Has Anybody Had A Go At Carbon Skinning

#16

Posted 01 January 2013 - 04:37 PM

Good Luck

#17

Posted 01 January 2013 - 05:41 PM

#18

Posted 01 January 2013 - 05:50 PM

#19

Posted 01 January 2013 - 06:02 PM

#20

Posted 01 January 2013 - 06:23 PM

It may seem daunting, but its really not. Just start with a very simple part first to get the hang of it.

#21

Posted 01 January 2013 - 06:45 PM

#22

Posted 02 January 2013 - 10:09 PM

I've covered a lot of parts and made a couple of molded parts with carbon fibers. Carbon Mods tutorials are helpfull but don't buy their kits, it's way too expensive and you will not have enough quantity to make some test and trial on other parts. Buy some fiber and resin on Ebay or at a local fiber glass specialist. My only hint for lyering is "don't let that stuff cure withou keeping an eye at it" Because it' stiffer than fiberglass, it tends to take off in concave curves.

My Group5 (CF skinning)

Miglia (Carbon Kevlar Skinning)

Edited by station wagon, 02 January 2013 - 10:19 PM.

#23

Posted 03 January 2013 - 06:56 PM

#24

Posted 04 January 2013 - 02:42 AM

Any chance of some links so I get the right stuff cheers

Sorry i don't think i would be good help on distributors for you cause i live in Canada...

I've ordered good quality resin from Fiberglass Supply in the States a few times and got a nice service.

#25

Posted 04 January 2013 - 07:55 PM

#26

Posted 04 January 2013 - 09:05 PM

#27

Posted 04 January 2013 - 10:52 PM

In my opinion epoxy is best for the skinning process, but the polyester is better if you are producing parts from a mould because of cost.

There is also acrylic resin if you want to explore all the possibilities!!!

Andy

#28

Posted 04 January 2013 - 11:40 PM

#29

Posted 17 January 2014 - 06:03 PM

I know this is an old thread now so I hope nobody minds me reviving it.

Just wondered how you got on with the carbon skinning clivemk1mini?

My dad actually stumbled onto this thread as he has been doing lots of carbon skinning on his MINI (BMW R56 sorry to the haters). he went through lots of trial and error but has got it looking perfect now and has even started experimenting with some candy coloured carbon. Hope you find it useful and if your still interested and need some advice or some parts skinning send me a PM.

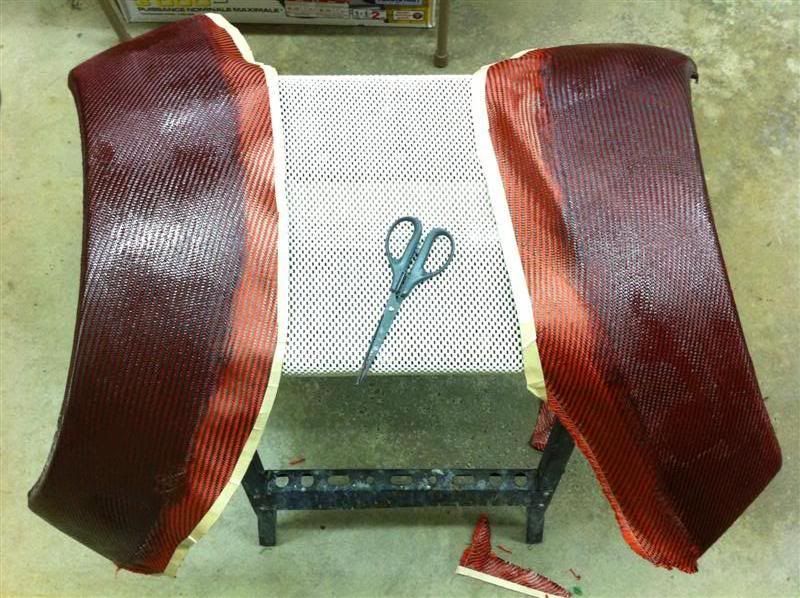

Here are some pictures.

Red Candy

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users