Totally agree about waxoyl. I hate the stuff personally.

Bit more info on waxoyl. I posted this on another forum some time ago and have copied and pasted into here.I hope this info is useful,

Pete

I thought long and hard about the products I used on this project. I have been working on it for over 12 Months now and didn’t want to compromise on finish or protection knowing the massive effort that was going into it. I have read mixed reports about Por 15. There are some interesting reads on Pistonheads. Maybe the metal wasn’t prepped properly but some have had problems. The best primer is 2K but you have to guarantee there is no rust whatsoever. A 2K product will offer much more mechanical protection than a 1K product. The thing is, you can’t guarantee there are no microscopic rust particles even after shotblasting or wire brushing. When shotblasting for example, there’s rust dust in the air and this can deposit on the part. On the other hand if you use a 2K primer and 2K gloss and the paint chips to bare metal, the 2K primer offers no corrosion resistance whatsoever.

For me the best option was the Electrox primer, yes it’s not as hard as 2K primer but if there’s any microscopic rust particles, the Electrox primer will sacrifice itself to stop the corrosion. Applying 2K paint over the Electrox gives the best mechanical protection and if it does chip to bare metal, the Electrox will prevent the rust spreading.

It’s not easy to understand and I wish I could explain it better. Best analogy is plastic coating, if that chips things look OK until you see a slight rust spot. The rust will have travelled right under the coating.

As far as box section wax goes, I have had disappointing results from Waxoyl over the years. So much so I have decided it can accelerate rust. There are too many problems with it – you can’t get a good finish so it holds water; that’s the last thing you want in box sections with little ventilation. It’s a recipe for very humid environment. It also seems to hold water by surface tension.

To be honest the box section wax was so important on this project I decided to do a back to back test between Waxoyl and Dynax. The last thing I wanted was to spray inside of box sections with something that would do more harm than good. After all, it’s irreversible.

Started the test with 2 plates of very slightly corroded steel

Dynax on the left - Waxoyl on the right. I tried to get a good finish with the waxoyl but failed as you can see. It's also interesting to note that when I moved the 2 sample pieces, my thumbprint remained on the waxoyl but the Dynax was thin enough to cover the area.

Surface tension holding water on the waxoyl plate the morning after. It didn’t rain overnight

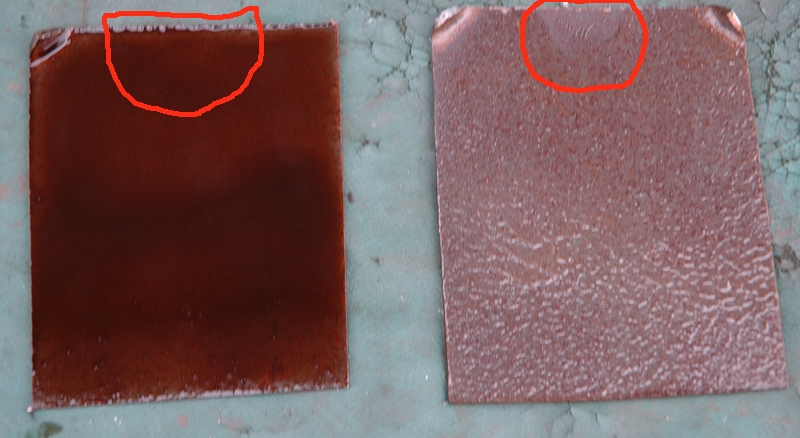

The plates a month later after spraying with a salt solution

After 6 weeks and the wax removed with solvent, Dynax on the left

Pics say it all.