Its the same stuff Ben - PU adhesive. Thanks very much for posting the data sheet up which was very interesting. I noticed they recommend applying adhesive between the door crash bar and the door skin, think I will do the same as it will stiffen the door skin up and reduce drumming. PU adhesive has typically 25% flexture so it's not going to transmit vibration / noise

More work on the front floor, stripped most of the zinc primer I applied off with thinners. I only used this for temporary protection as the car was outside. Next job is to spray on 2K etch primer followed by 2K gloss.

Boot floor (another) trial fit

Decided to weld the rear valence assembly including all the stiffeners to the boot floor off the car

It's a bit complicated how it all goes together so I will post up some detailed pics.

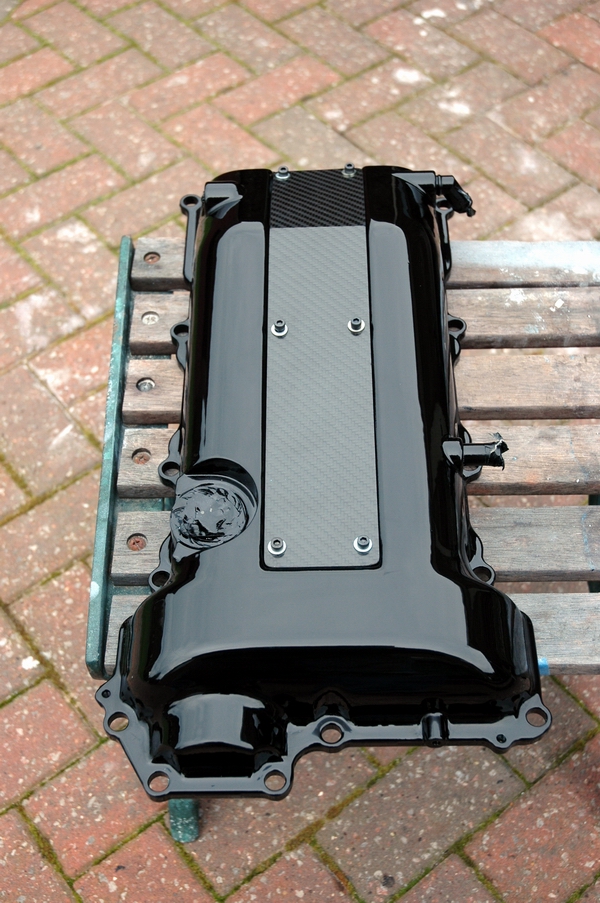

Underneath, would be uber cool to have a gloss paint job like this but I want it to last so it’s going to have a good dose of Shutz

Amp will be fitted here. It's great to be able to drill all the holes before spraying the shell.

Pete

Edited by Petrol, 05 September 2013 - 07:58 PM.