Just sepnt two days reading the whole thread and there's some amazing work gone into it. A real credit to you Neil!

I bought my first mini on the weekend after wanting one for years . Will have to carry out some repairs on it myself hopefully not to this extent though, also need to learn some welding skills first though.

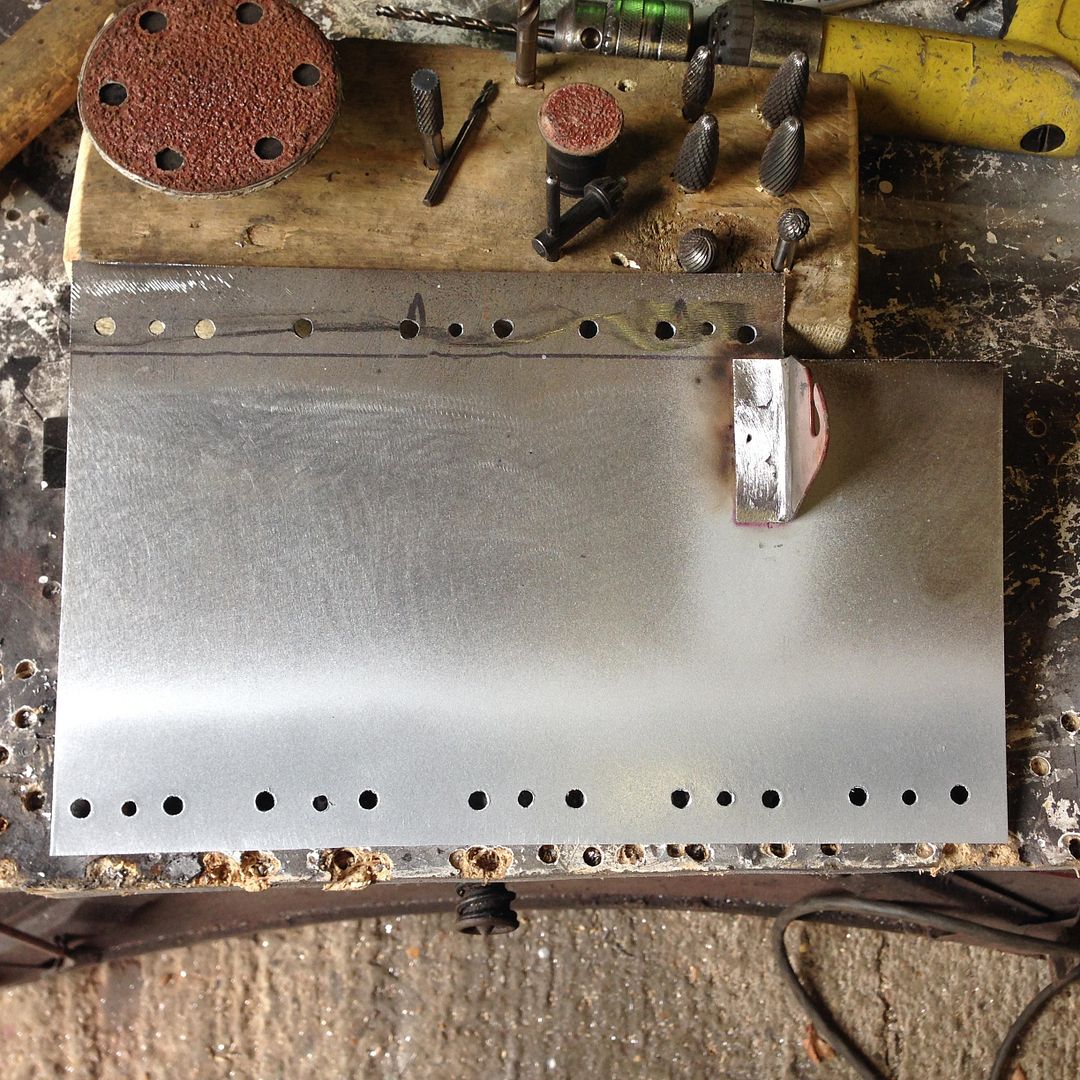

Anyway keep up the good work Neil, almost finished