another small update today as i managed to get in the garage for a couple of hours.

I put the shell back down the right way up and started by removing the sealer from the back edge of the floor.

I prefer to burn it off so i set it on fire

And then gave it a scrape and a wire brush and that's done

I wanted to get the quarter panel off today so i though it might be a good idea to replace the waist rail first. It needed changing as there was significant rust on the top flange

First job was to mark out all of the spot welds from the inside

The reason being the spot welds are very faint on this car so hard to see from behind a face shield

So next, i drilled them

And then carefully split them. It was prudent to do this carefully as i needed to keep the top egde of the quarter panel straight and intact to line the new waist rail up to.

Once the spot welds were split, it was then just a case of bending the waist rail back and forth to break the seam weld that holds the back edge to the rear bulkhead.

here it is removed

and the new one. (well used actually)

I gave it a good look over and even though it looked great, i imagined there would be rust between the waist rail and the trim retainer so i drilled the spot welds holding it on and i wasn't wrong.

Pretty nasty but salvageable. I gave it a good clean up removing all of the rust from the pitting

zinc primed

and then clamped the two pieces back together

After welding them up and cleaning them back it looked like this

As good as a new one and didn't cost me a penny

Anyway, i clamped it onto the car using the old quarter panel to help align it

and then welded it in

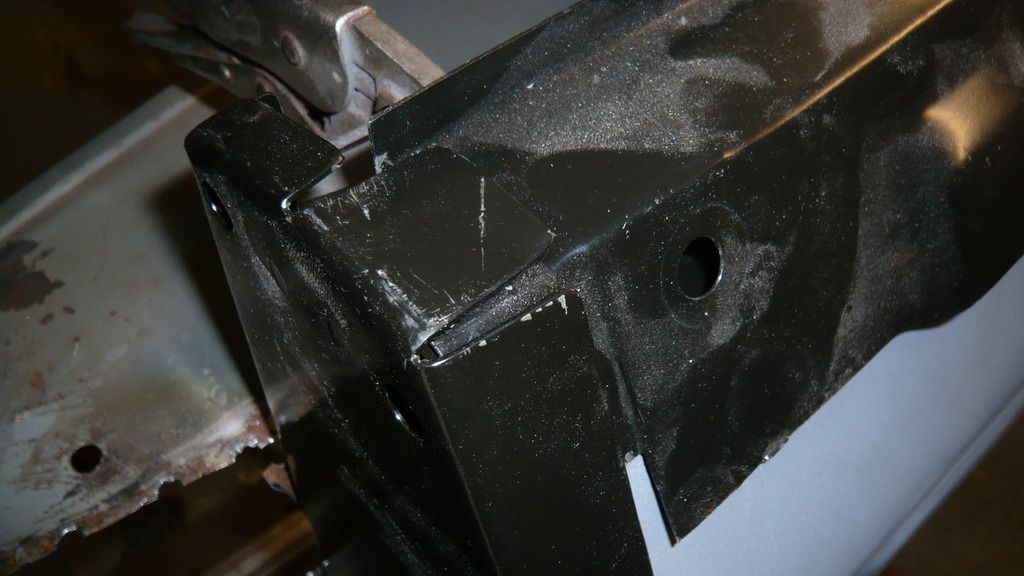

Once that was done, i finally lopped the quarter panel off

It didn't put up much of a fight but there was alot of filler down the back edge which made a mess whilst i was cutting through it.

And then i clamped the new second hand quarter on just to check it all fits. Which it does!

and that was it for today.

Cheers

Ben