I did some research before doing this project and found that if i wanted to stick with the round nose mini i had very minimal space up front. I had found a guy in Australia that had put the radiator under the boot floor with coolant pipes from an MGF running the length of the car.

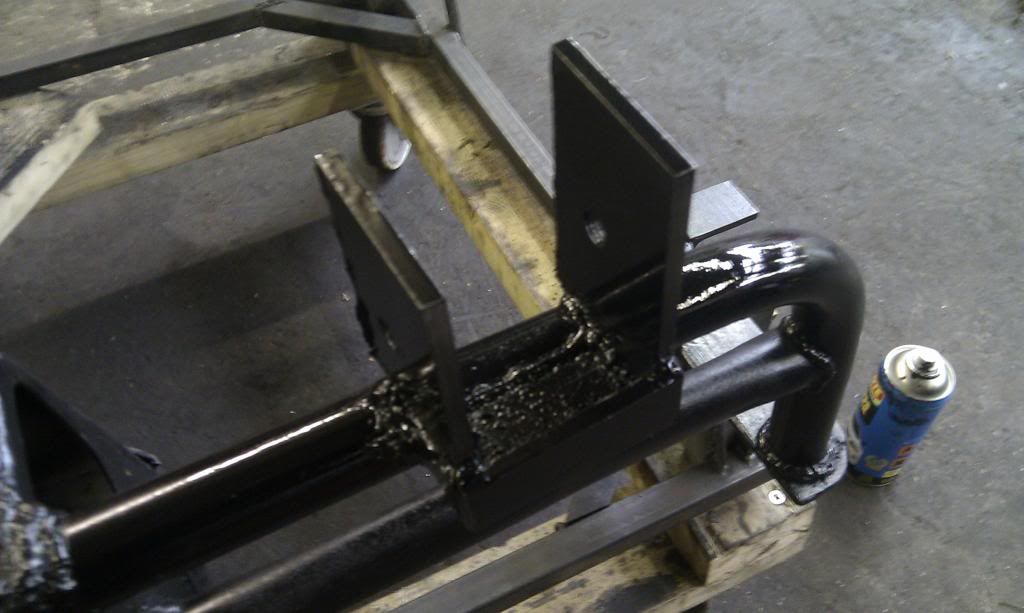

I felt that the radiator would be quite exposed to damage under there and so decided to put in the boot with a under car scoop. The air would be picked up off the road go through the radiator and out through vents in the boot lid.

Im not going to insult peoples intelligence by going through it step by step because hopefully the pictures are self explanatory.

First I needed to cut the boot floor, then create the sides of the scoop.

IMAG0108.jpg 23.66K

14 downloads

IMAG0108.jpg 23.66K

14 downloads

IMAG0112 (2).jpg 35.98K

12 downloads

IMAG0112 (2).jpg 35.98K

12 downloads

IMAG0113 (2).jpg 26.19K

13 downloads

IMAG0113 (2).jpg 26.19K

13 downloads

After that I coated the boot in Lightweight Dynamat to keep the noise of the cooling fan and fuel pumps to a minimum. I want to be able to drive this regularly and so make it as bearable to drive as possible. I also fitted some metal grate to the scoop inlet to protect the radiator from debris.

