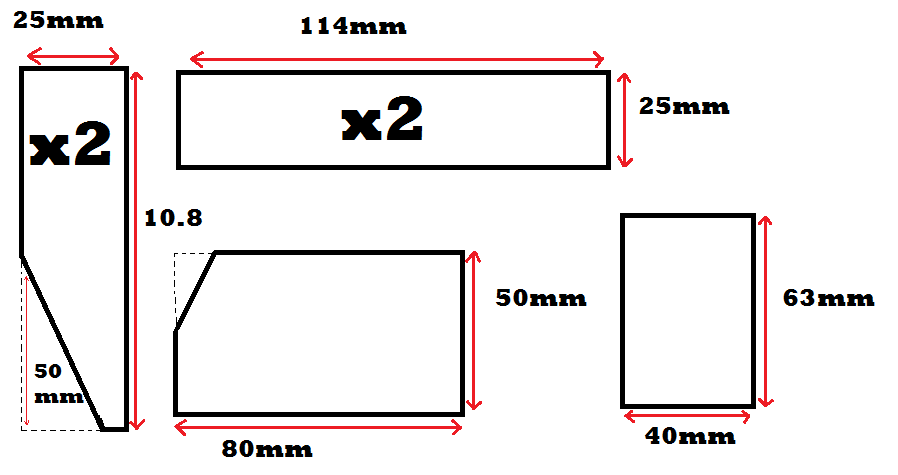

To make 4 Extended seat brackets (2 for each seat) we used, about 2 meters of 3mm x 25mm and about 0.25 meters of *3mm x 80mm* steel.

The original brackets are needed to get the holes in the right places, and the distance between the 2 uprights.

The 40mm peice is an 80mm peice cut in half.

These are the measurements I used, but i would double check against your cross member to make sure,This make's one bracket.

Once these are cut out:

First off I welded 2 peices of metal to the angle of the cross member.

I Filed the edges of the 2 25mm wide peices that are going to be welded so that when the two are put together it makes a "v" shape so you get better penetration, then welded them together using the angle gauge made.

grind down the welds and curve the tops.

Drill holes about 20mm from eachother by clamping the 2 together.

With the original bracket mark and drill holes for the bolts. Like above ^^

Then weld it together, again checking where the holes are and where the right angle peice goes.

Then weld in a small peice of metal between to strengthen it.

Drill 2 holes in the 40mm peice of metal to secure it to the rear of the cross member (we are going to use Rivnuts) then Bend it 90 degrees (like below vv). and weld it on, so then when it's welded fits over the cross section.

This is all the peices.

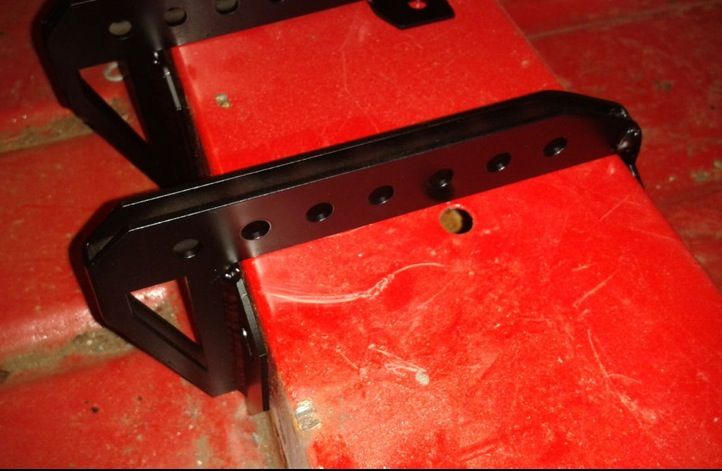

All finished, just needs a lick of paint.

How far it's moved back. It will not move any further back as the seat hits the rear bin. The second hole on the ones I fabricated is the last hole of the original bracket. giving an extra 2.5 inches of movement

You may have to move the seat catch rails as the seat catch is to far back, I would drill one hole so that you can bolt it in two positions, where the last red dot is (below). For the catch rail's put a bolt in the spare hole so if need be the bar can be moved into both positions still.

It's a lot more difficult to explain than to do, If you need any help just ask.

Hope this helps.

Alex

Edited by alex-95, 02 February 2013 - 09:31 AM.