slacking with the updates. poor effort...

right, I'll kick things off with our new welder, or should I say jigsaw puzzle....

sorted

then decided to just dive straight in with it and weld up the hole in the bulkhead.... yeah because that went really well....

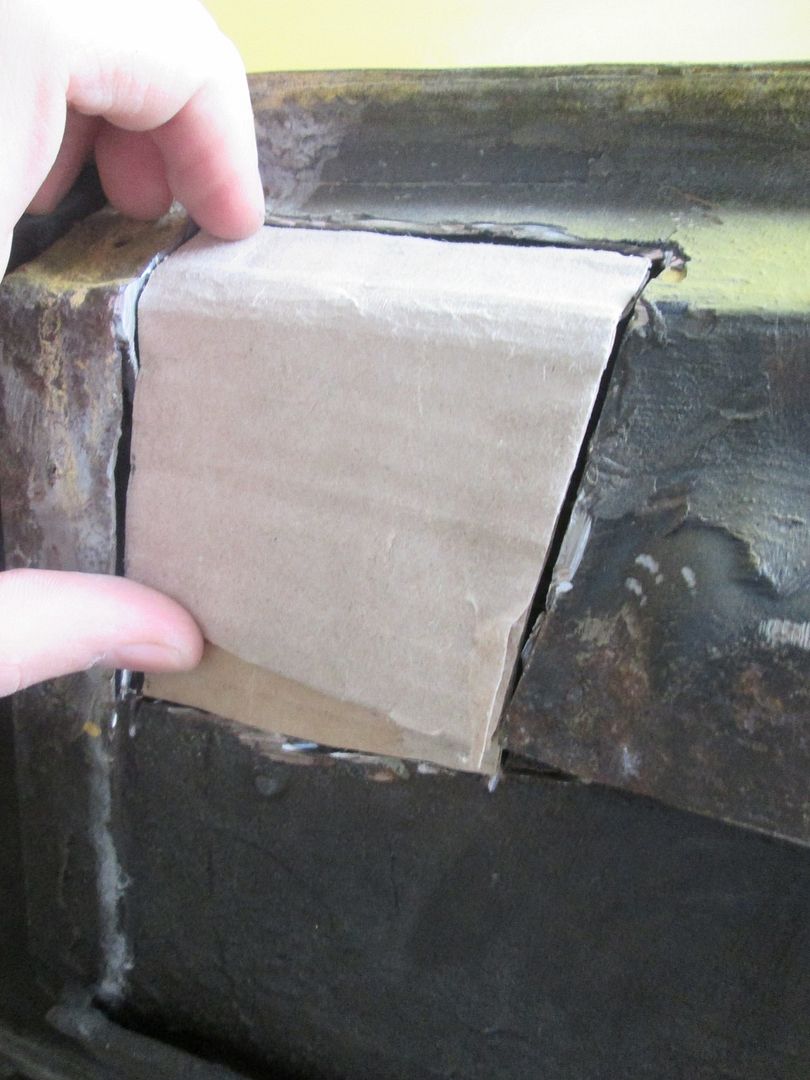

started off with a cardboard template

then made a steel patch from the template

and then successfully completed what is probably the worst welding job man has ever seen...

to all experienced fabricators reading this, i can only apologise

this was after grinding it down

ah well, the way i see its solid, and its not a structural panel so its nothing a bit of fiberglass matting behind it wont fix.

next it was time to address the big hole i made in the sill, so same process again.

cardboard templates

followed by metal patches

except this time i recruited some professional help, in the form of forum member 'Artful Dodger'.... what a lovely chap

and what a lovely job he did

and after a bit of grinding

bit of stone chip and it'll be lovely jubly

moving on from that, i then did some work on getting the grille to fit

as you can see from the pics it was a bit of a rubbish fit

so armed with some pliers, i went on a bit of a bender. (pun intended)

managed to get it to fit much better, although it needs a dash of filler now

much better

next up was the bonnet. started off by drilling out the spot welds that hold the front lip on so i could convert it to the MK1 style

bit crusty, but it cleaned up fine once i went over it with a wire brush

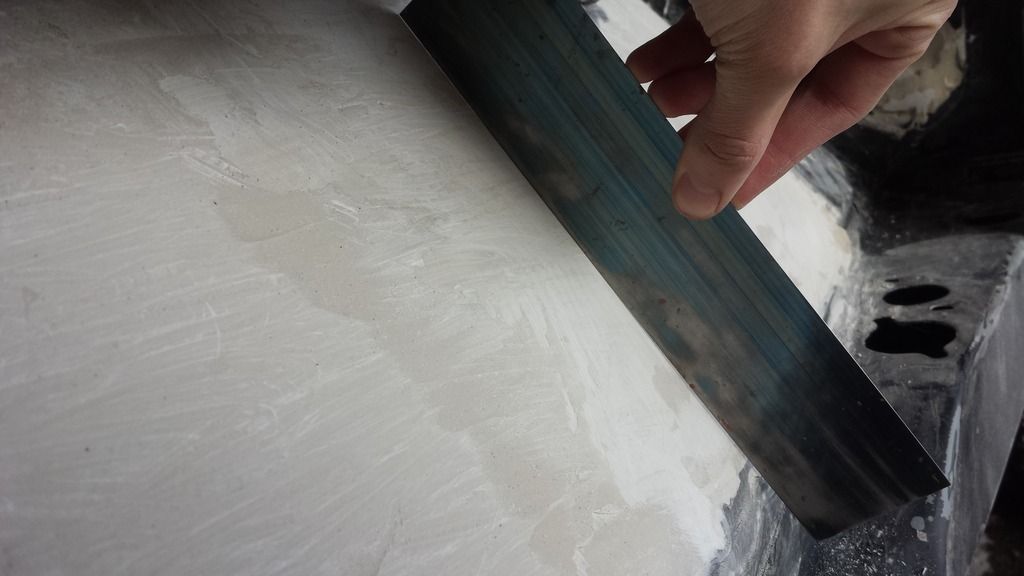

then it was time for more bodywork. initial rub down

followed by just the tiiiiiiniest amount of filler...

working my way across

not looking too bad. feels pretty flat so thats good.... back when the car was painted and shiny, the bonnet looked like had been caught in a hail storm...

then decided to get the front splitter mounted up

so out with the hack saw

rough as nails to begin with

but it got better... ish

and there you have it

couldnt resist a little mock up with the bonnet, bumper, grille, and arches

and lastly, i did a bit of fiberglass work to the arches to make them curl round the body at the front a bit better.

the arches have actually come a lot further, but didnt have any pics handy, so ill post updates on those next time