Well well well, I've been very lazy with my updates indeed! A lot has happened, and this may take a couple of posts to cover, so bare with me!

Reading back over the last few posts of my build thread, it appears that it was back with the painter having some errors corrected when I last updated. Well, the car is back now, and for about a week or so it looked pretty good. The paint sinkage is still visible in a few areas, and the eggshell on the passenger door is just as bad as when I sent it back. The problem now though is that after having the car back fro a few months, the blistering on the engine bay crossmember and around the lights has returned. I paid an extra £350 for him to strip the car back to bare metal and start from scratch from the A pillars forwards, but I am almost certain that he just flatted it all back, buffed it up and crossed his fingers...

So, I have decided that he is a cowboy who will never do the job right. I know some people may think this is a bad idea, but my plan of action now is to just get the car built and on the road so I can enjoy it for a bit, while keeping a VERY close eye on the blistering areas. I will take it back and give him one chance to fix the areas around the lights for free or I will take it elsewhere. I've been doing some research and I have a few reputable places lined up for consideration.

Here are some pics of what I'm on about. At least the areas on the crossmember will be hidden by the carbs, it's the front that I'm more worried about.

Right then, enough moaning.

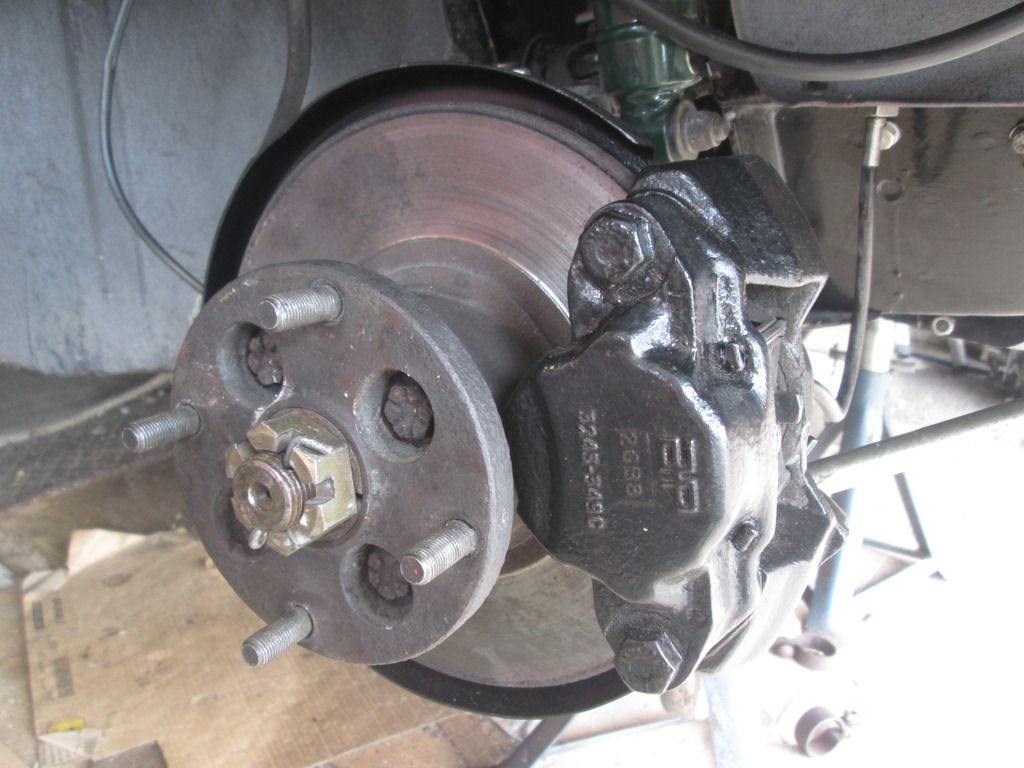

The first thing I did when I got the car back was re-fit the front subframe, and the very spur of the moment, I decided to solid mount it flush to the crossmember similar to the way the Miglia cars are. After doing a lot of research I cracked on, firstly chopping up my poly bushes so that the bit that locates it into the crossmember was still there (a lot of people simply remove it altogether which I decided against)

Last photo is rubbish, but you can see how much distance I've gained. Should mean I can run a little lower without upsetting the suspension geometry too much.

Obviously the rear subframe mounts needed a lot of fettling so fit now, which involved redrilling pretty much every hole on the car, subframe, and the mounts themselves. I forgot to take pics of this annoyingly but Ill get some of the mounts fitted to the car soon.

