We've got a bit more room to move over in Canada so everyone like big garages for some reason. This one has heat now too so even better than ever!! Keep it at a mild 45 which keeps the chill off when it's 0 outside or worse. It also keeps all the paint cans and such from getting fubarred!!!

Onto the car again...

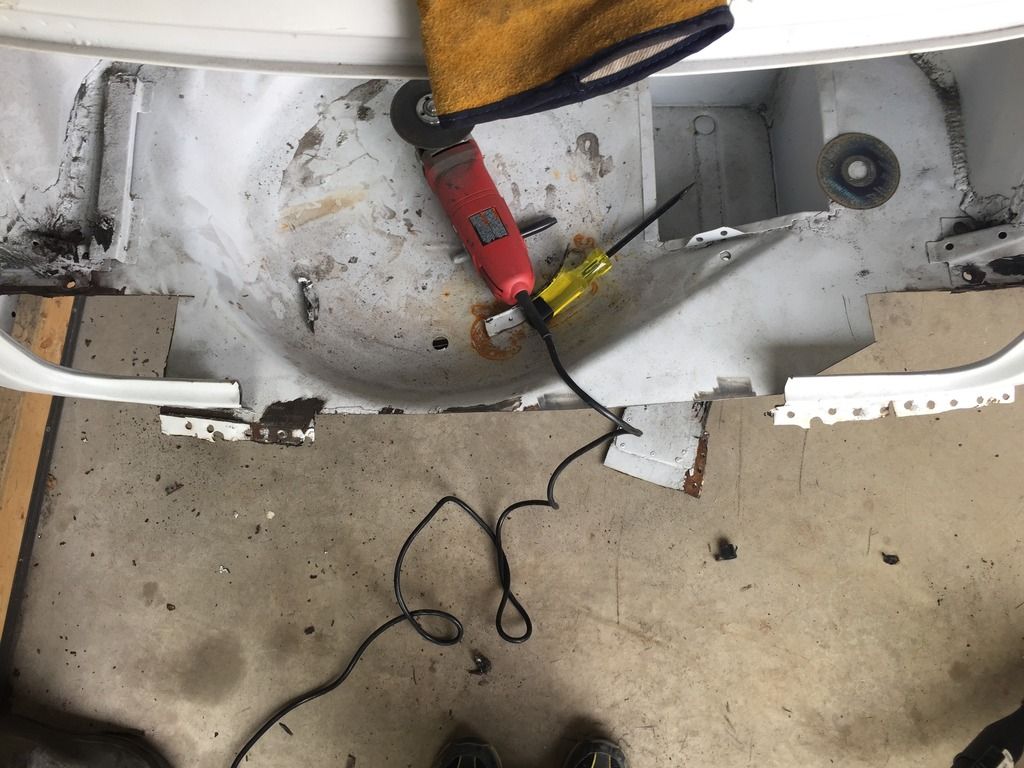

Pulled off some old rust and got the sill and rear bottom quarter panel ready for replacement. And some Guinness just because

Then set up some practice pieces for doing up some plug welds. The last ones I did were terrible and had to pick up a new piece. This is the old one!! I didn't take any pics of the finished product but figured they were good enough!

