looks cracking mate whats your plans back to original? im loving that little air scoop on the scuttle never seen one like that before. is there much rust on the floor panels like mine? cheers tom

Thanks Tom! Plans still undecided really mate, going back to 90 %standard at a guess , but that is subject to change as always.

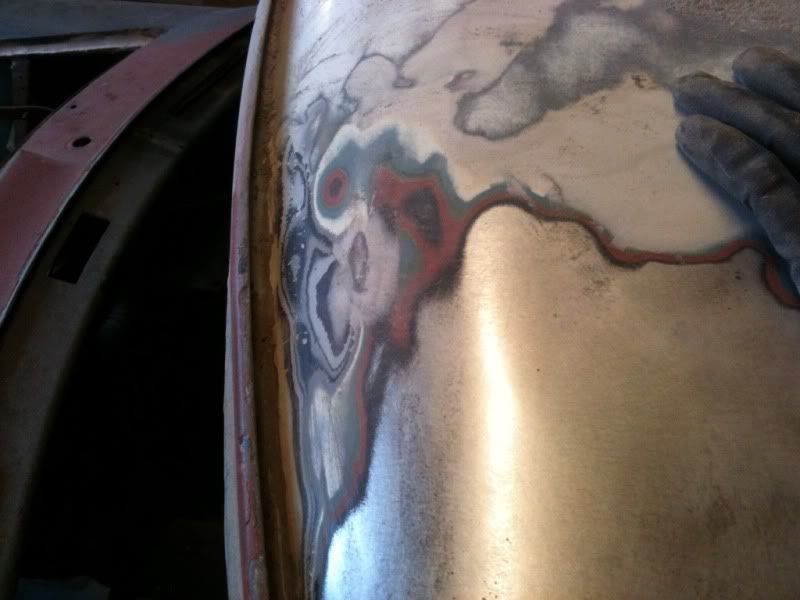

She was quite rotten Tom, but you've definitely won the rustiest car challenge !. Ive had to replace basically the whole bottom of the car, (managed to salvaged the centre tunnel though ) and various other repairs etc from rust and modifications people have done over the years ..............you will see what I mean when I get the 'paint sanded off' photos on here !