So today i managed to snag a few hours in the garage but it all started going wrong so i got the Hump and came in.

Ill show you what i have anyway.

As i still haven't got my hinge post, i thought i would have a go at some gutter repairs. Not my favourite job in the world by any stretch of the imagination and it's one i have been putting off for a long time.

I do wish i had left it now.....

Anyway, the damage

Loads of surface rust on the gutter edge and more than i am comfortable with in the seams.

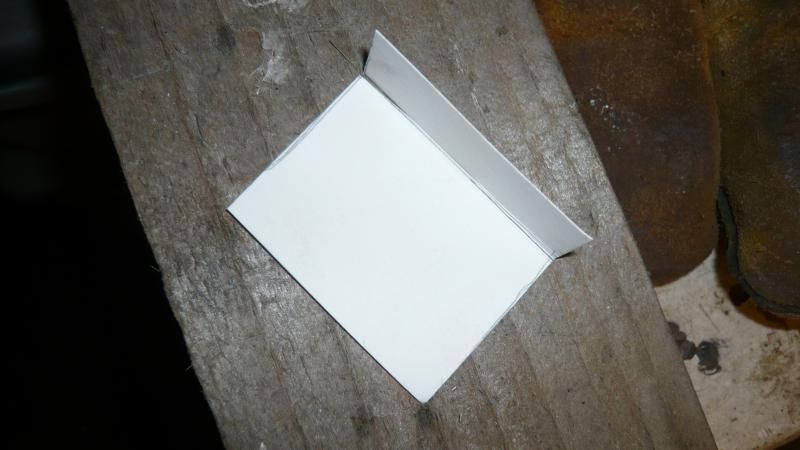

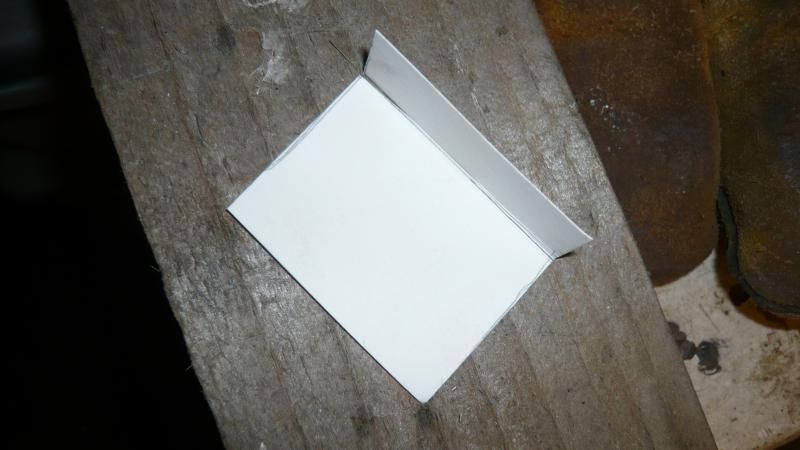

So i made up a new piece to go in there, like so

So happy with that, i marked up the bit on the car ready for cutting and started cutting it away.

There was part of the frame which was a bit pitted and thin so that went too

Needed to make up a piece to go in. That was the usual cocktail of make up a piece in car and transfer to steel

With that done, i welded it in and started to offer up the new gutter piece.

It needed some work at the front to follow the curve as it was quite a bit out

That was easily solved with some strategic slotting

Better!

So i cleaned up all of the edges ready for welding and drilled some holes in the roof skin for plug welding

And zinc primed the edges and my repair piece

Clamped it in place and tacked it but that's where it all went wrong

I forgot the most important thing when welding upside down.....

.....TURN UP THE WIRE SPEED doh!

So my tack welds kept blowing holes and leaving huge build ups of blobby molten weld

So with the Arse, i tidied up and came in. Ill deal with that mess tomorrow.

Ben

![]()