I have ordered a new grinder but can't wait till Wednesday for it to show up so i made a start today manually.

So i put the Mini back on it's side and took a look at the floor. I haven't touched the floor since the flood and to be honest, it's not too bad all things considering.

Ignore the inner sill,i just put it there to get it out of the way!

Anyway, i started by removing the battery cable retainer and the brake pipe clamps because i knew there would be rust behind and i wasn't disappointed.

Next, i removed the rear slinging bracket and part of the heel board as i need to do a repair to the floor here.

Slinging bracket lopped off the old fashioned way

Drilled the spot welds holding the heel board to the floor

and lopped that off in a similar fashion. It's amazing how much you take a grinder for granted when you have one!

That's enough out of the way for now.

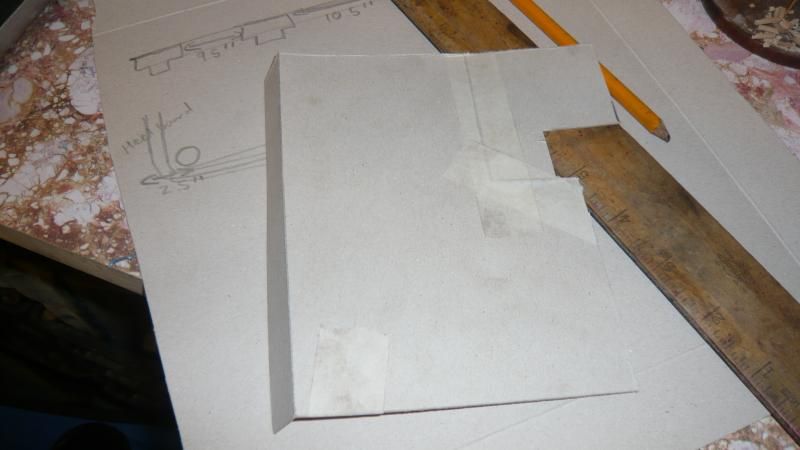

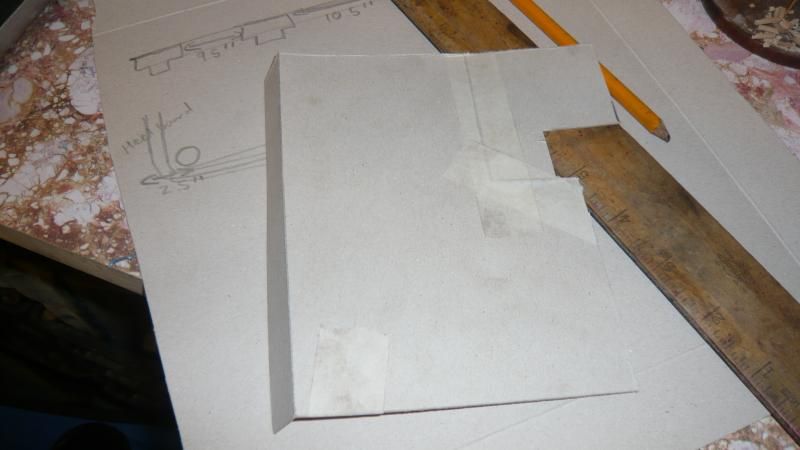

So onto making up a card template to get that floor fixed.

Nothing unusual or exciting here.

Anyway, onto steel

You will notice that i also drilled the hole for the drain plug to fit into. It was a straight forward operation of clamping the patch onto the car, clambering inside and colouring in with my felt tips from the inside to mark the holes location and then attack it with a step cutter.

And finally, try it on for size, looks ok

I have a second hand rear bin that is good along the bottom so i am going back out to dig it out and trim the bottom off of it to repair my one with, Once the grinder is here, i can cut a lovely straight line with a 1mm cutting disc and lop off the inner sill part of the new front floor and the remains of the inner sill from the rear half and start prepping for the inner sill.

It's all rather exciting!!

Comments welcome

Ben