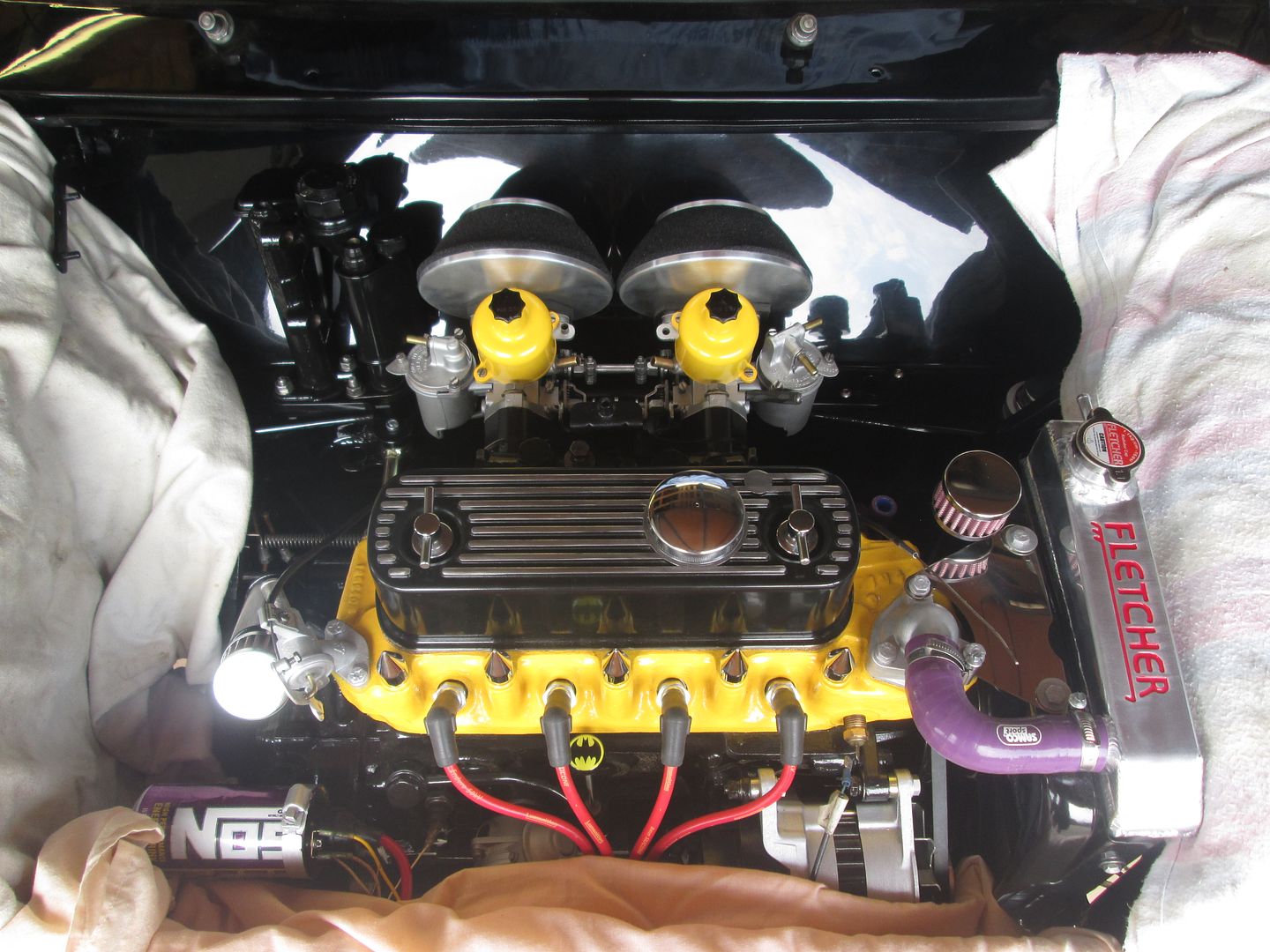

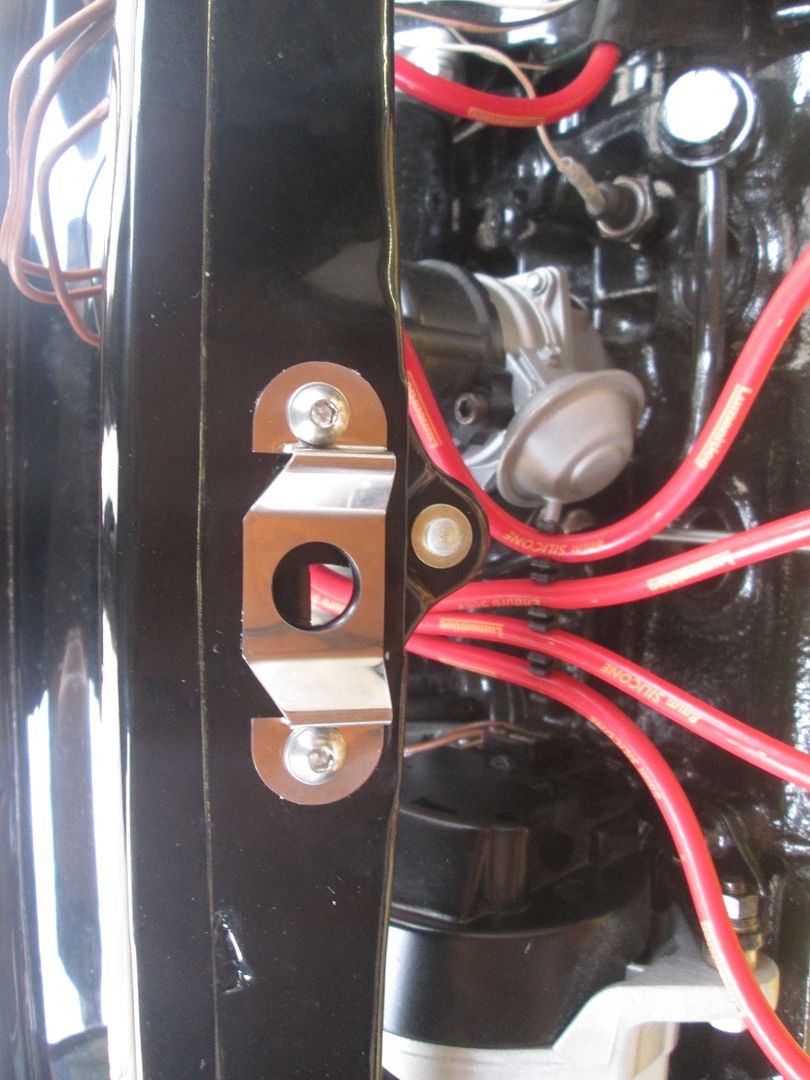

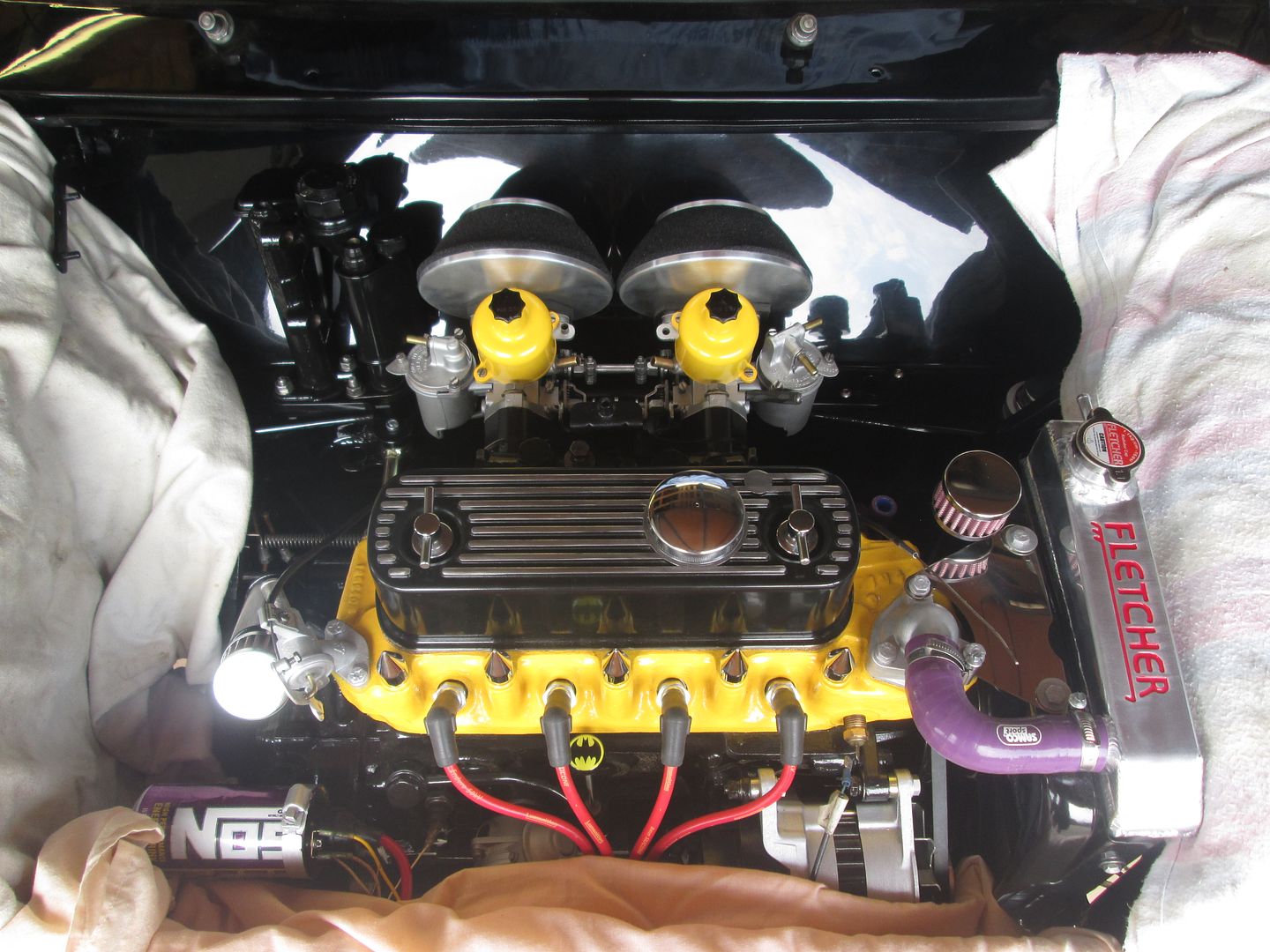

Next up was a big milestone for me. ENGINE TIME!!! ... I borrowed a homemade engine crane off my neighbor, and with the help of a mate and a few straps, we had it in surprisingly quickly! Took quite a while to get the engine mounts to line up though, got there in the end though.

You may also notice that the car now has a face. Here's a few pics with the grille as well. Everything behind is a bit exposed for my liking so I'm going to cut some mesh to go behind the grille and paint it black.

