What's The Best Place To Lift The Engine In

#31

Posted 01 April 2013 - 10:50 AM

#32

Posted 26 May 2013 - 07:12 AM

Saw this on Ebay. I have never seen an engine lifted like this; I am surprised it did not strip the threads.

#33

Posted 26 May 2013 - 08:12 AM

Saw this on Ebay. I have never seen an engine lifted like this; I am surprised it did not strip the threads.

It seems like a stupid idea to advertise lifting an engine like that. It's a tiny thread, I've had one of those threads kill itself from over tightening some T bars

#34

Posted 26 May 2013 - 08:20 AM

On some older BMC cars with inline A & B series engines and plenty of room under the bonnet the factory engine lifting brackets were left in place on the rocker cover by the factory......however they were not really meant for use on the small rocker cover bolts of heavier transverse Mini engines complete with the gearbox attached, they also lift engine at the wrong angle for a Mini........a safer load and better angle of lift is achieved using the lift brackets on a couple of the front head studs instead.

http://forum.minicoo...read.php?t=7924

#35

Posted 26 May 2013 - 01:59 PM

I never said diff casing, round the part of the clutch housing where the starter motor sticks out then around the exhaust manifold this allows the engine to turn round if needed or moved from side to side as well.Good luck with the diff casing.

Something to remember before putting the engine back in hook the speedo cable on makes it allot easier than trying to fit it when the engine is in

I can't say I'd lift it by the manifold - just look at the cantilevered loads on the studs.

To be honest I find it much easier to lift the body off, but each to their own.

If I was lifting it would be by two head bolts - engine can't topple as it could if lifted from a point lower down.

#36

Posted 26 May 2013 - 02:00 PM

Saw this on Ebay. I have never seen an engine lifted like this; I am surprised it did not strip the threads.

It seems like a stupid idea to advertise lifting an engine like that. It's a tiny thread, I've had one of those threads kill itself from over tightening some T bars

Agree - it's been subject of warnings for about 40 years - those bolts aren't strong enough.

#37

Posted 26 May 2013 - 02:04 PM

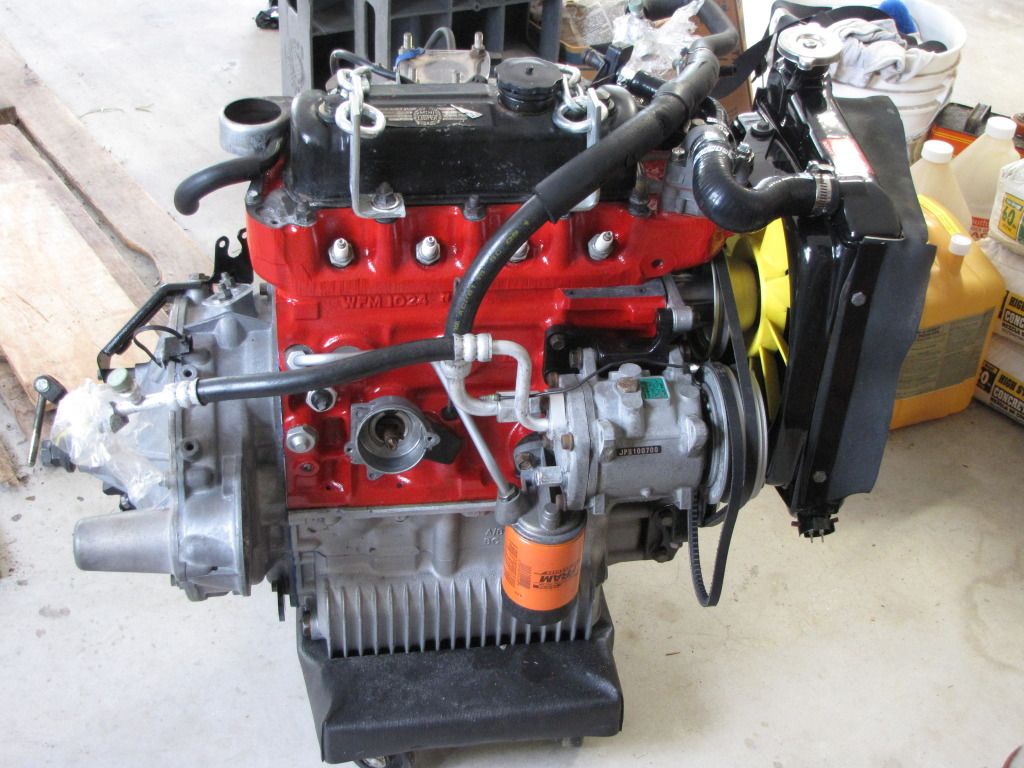

Mine came out like this:

And went back in like this:

How did you clean up your AC compressor? Mine needs a spruce up.

#38

Posted 26 May 2013 - 02:05 PM

I've got a Pierre Cardin luggage strap that looks just the same as that. I never knew they were tagged as lifting straps too ![]()

#39

Posted 26 May 2013 - 02:52 PM

Mine came out like this:

And went back in like this:How did you clean up your AC compressor? Mine needs a spruce up.

I used this stuff on all the aluminium parts (except the gearbox from Guess-works) with a brass wire brush:

http://www.loctitepr...minum-Jelly.htm

Edited by xrocketengineer, 26 May 2013 - 02:54 PM.

#40

Posted 26 May 2013 - 11:12 PM

Thanks! Another quick question - I see that you've disconnected your AC pipes from the evaporator, where is the connection? is it inside the car under the bulkhead?

Thanks again.

Edited by Captain Mainwaring, 26 May 2013 - 11:12 PM.

#41

Posted 27 May 2013 - 01:17 PM

It is by the bulkhead in front of the wiper motor and covered in black sealant. It is right behind the orange tape next to the low pressure service fitting in the next picture:

It is clearly visible in the second picture between the two yellow relays and the inertia switch:

Edited by xrocketengineer, 27 May 2013 - 01:19 PM.

#42

Posted 27 May 2013 - 01:44 PM

I've got a Pierre Cardin luggage strap that looks just the same as that. I never knew they were tagged as lifting straps too

it is indeed a luggage strap, not too sure about it being a pierre cardin one though

but it worked ;)

#43

Posted 27 May 2013 - 10:59 PM

I think the point i was edging towards is that everything works until the moment it drops on the slam panel. I'm pretty sure that the rocker shaft wouldn't appreciate the treatment either.

Seems a shame when you have a pretty little car like that not to buy a cheap pull lift - I've got a little Yale lift rated at 600Kg single sheaved that is perfect for lifting mini engines....safely. It didn't cost very much either.

I bet you had fun getting that clear of the front panel.....

#44

Posted 27 May 2013 - 11:03 PM

I think the point i was edging towards is that everything works until the moment it drops on the slam panel. I'm pretty sure that the rocker shaft wouldn't appreciate the treatment either.

Seems a shame when you have a pretty little car like that not to buy a cheap pull lift - I've got a little Yale lift rated at 600Kg single sheaved that is perfect for lifting mini engines....safely. It didn't cost very much either.

I bet you had fun getting that clear of the front panel.....

I agree about the poor rocker shaft being under excessive load....... ![]()

#45

Posted 27 May 2013 - 11:04 PM

Thanks - I'll have a look in a minute - I could have sworn mine was continuous so dropped the pipes at the compressor and plugged them - The unions must be mumified under Rover's black gunge.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users