Got the arch in today along with the closeout. Bit of a faff with the subframe jig in place but it was worth doing that as i found an issue which i managed to sort out without any grief later on.

Then it was out with the companion bin

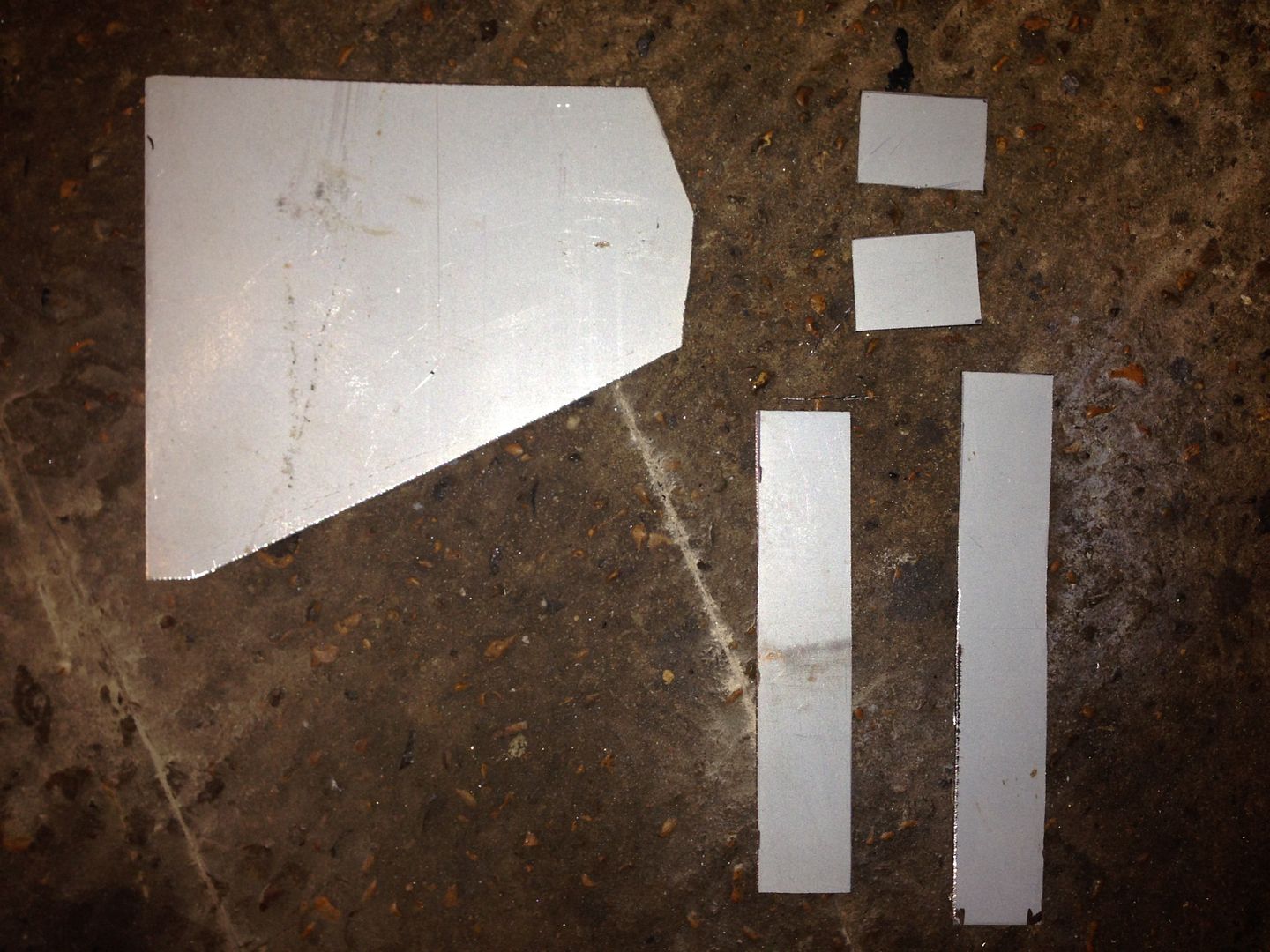

and even for a car of this age (1979) there was still bits fitted without any paint as this section of the companion bin shows