Mini Cooper 998 Screamer Nut And Bolt Rebuild

#1156

Posted 19 December 2015 - 09:14 AM

#1157

Posted 21 December 2015 - 06:38 AM

I used PROXL Etch primer (aerosol) followed by 4 coats of 2 pack red. Engine temps don't get that hot, the same goes for rocker covers. A normal bodywork paint will withstand the heat.

Pete

#1158

Posted 21 December 2015 - 07:21 AM

#1159

Posted 21 December 2015 - 06:59 PM

This is coming on leaps and bounds, a real inspiration!

#1160

Posted 26 December 2015 - 09:02 PM

Thank you it's good to know that I will be able to paint the engine what ever colour I want then since I can use regular bodywork paint

No prob. The only issue I can see is heat soak from the manifold blistering the paint down the back of the block when the car is stopped. This would be more of an issue with an LCB but since I'm going to wrap it, I don't think its a problem

This is coming on leaps and bounds, a real inspiration!

Thanks but still a long way to go.

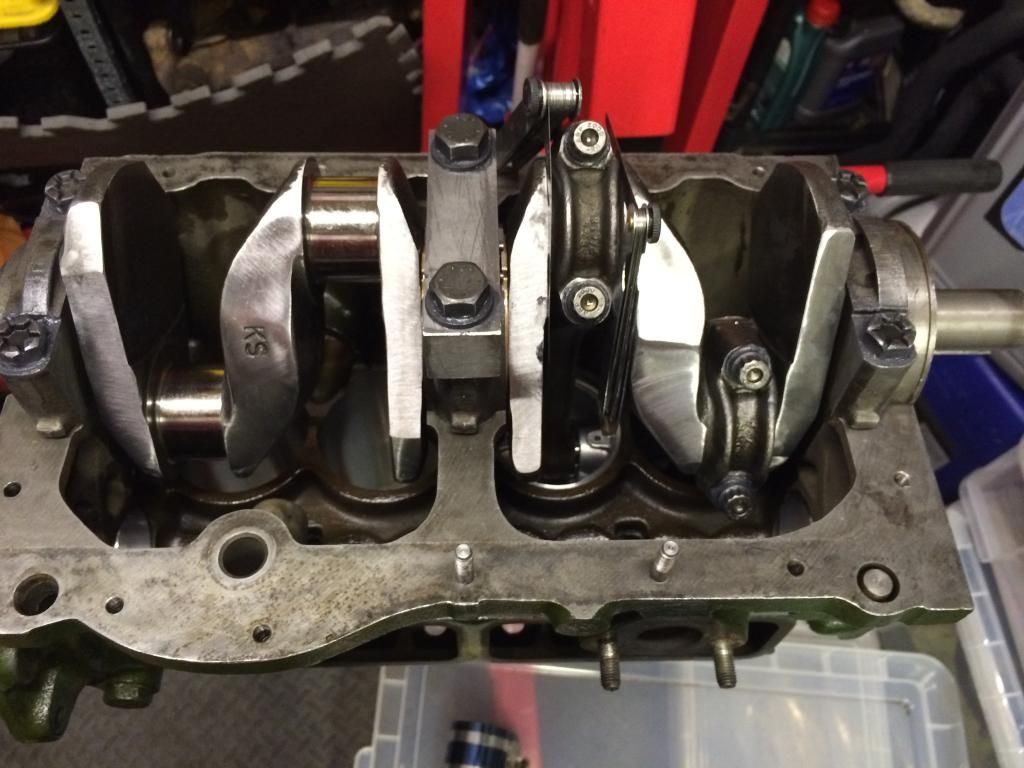

I have cleaned the block and crank, fitted the main shells then applied graphogen. I normally use oil on assembly but since the engine will be stood for some time, this stuff won't run out

Crank fitted which turns easily and smoothly

I'm going to borrow a DTI to finally measure the end float on the crank but a quick check with feeler gauges shows it's too big

I've ordered some oversize thrust washers to sort it.

#1161

Posted 03 January 2016 - 09:09 PM

I'm up to date! No more binge reading!

Amazing project! Attention to detail is phenomenal, keep at it!

#1162

Posted 05 January 2016 - 10:51 PM

Thanks for the kind words, I've still a long way to go but just want to get things as good as I can now I've come this far.

I used standard size thrust washers on one side of the crank and oversized on the other to give an end float of 3 thou. This is the proper way to measure end float. A DTI on a magnetic base.

3 thou may sound a lot but you need to run slightly bigger tolerances on a high revving engine. The same goes with the main and BE bearings. It's important to get enough oil flowing through to prevent overheating and bearing grab. An old skool grade of oil will both lubricate the gearbox properly (modern stuff is too thin) and take care of the extra thou of clearances in the bearings.

Plastigage on BE journal

2 thou, spot on

Oil cleaned off and graphogen applied

Crank rotated to fit the rod

Pistons and rods fitted.

Top of block.

Pete

#1163

Posted 05 January 2016 - 11:27 PM

Well done Pete

#1164

Posted 06 January 2016 - 11:20 PM

Just a thought.

#1165

Posted 07 January 2016 - 11:02 PM

Great detail.

Well done Pete

Thanks

Pete, have you considered arp rod bolts? They are not that expensive, also you can then bin those lock tabs as the arp bolts come with washers. I read loads of info about the locking tabs being made of "stuff" that is considered too soft, how true it is I don't know. I went for the arp bolts, instead of worrying about it.

Just a thought.

Thanks for the heads up. I haven't torqued up the big end bearings or as can be seen in the pic, knocked the tab washers over. These tabs are made from very soft mild steel, compress with high revs and can lose tension. I'm going to have a think about it and take some advice ![]()

Pete

#1166

Posted 08 January 2016 - 12:25 PM

[/URL]

[/URL]

#1167

Posted 15 January 2016 - 09:47 PM

Great idea with the feeler gauges, thanks for sharing ![]() That crank looks a piece of kit

That crank looks a piece of kit ![]()

#1168

Posted 08 February 2016 - 10:21 PM

#1169

Posted 11 February 2016 - 08:10 PM

Any progress? It's nearly been a whole month. Its not like you... Haha

Sorry no, I'm waiting for an update on the windscreen plus one or two other items from the same supplier that need looking in to. In the meantime, got stuck into the 200SX

Never a dull moment ![]()

Pete

#1170

Posted 19 April 2016 - 04:16 AM

Any up dates Pete?

3 user(s) are reading this topic

0 members, 3 guests, 0 anonymous users