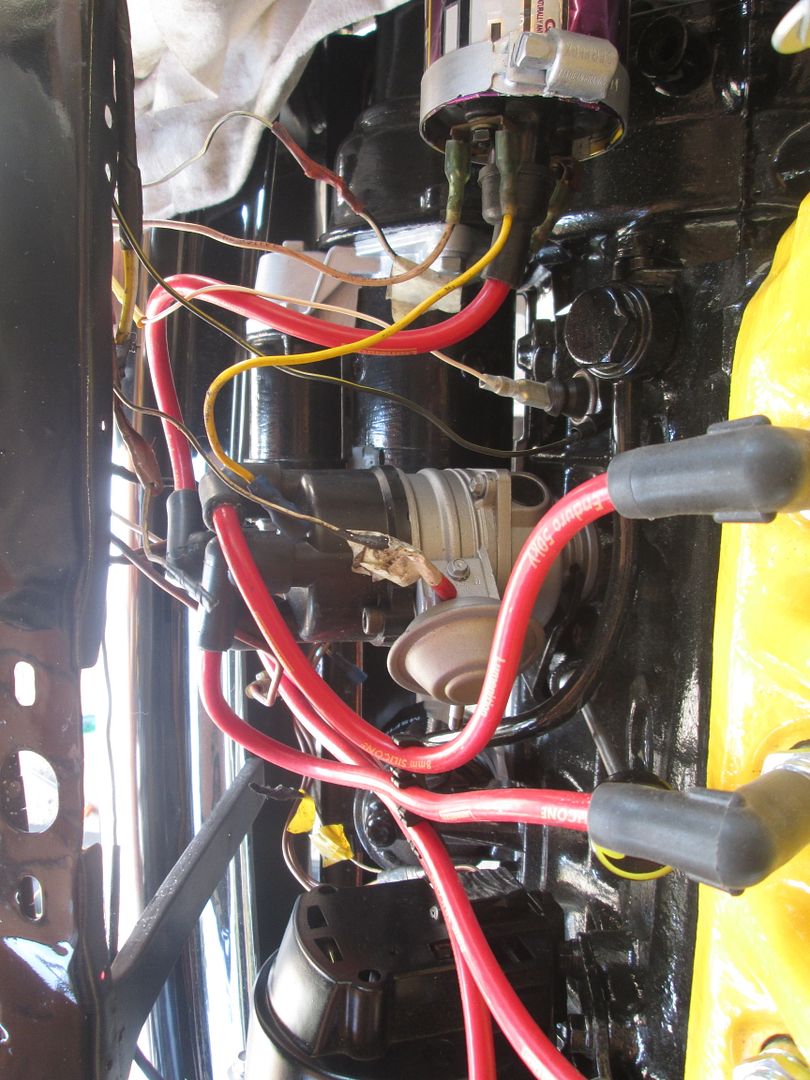

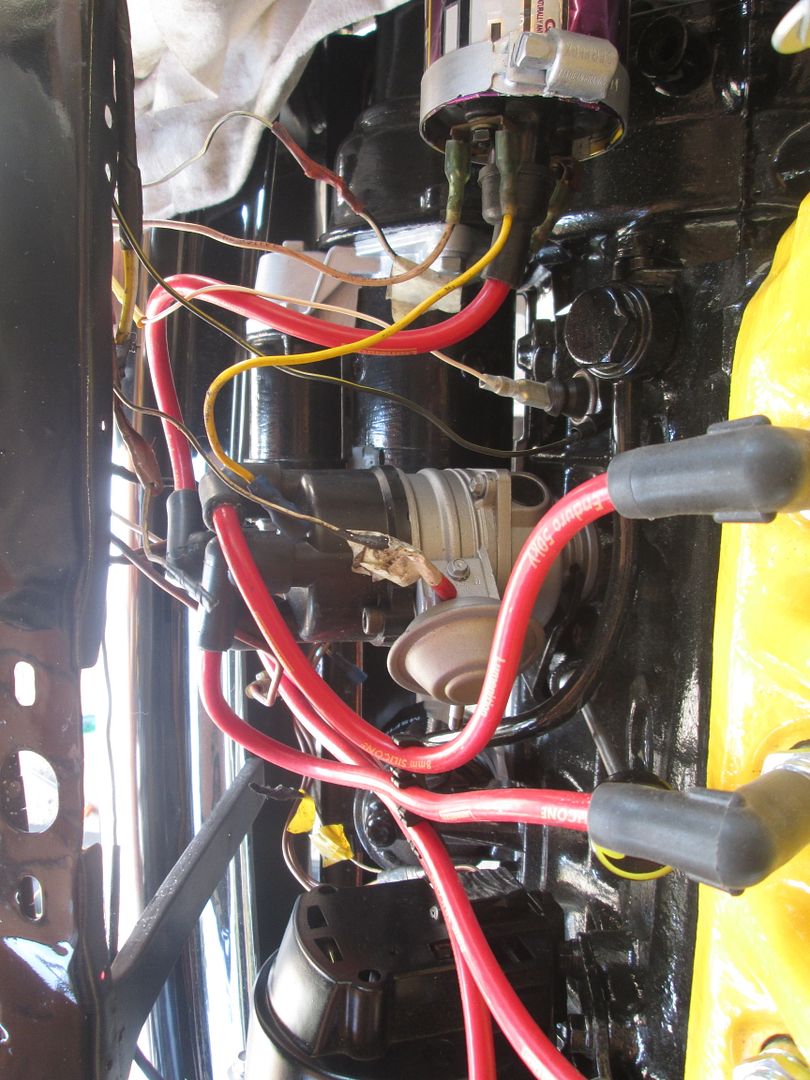

Trying to get my head around the wiring. It'll all be hidden away when I'm done.

Got myself some Pipercross filters for the carbs as they give much better clearance (plus the black looks cool).

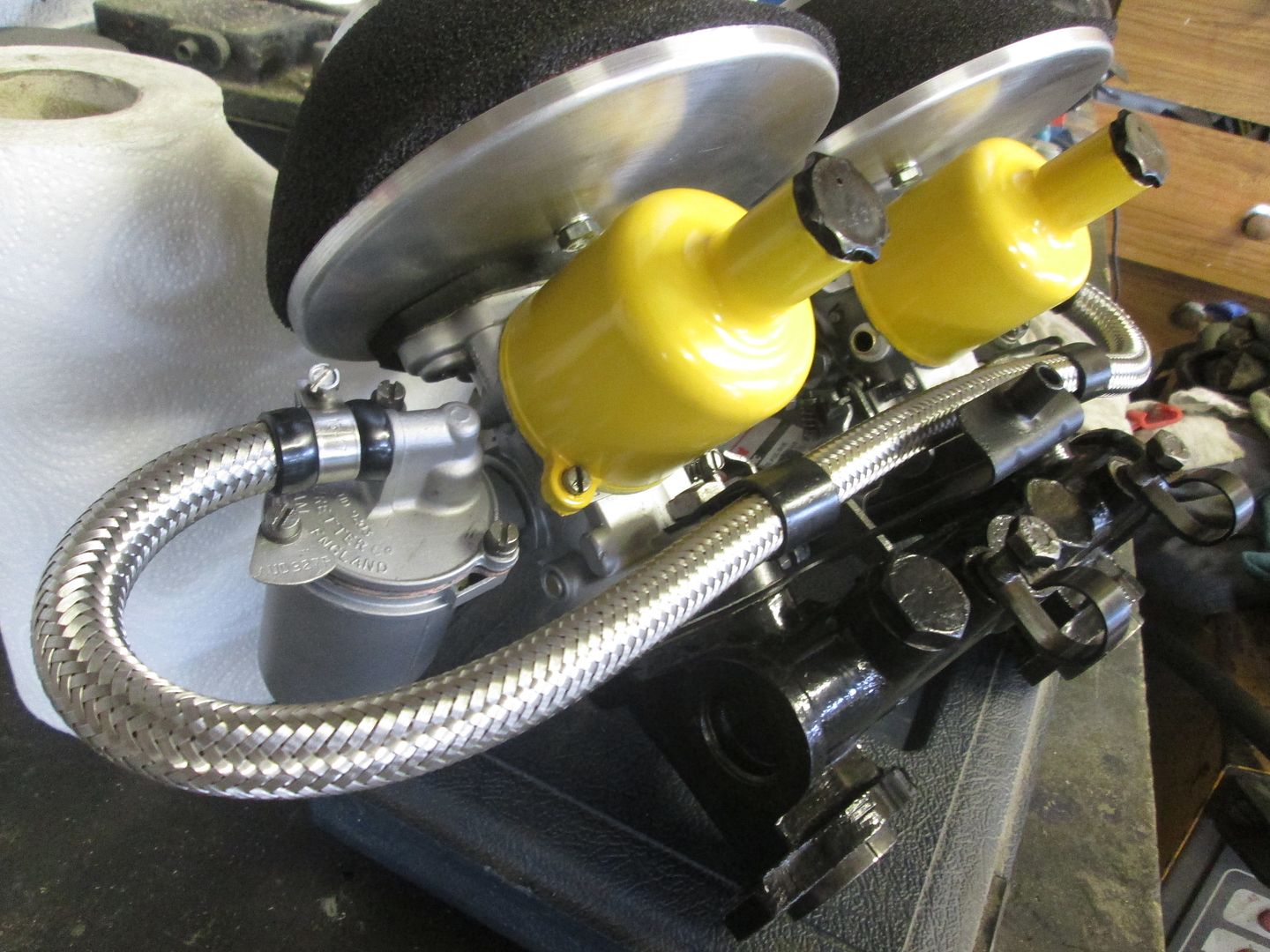

Bought an adjustable engine steady to pitch the engine forwards a bit so the carbs would fit, then mocked them up.

