit right, and I wasn't happy with them. So I decided to split the parts, and mount them one at a time.

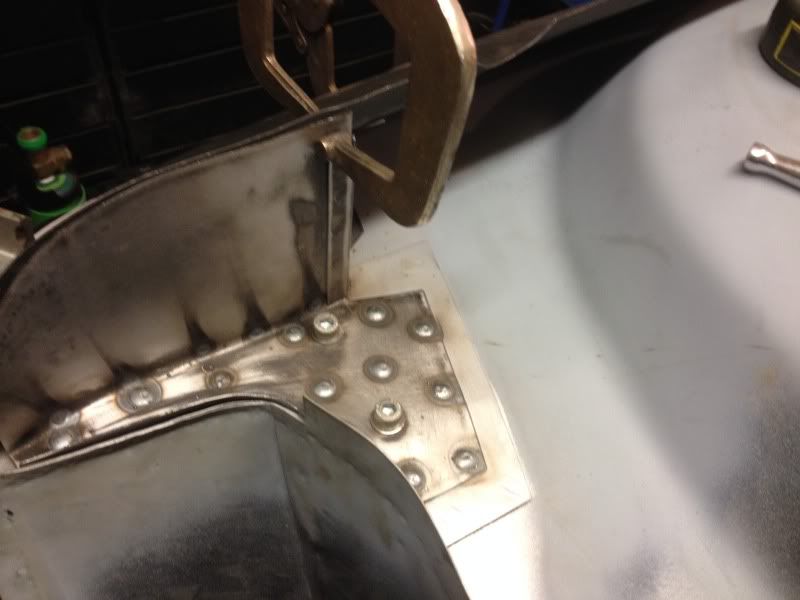

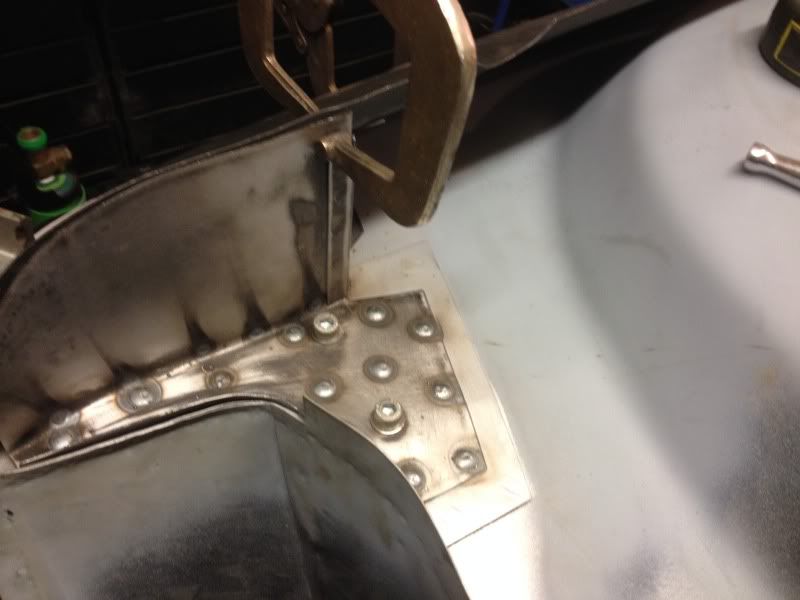

Spilt

As you can see, not a lot between them , so glad I did split them really.

I prepped up ready to fit the plates, and used weld thru primer on the mating faces.

