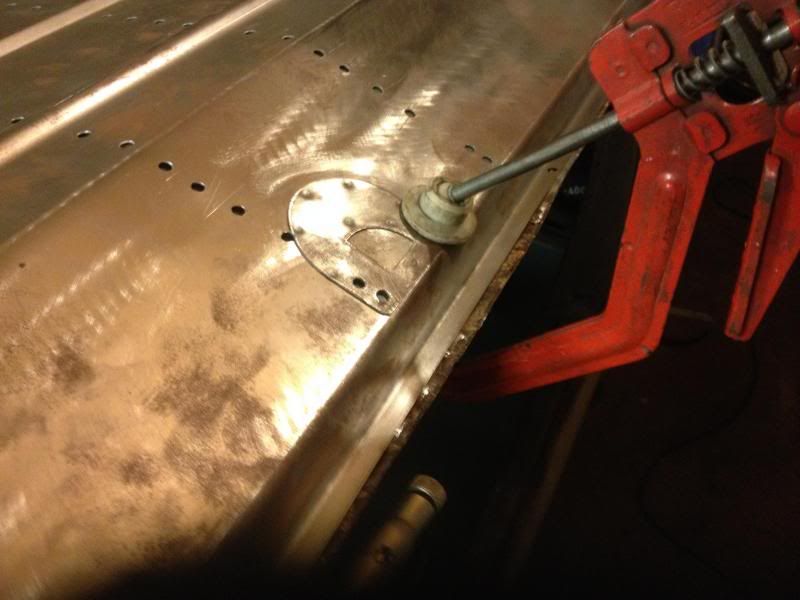

Welding looks "spot" on to me !!

Back corner near the brake bias valve looks a bit suspect in the last picture, and the Cone mounts probably look worse than they really are. Why have you got two engine mounts (well one and a half !!) fitted to the back of the rear subframe ?? Exhaust mounting ??

Phil.

Thanks phil for your reply. The brackets you mention, which I now now are engine mounts' were on there when I got it. The exhaust wasn't fitted to the car so I can't confirm if it was hanging from them, but I think you may be right!

I will have a bit of a session with the wire wheel to inspect the corner you mentioned, and I will get some pics up of it when I can ..

Thanks again

I think the remains of the cones, well the metal band is still attached to the sub frame, doesn't look to bad otherwise IMO but check into the corners as Phil has mentioned above

Thanks udo for helping me. I will have a closer look at that area and report! So, fingers crossed I may be able to scrub off the rear subframe from my shopping list. Woo hoo, my list is now down to only 8,675,543 parts!

Looks like it may be going to shot blast then if the corner cleans up ok !