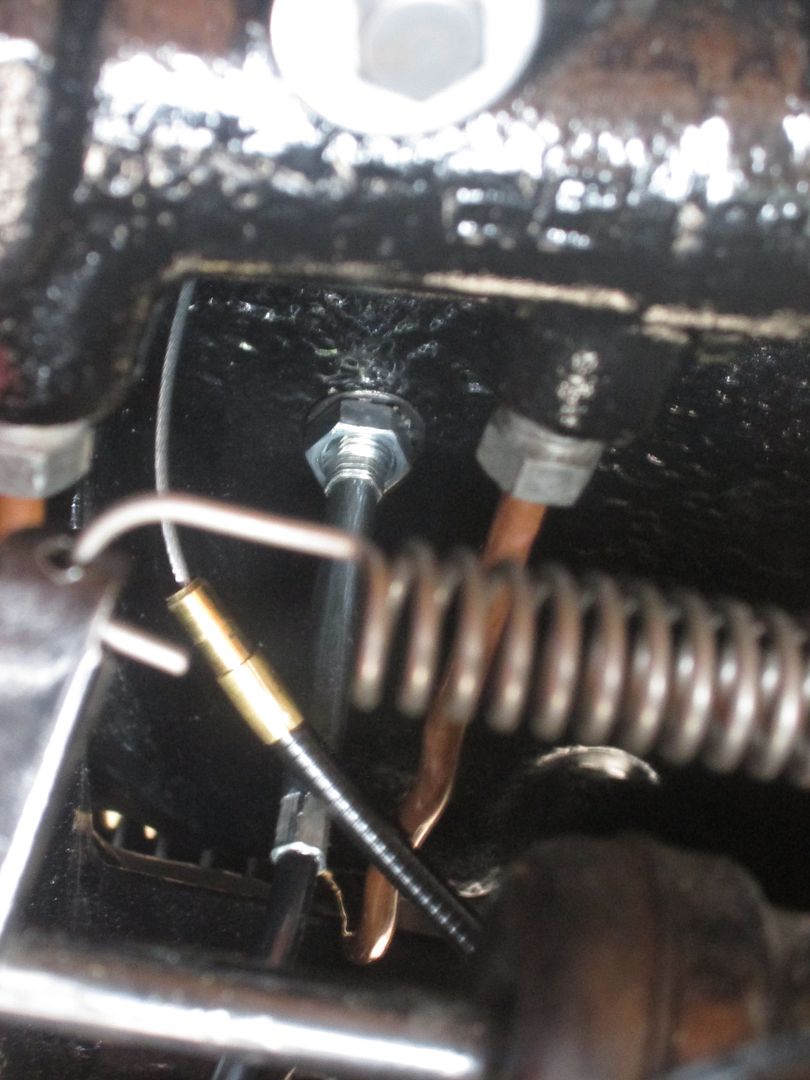

However, this presented another problem. Due to angling the engine forwards so much, it changed the angle of the downpipe so that the bend at the end pointed up into the floorpan slightly, instead of down the length of the car. This meant I couldn't get the Y piece on (raising the subframe probably didn't help either).

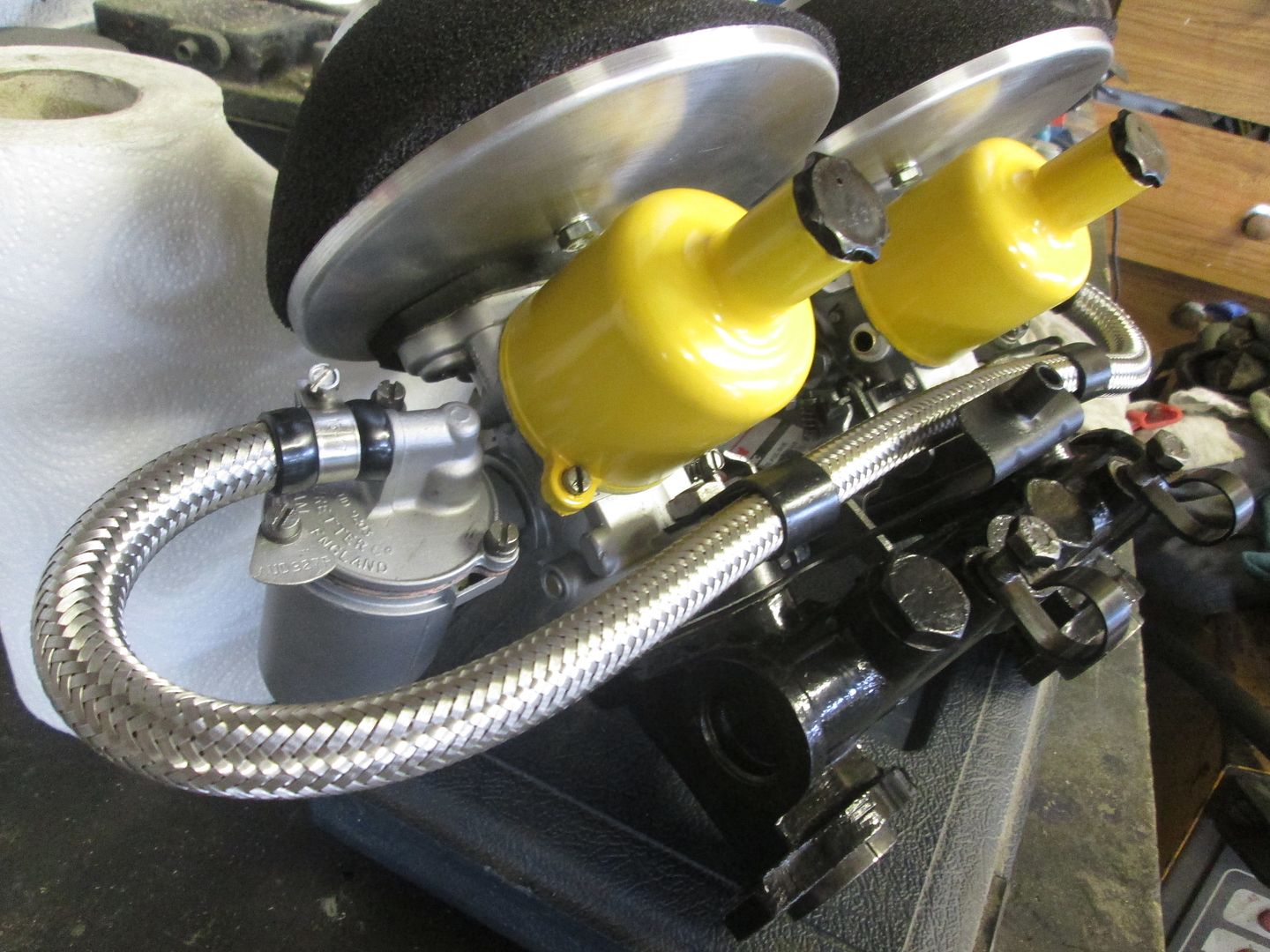

If you look at the pic of the engine steady above, you can see how thick the spacers on the carbs. This had to change, so I dismantled the carbs and sawed the spacers in half.