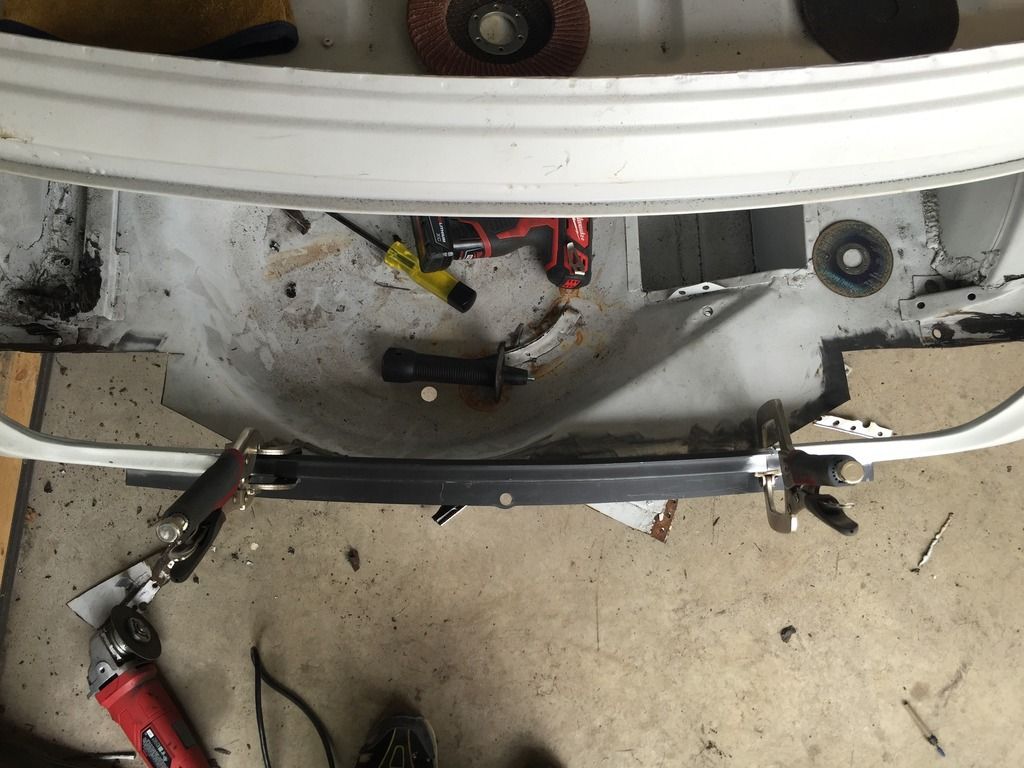

Then off to doing it on the actual piece I guess....

Not too shabby for first go and a bit of the grinding on the bottom of the pic too worked out ok.

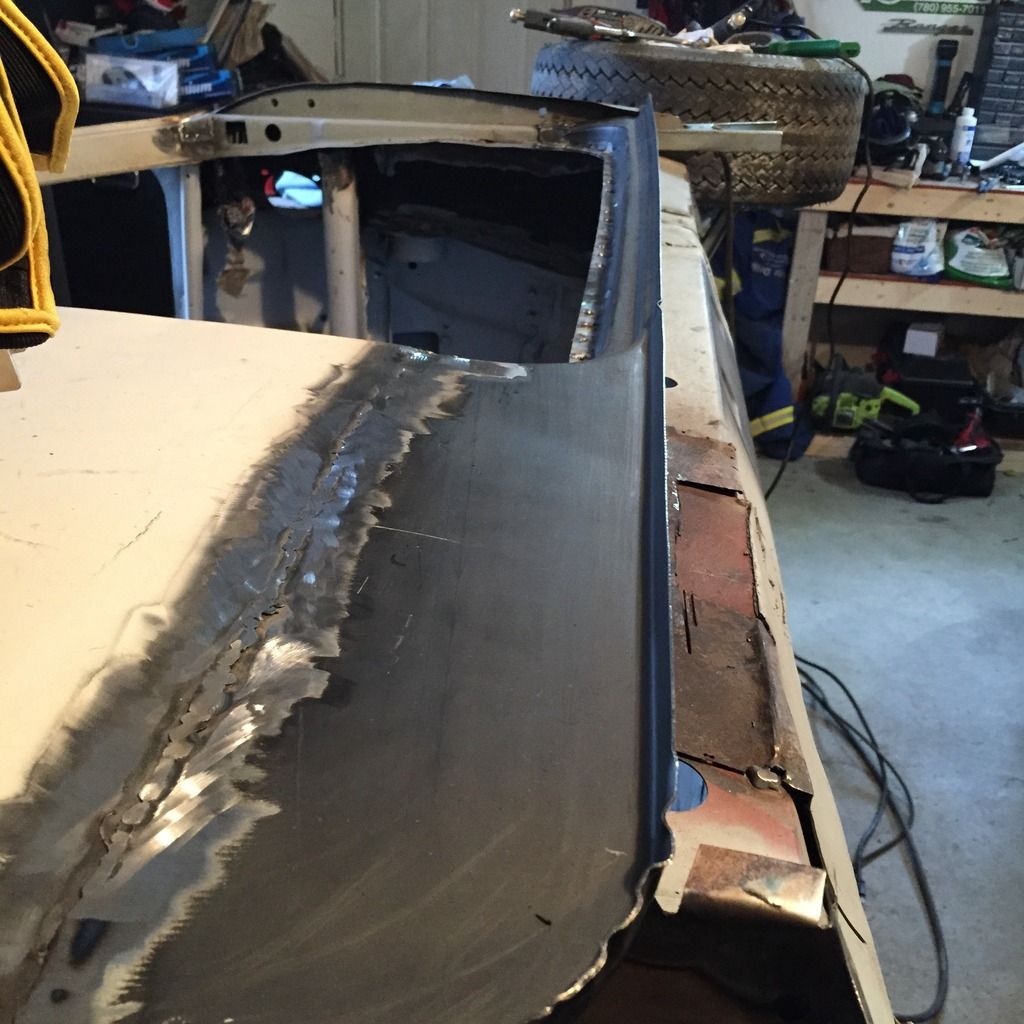

Then off to the body welding...not as good

It will require some bondo but it will work out once the grinder has a good go at it. Also need a bit of grinding on the inner sill joints too.

This will take time but it will hopefully only get better on each go around.