A bit more done today.

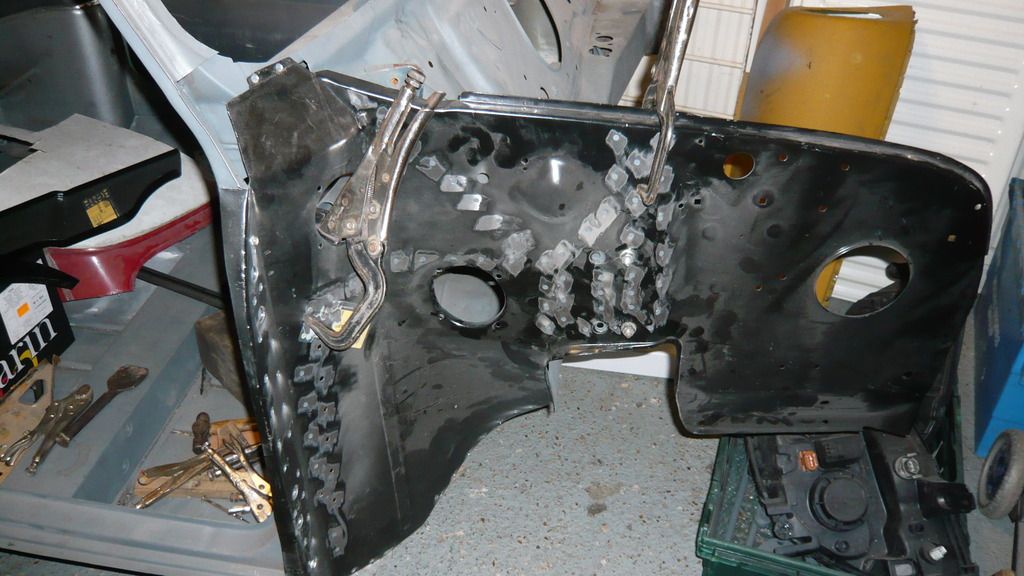

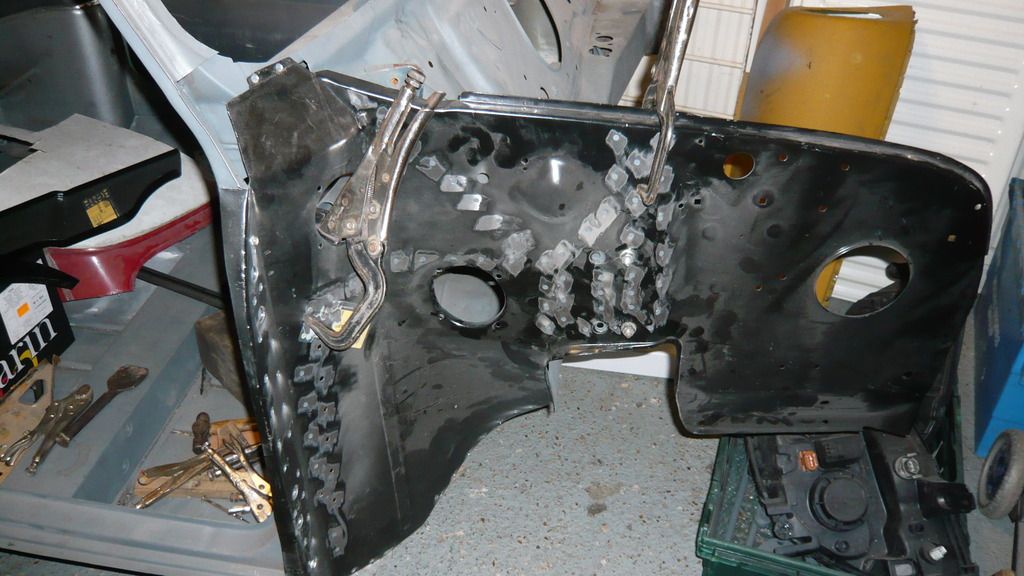

started by drilling all the holes in preparation for plug welding the inner wing on

Then i linished the burrs and removed the paint from the areas that are to be welded

And applied some Zinc primer

Here it is clamped back into position. There was no need to refit the door, Apex panel and Wing to check panel gaps as i can now position the inner wing in exactly the same place everytime i put it in so that saved some time.

The first few of many plug welds.

At this point, i only plugged up a select few of the holes to keep the inner wing into position because i had a bit of a problem to sort out.

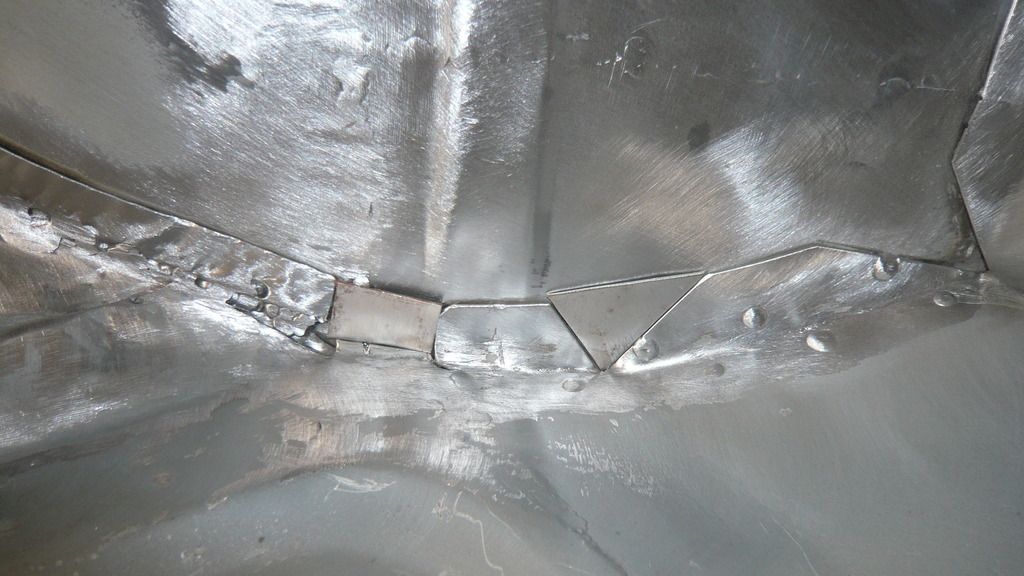

This meant tipping the shell back on it's side to reveal the problem.

It's not brilliantly clear but there is a half inch gap between the bottom of the inner wing and the floor/inner sill. The toe board fits perfectly to the inner wing and the inner wing is definitely at the correct height and fits well everywhere else so i don't know how this has happened??

My plan A was to use a block of wood and a club hammer to bring the floor down to meet it but this didn't work so i had to take Plan B

Thats right, i had to cut a lump out of my £100 panel.

anyway, needs must and all that so i repositioned it for a better fit

Then scribed it, cut it and laid it back into position

Tacked it in

And readjusted another piece which you can see towards the bottom of this picture

Then welded it up fully

And ground it back

Once it was all sorted, i ended up with an odd shaped part where it wraps under the floor so i have made up a piece to go in. Not strictly needed but i felt it would look neater

That will be welded in tomorrow along with the rest of the plug welds on the inner wing. Other than that, i need to trim the bottom of the inner wing where it meets the front of the outer sill as the profile is wrong.

Cheers

Ben