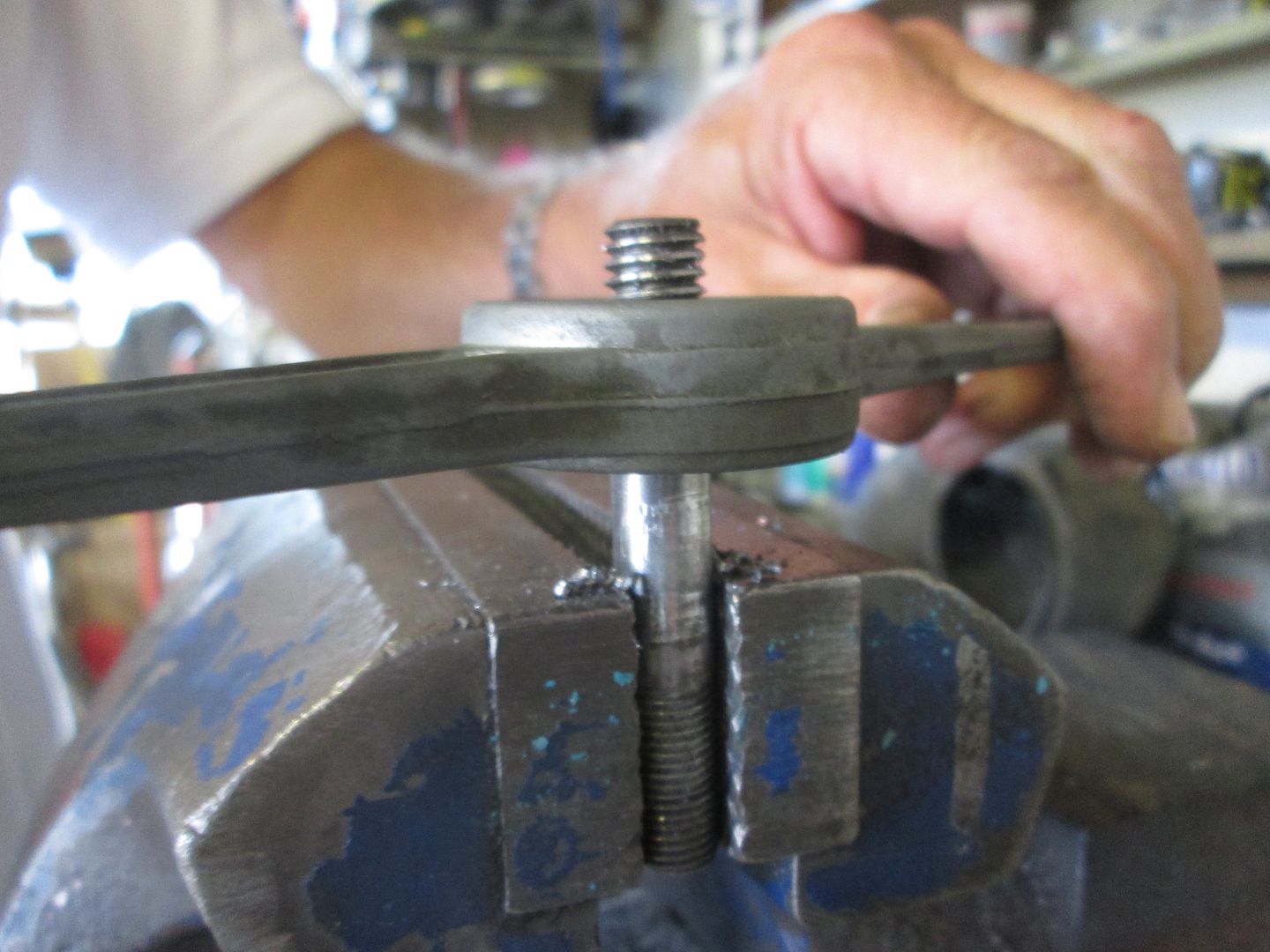

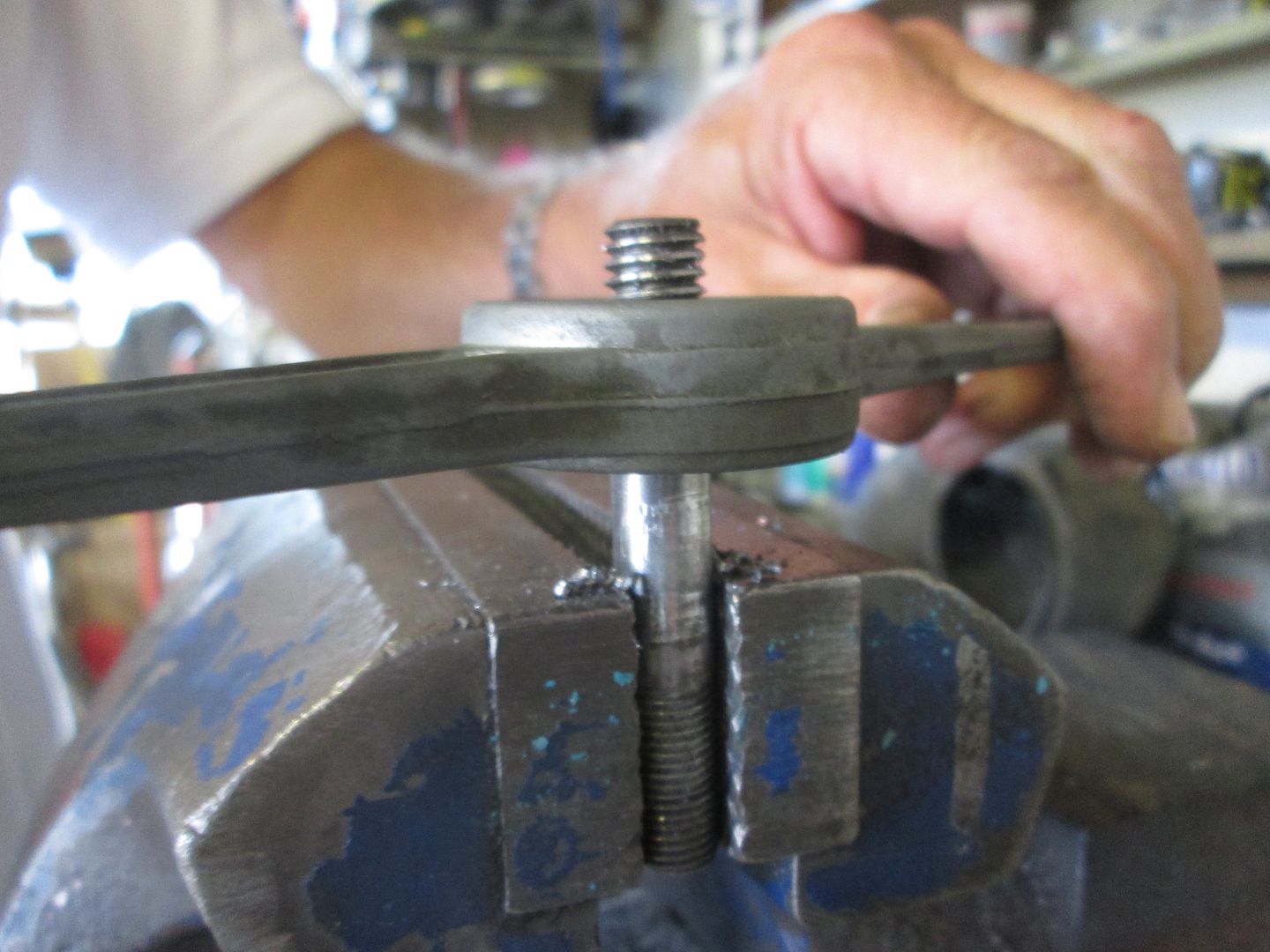

After this, I then had to shorten the studs on the manifold, and after lopping a piece off the end I then tapped new thread onto each stud.

The next problem was that the throttle linkage now hit the heat shield quite significantly due to the thinner spacers, so I fixed that problem by cutting a big hole.

If it looks stupid, but it works, then it's not stupid!

Obviously this now renders the heat shield useless, so I shall be wrapping my exhaust manifold in insulation wrap.

All reassembled with some braided hose for good measure.

The shorter carb spacers now mean that I can angle the engine much further back, fixing the problem of the manifold not fitting. It was still a tight fit though so I had to do a bit of panel beating to the floor pan.

Exhaust is only temporarily fitted as I'm waiting for my heat wrap.

