I think the point i was edging towards is that everything works until the moment it drops on the slam panel. I'm pretty sure that the rocker shaft wouldn't appreciate the treatment either.

Seems a shame when you have a pretty little car like that not to buy a cheap pull lift - I've got a little Yale lift rated at 600Kg single sheaved that is perfect for lifting mini engines....safely. It didn't cost very much either.

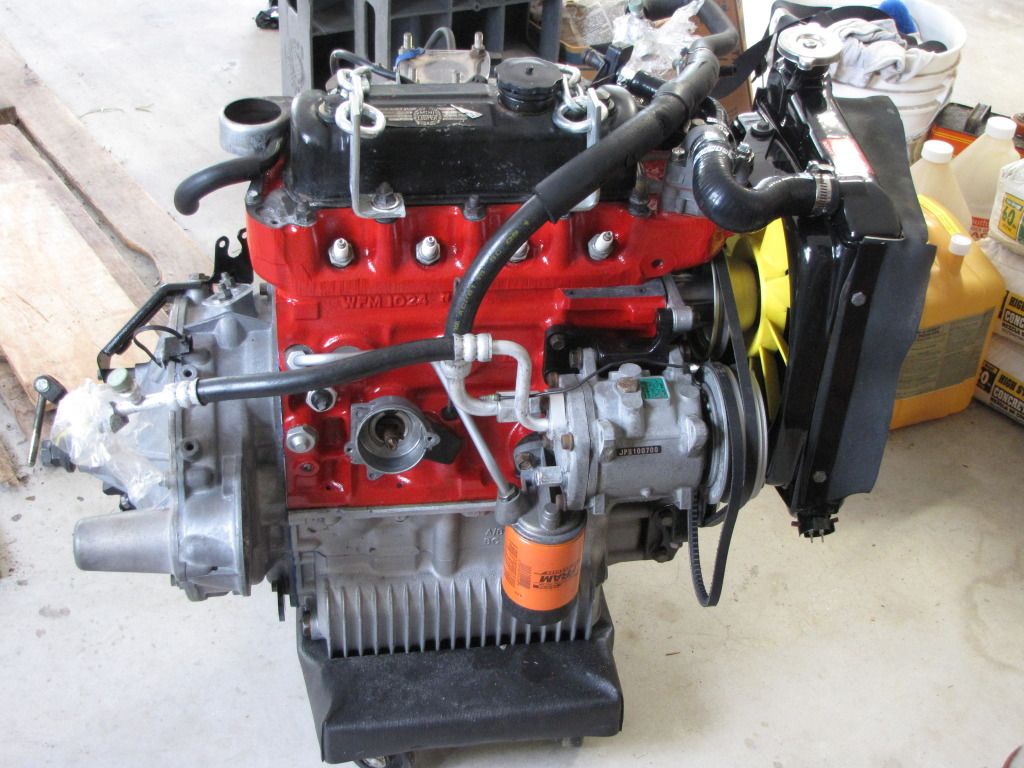

I bet you had fun getting that clear of the front panel.....

I agree about the poor rocker shaft being under excessive load.......

It is only a hollow shaft and I think you could put a set in it quite easily....