IMAG0195.jpg 74.82K

24 downloads

IMAG0195.jpg 74.82K

24 downloads

IMAG0240.jpg 32.69K

15 downloads

IMAG0240.jpg 32.69K

15 downloads

IMAG0280.jpg 38.98K

15 downloads

IMAG0280.jpg 38.98K

15 downloads

IMAG0283.jpg 36.39K

19 downloads

IMAG0283.jpg 36.39K

19 downloads

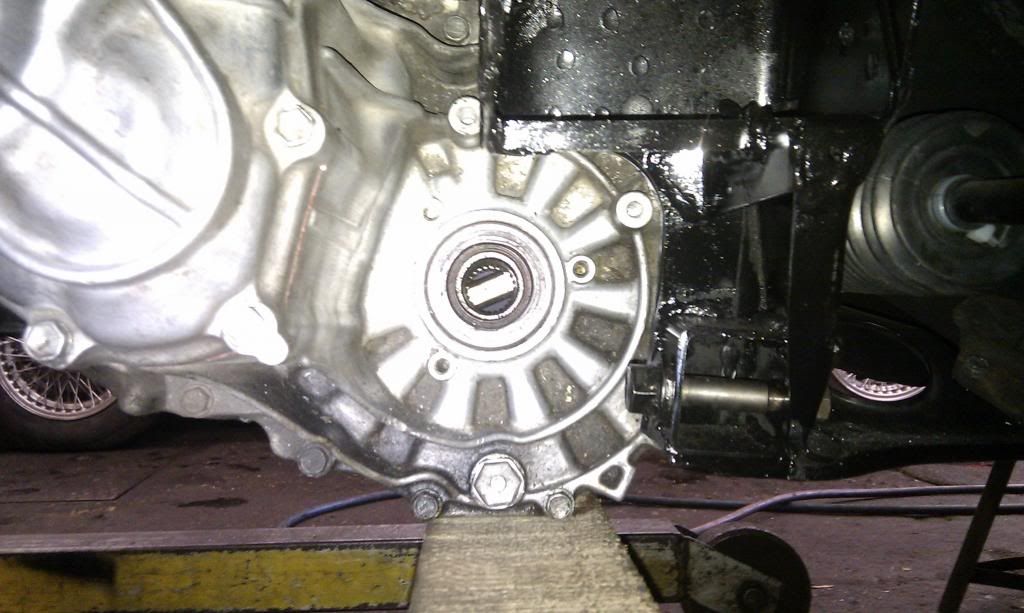

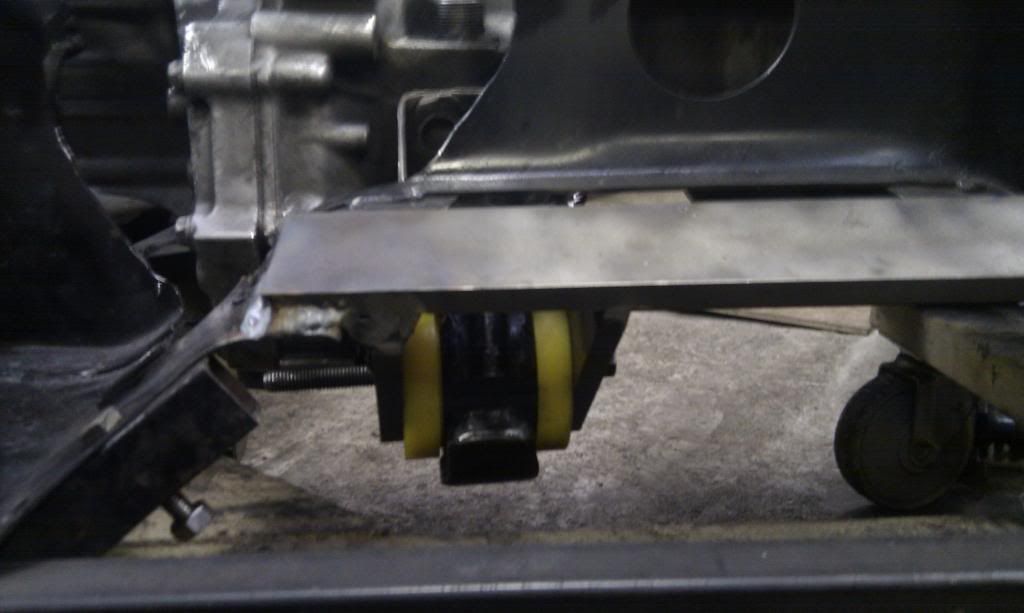

I had to make a fan cowling for the radiator to sit on so the air is channelled through it and its rubber mounted. I also need to run an electric water pump to take the stress away from the engine pump having to move coolant along the length of the car. Coincidentally the coolant connections on the Toyota engine and the radiator connections are 28mm external diameter. I have used copper pipe of 28mm diameter to connect the radiator. As you can see on this unit I made.

IMAG0449.jpg 48.21K

22 downloads

IMAG0449.jpg 48.21K

22 downloads

1 - Copy.JPG 40.91K

31 downloads

1 - Copy.JPG 40.91K

31 downloads 3 - Copy.JPG 45.55K

30 downloads

3 - Copy.JPG 45.55K

30 downloads