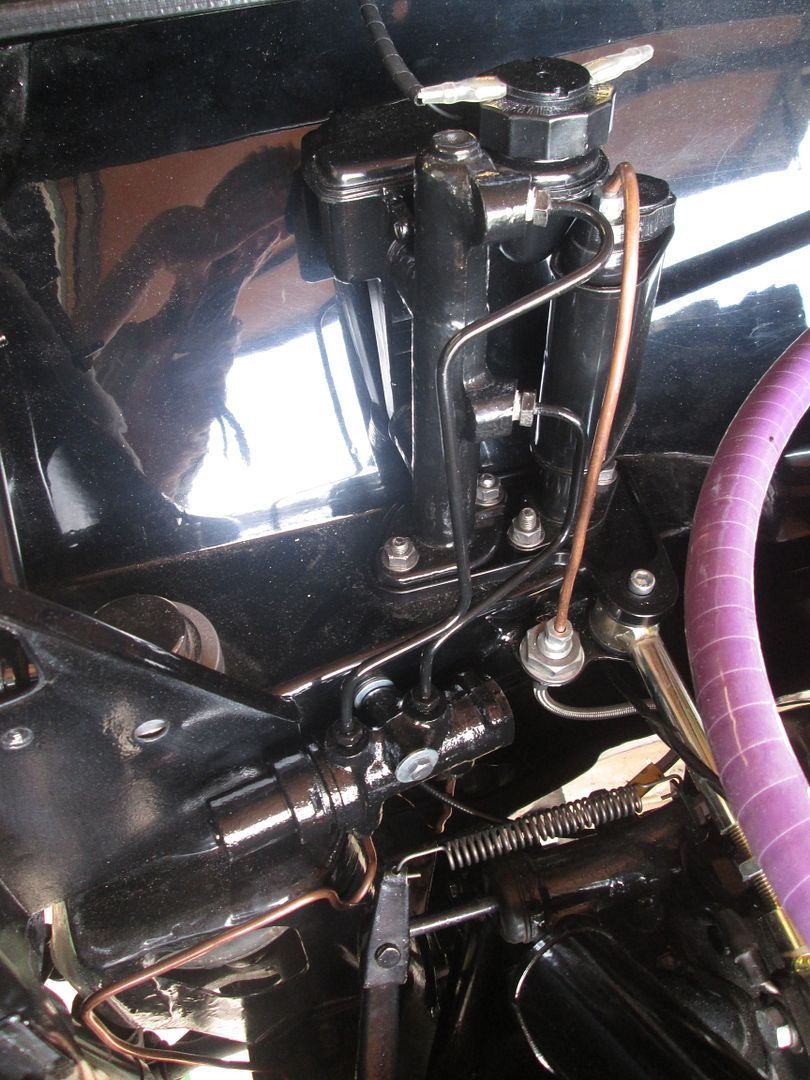

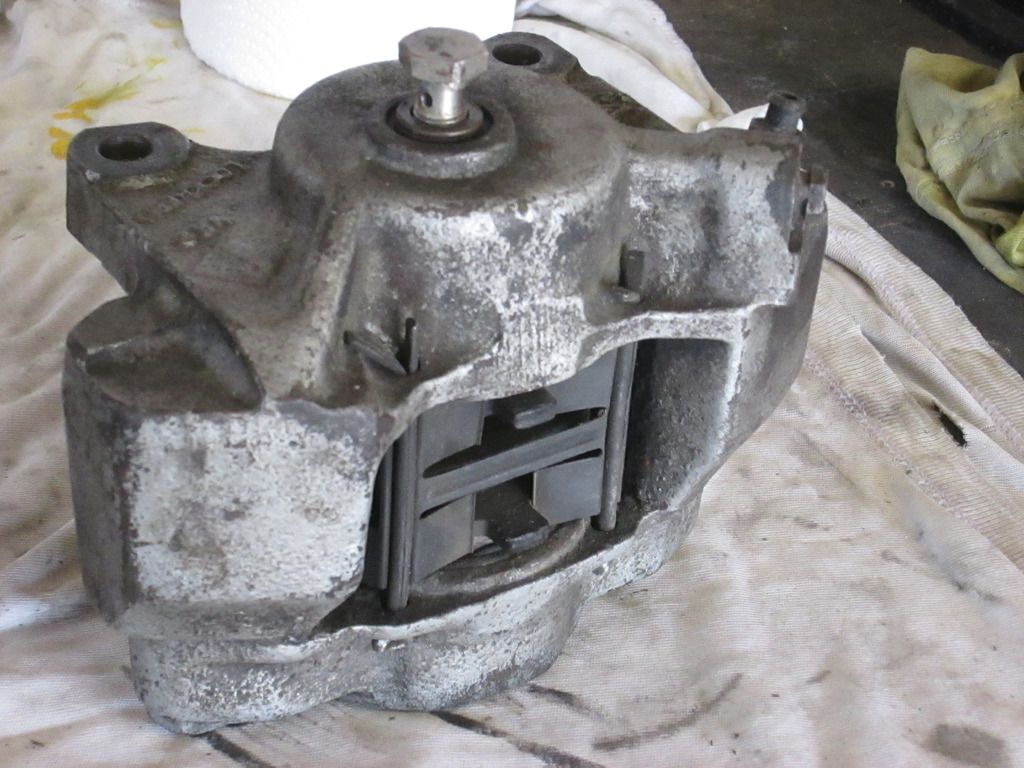

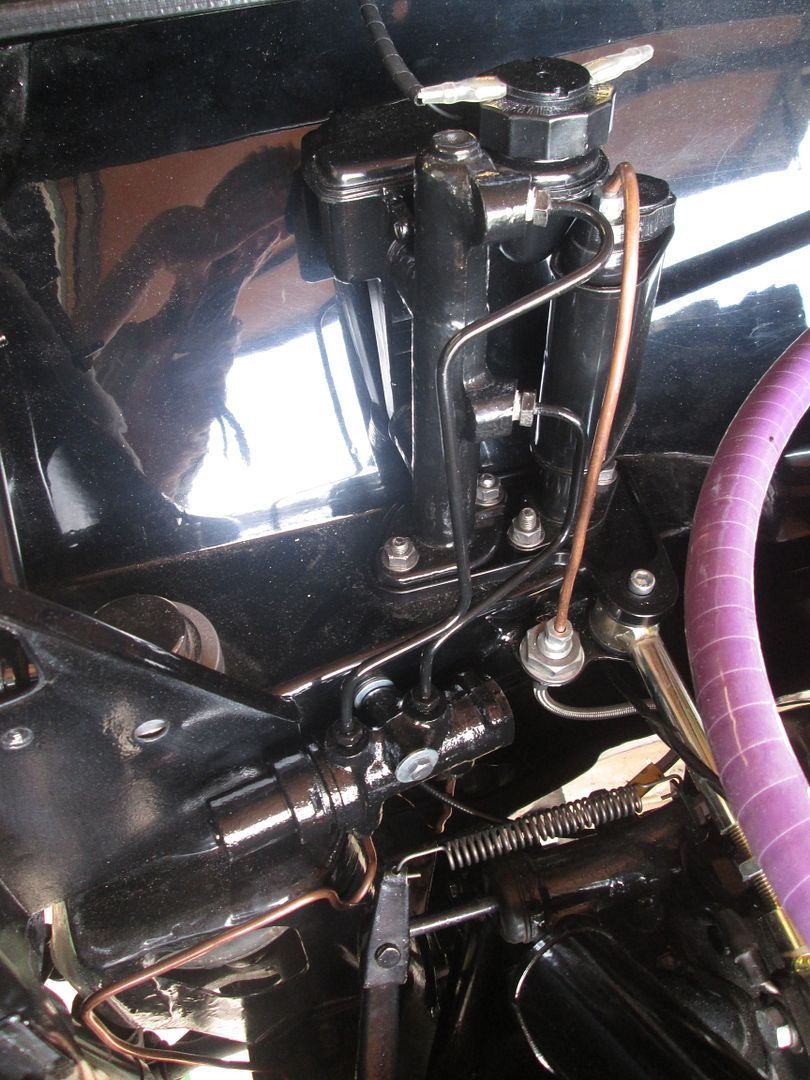

Then got all my clutch and brake cylinders fitted. I had to buy a new compensator valve due to one of the holes being completely stripped of thread which was a pain.

Next up I got the gas bonnet struts fitted. No bonnet stay for me!

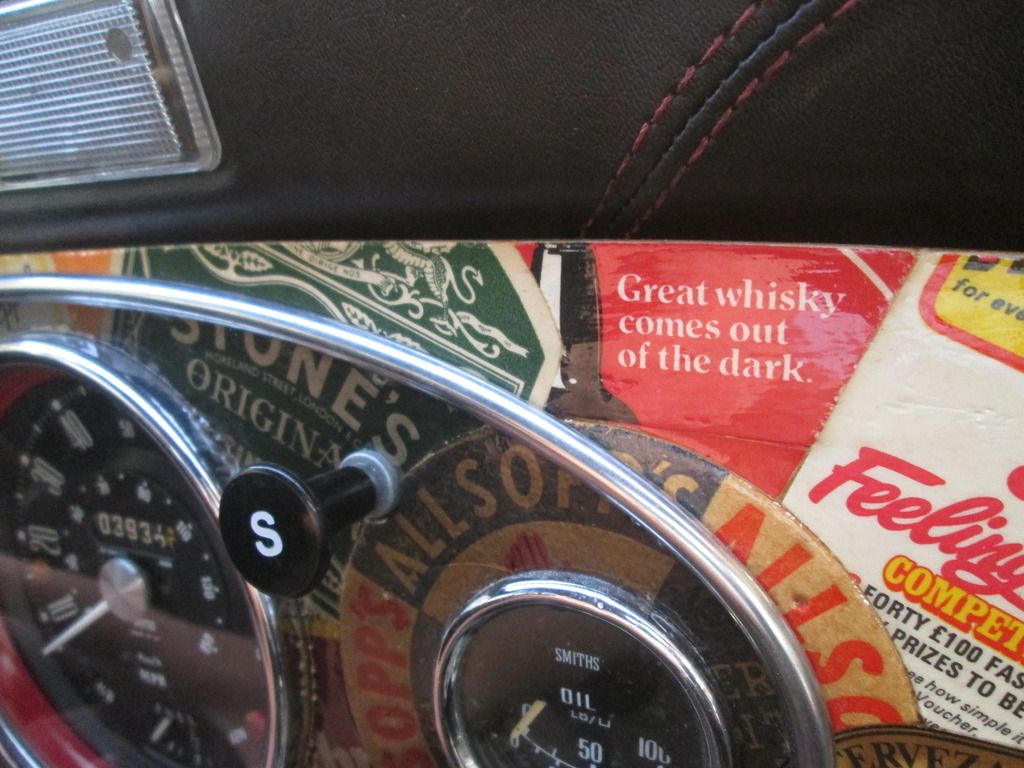

I then moved on to actually getting my custom dash to fit and be easily removable despite the roll cage being completely in the way.

