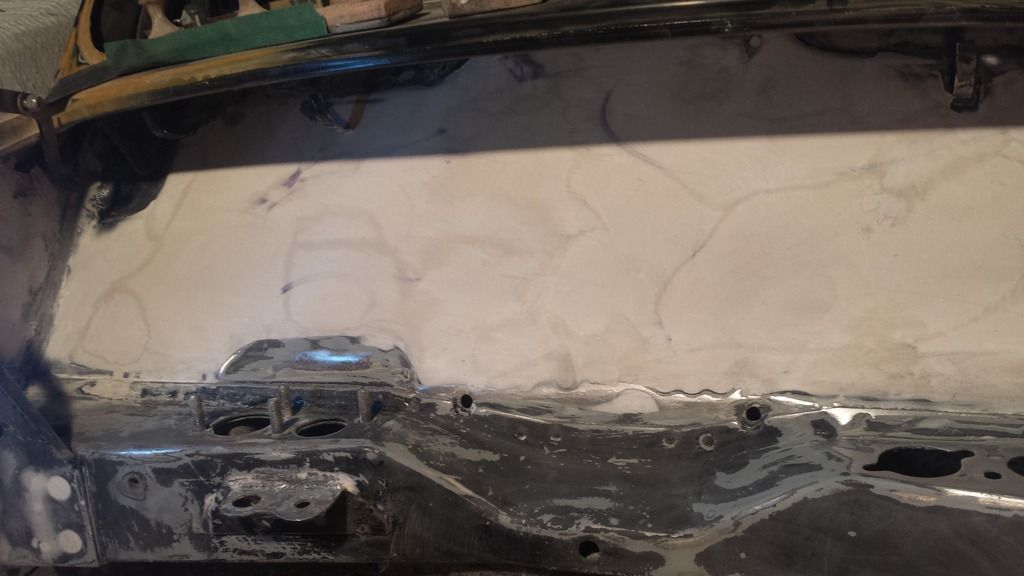

Looking good but all that filler will crack in no time i'm afraid.

I've heard mixed things to be honest

some people have said it should be fine, and others have said it'll shatter as soon as I run over a pebble... this maybe a mistake, but I'm a bit too far into it now, how much will the bulkhead flex? Will it really be enough to cause cracking? There is no filler over any panel gaps or joins, not like when I de-seamed it before, and the seams didnt crack (somehow) after a year of daily all weather use.

Maybe I'm in denial... ah well, I guess I can always vinyl wrap the bulkhead if it does crack slightly.

Not only that, but all that filler will weigh a ton. You better off getting a large steel sheet the size and shape of the bulkhead and welding it over the top of the existing bulkhead, as one large panel. Ideally it would be better to chop the bulkhead out and then weld in the panel, but plating over it would be easier, neater and take a hell of a lot less filler and tidying up after.

god damn it... I must admit, the only thing stopping me from going out there and attacking it with an angle grinder right now is thinking about how long I've spent shaping that panel (as i mentioned, its a lot further along than the pics above)

would it really add that much extra weight? keeping in mind I'm not building this thing for the track?