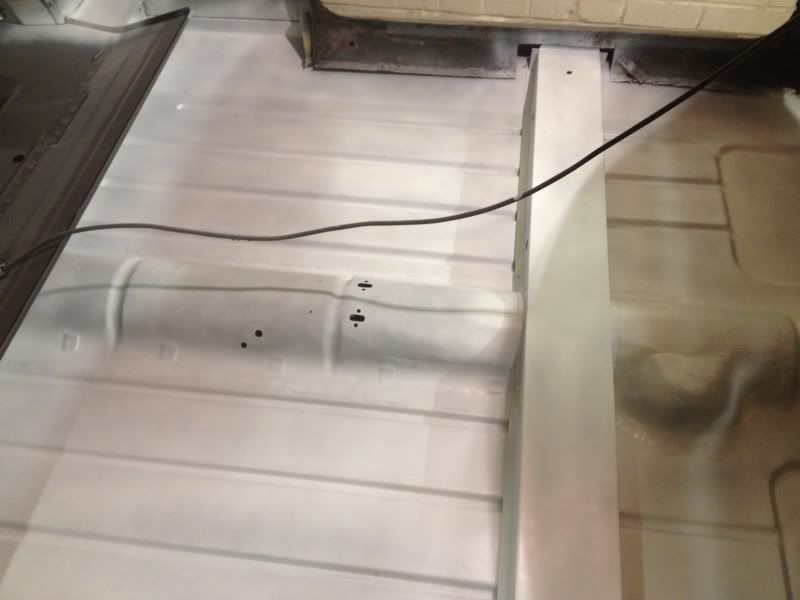

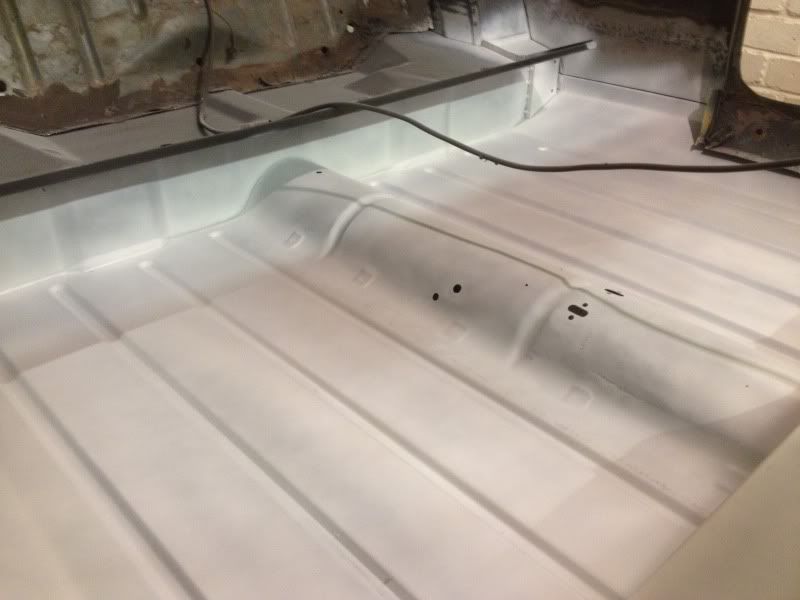

I used the subframe holes as datum on the boot floor to position the plates, and both plates sat nice and tru in relation to each other, and also ran parallel to the the wheel arch edges.

Happy with both of them,gotta lug welded them, then flushed them back

Using the mounting holes as datum again, I started on the closer plate piece. This proved a lot tricky than I thought it was going to be. The main problem I had was my pattern rear lower valance. It came with the car, and As I'm on a budget, I got to use it. It will be ok with a bit of work, but it needs to be fettled to suit the closer plates, but as mine aren't fitted yet, that's tricky. And I need the valance on to help position the closer plates . Hmmmmmm . So the only way was attack it until it looks right!

Lots of clamps needed for this one!

After a lot of jiggling and bangin, I got a fit I was 97% happy with, and as I wasn't planning on fitting the rear valence yet, I decided that was enough , and to fit the closer plates.

I decided to weld them on with the lower valance clamped in position too, as its all going to help keep things in the right place when welding.

After these were fitted , I closed up the lip on the rear wheel arch face and closer plate, and seam welded them together. In my true style though , I forgot to get pictures of this, as the next step was to turn the car the right way up, as Ive been looking forward to that moment for ages!

Thanks