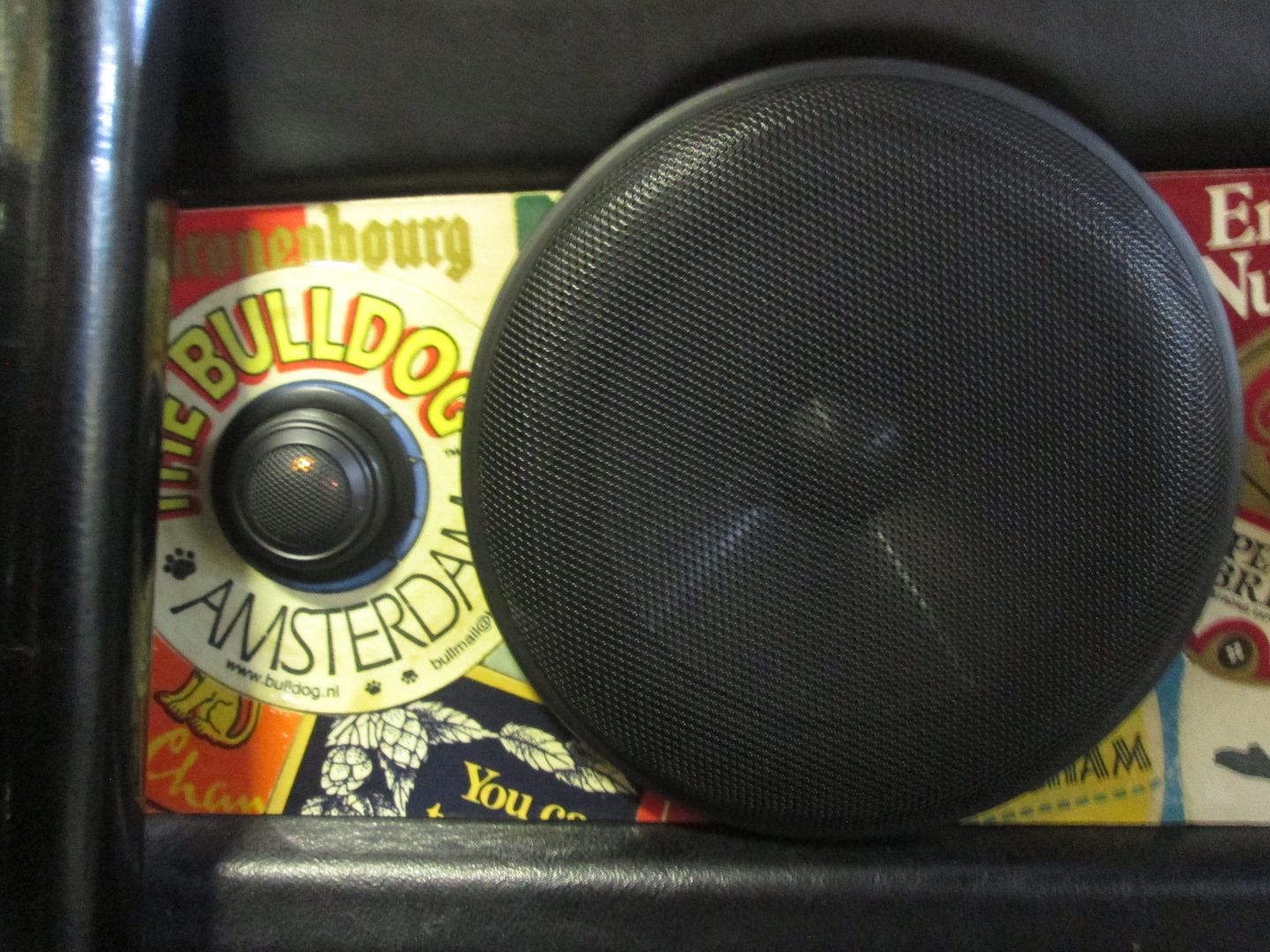

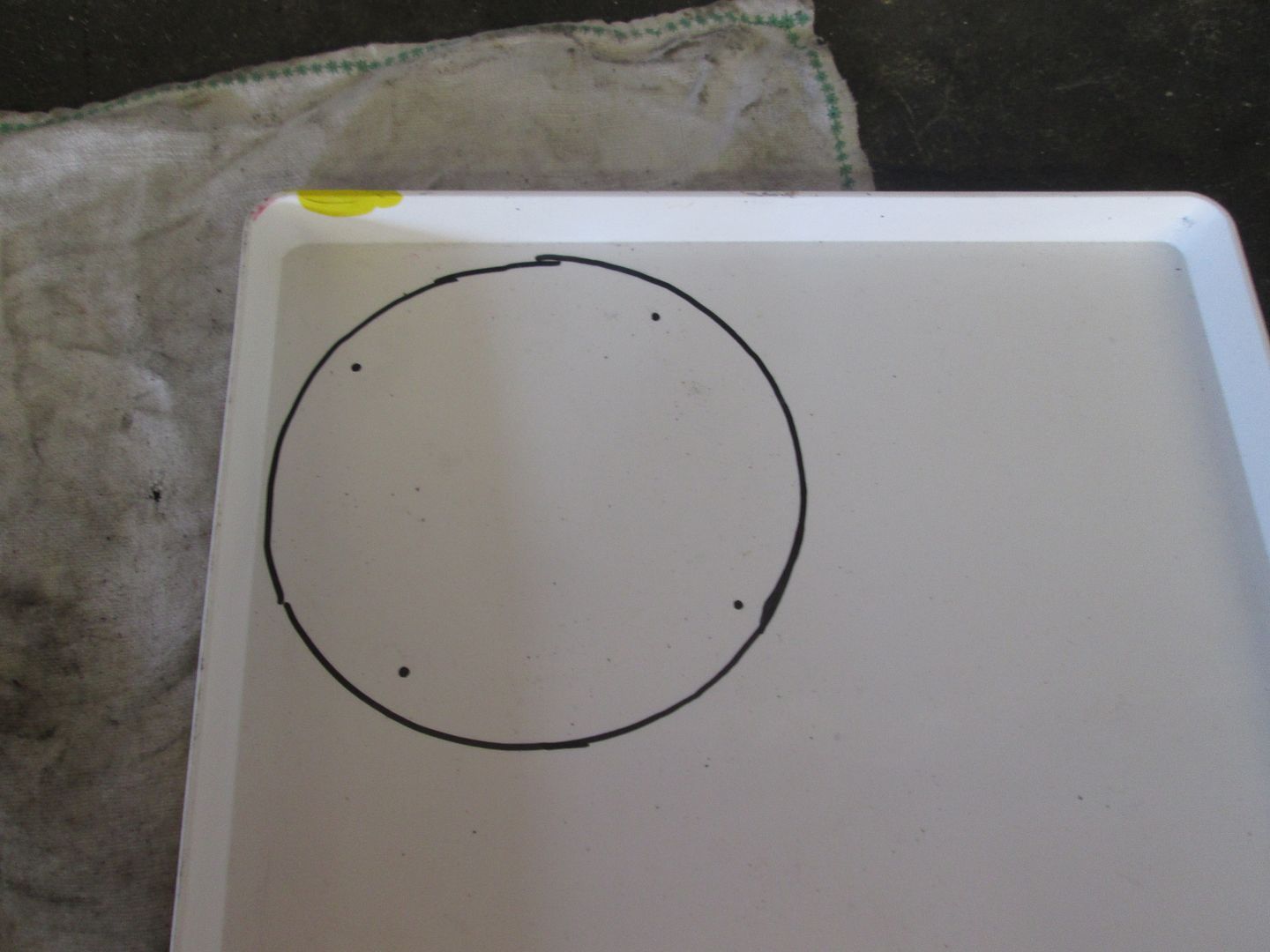

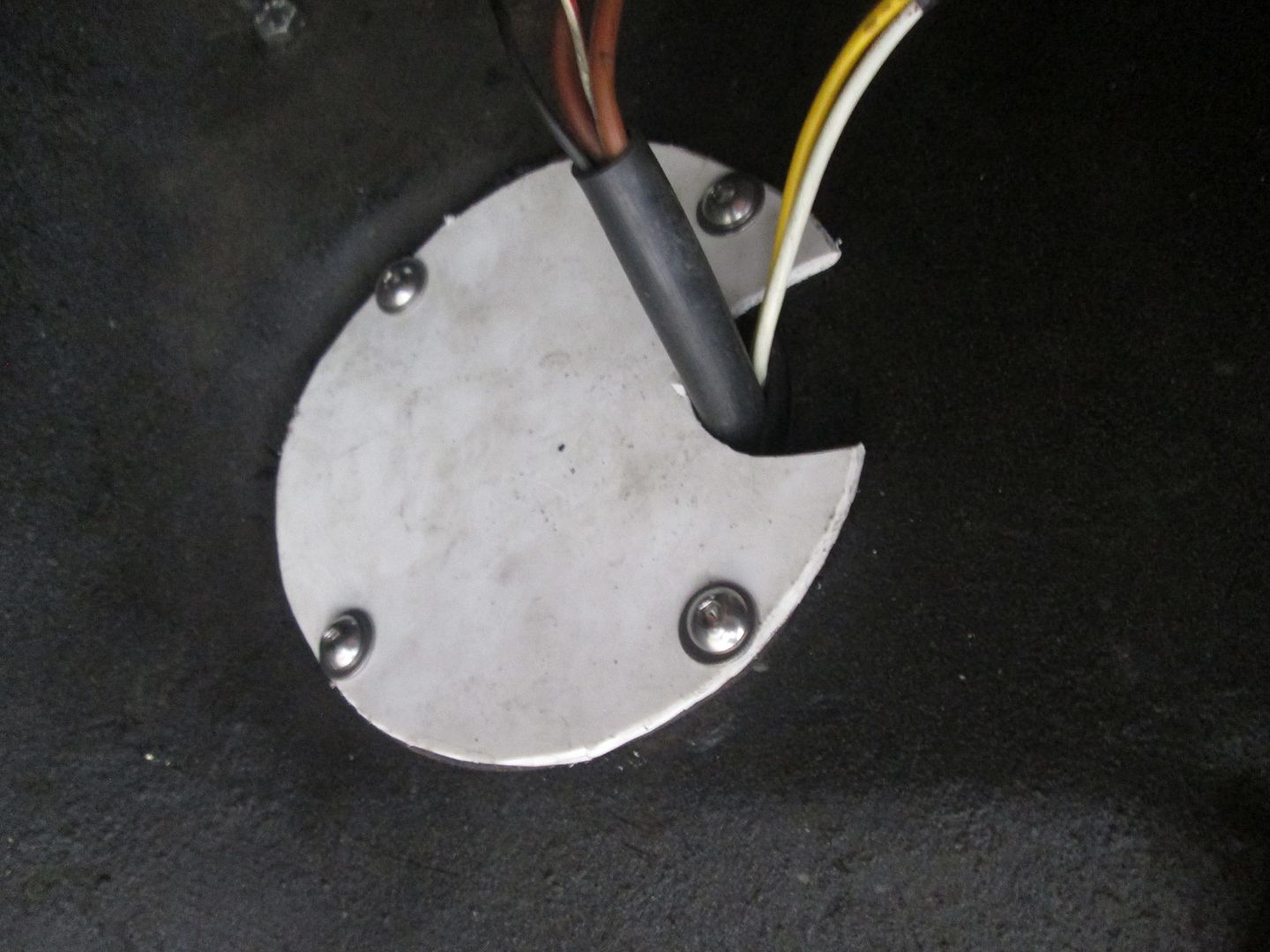

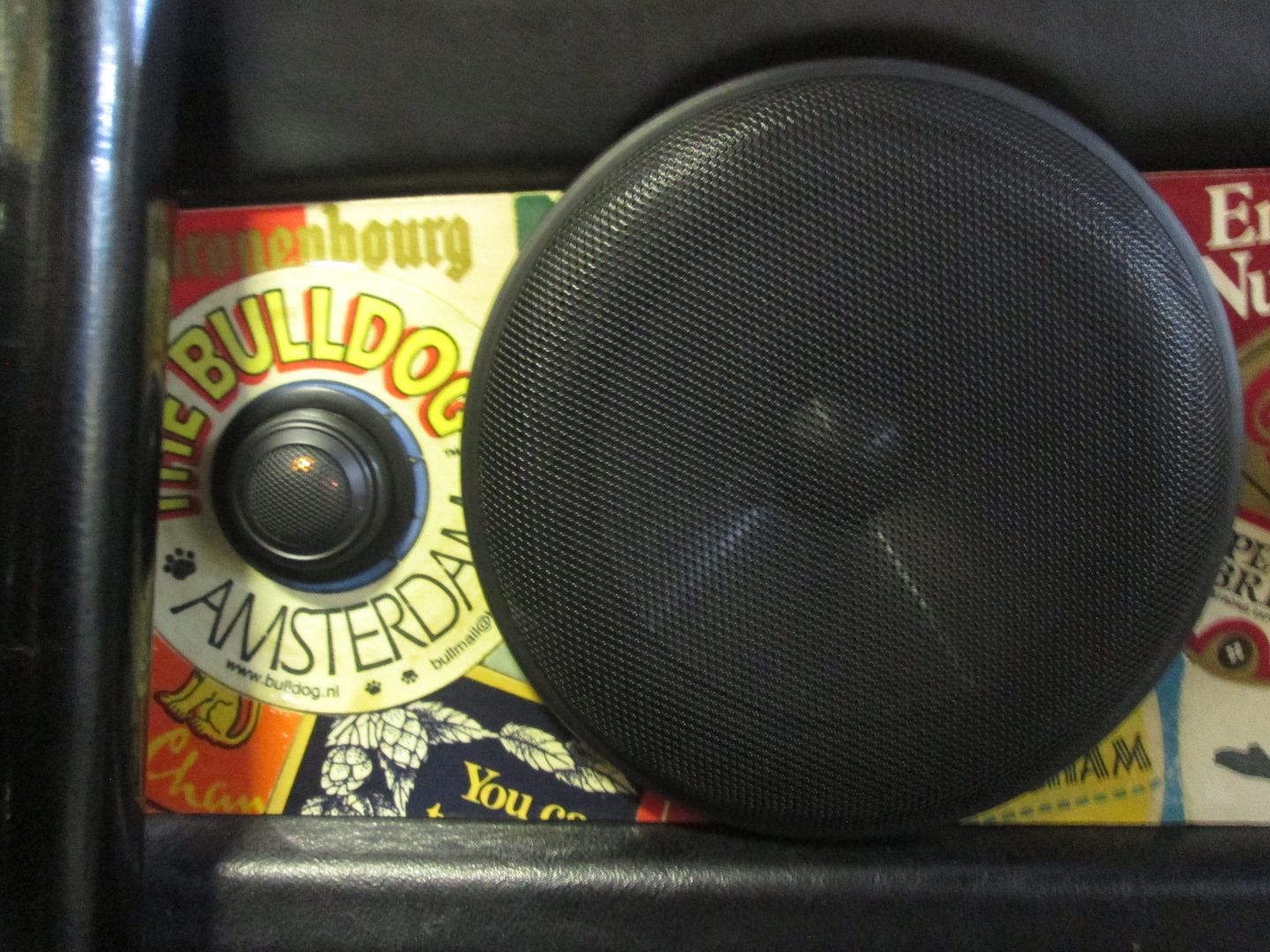

The first thing I did was split it into three sections. The middle section as far as the speakers is held in place with grille buttons and custom brackets, while the end sections are simply held in place by the screws that hold the speakers in. They can be slotted behind the roll cage and screwed in after the middle section is fitted. (the Speakers are JBL, I just bought some different covers since the ones that came with them were ugly as hell) I was skeptical of how sturdy this would be, but it's surprisingly very solid due to being wedged between the top and bottom dash rail... Oh wait, that's something else I forgot to mention... I fitted my top dash rail (better late than never!).

I'm pretty damn chuffed with it personally! Especially how the speakers fit into the cutouts in the top dash rail as I wasn't sure how that was going to turn out.

Part 2 coming up!

Edited by Chris1992, 12 October 2021 - 07:36 AM.

![]() so that should provide me with enough poke, I'm not going all out fast-road spec, but a bit of extra beef is always nice

so that should provide me with enough poke, I'm not going all out fast-road spec, but a bit of extra beef is always nice ![]()