[quote name="Petrol" post="2931207" timestamp="1384124559"][quote name="Dickyp" post="2930244" timestamp="1384018387"]

Have you guys looked at the Teroson stuff? I used to work for them and they have supplied the cavity wax, underbody stone guard and seam sealer to VW group for decades. Good range but I guess you would think I'd say that!!

They also a phosphate wipe so you can do localised panel prep, these are used for when panels are repaired and go through ecoat.

Keep it up as you are tempting me further to make a purchase!!!

[/quote]

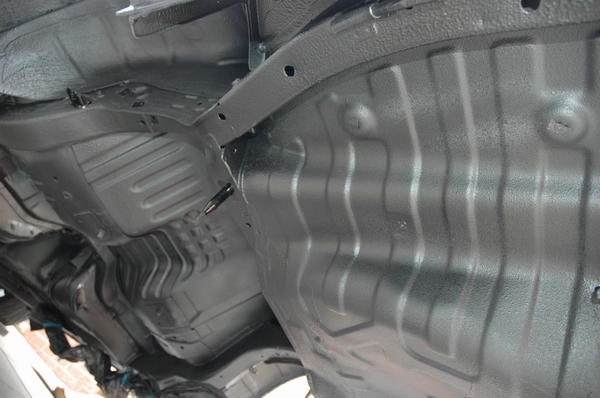

Thanks Dickyp, I have never heard of the Teroson stuff but have had a look into it. Part of the Loctite group, a name that we are all familiar with. It looks like good stuff and if VW are using it, it will be a top notch product. Looking at this MPI shell, it seems to me that there are 2 main reasons why it's so bad - Lack of protection inside of the seams and a severe lack of coating underneath. By filling all of the seams with zinc, proper seam sealing and spraying the whole shell in 2K paint before I even start with stonechip / box section wax, it should last. I guess only time will tell.

I cant say I have used the 3m stonechip. Only gravitex. I am yet to buy stonechip for my mini so interested to see how this stuff lies. I have never personally had issues with adhesion but time will tell on that I suppose. Keep up the hard work.

Yes started with Loctite so have plenty of knowledge of the magic pixie potion!!

Well at least your build is prepping me for the future if I ever get my hands on one.