Originally a 998, this 71 Clubman had a fair amount done to it by its previous owner - full respray in Rover Hurricane Grey, 1380 A series fitted with a Weber 45 (this was then changed to a HIF44), Minispares 7.5" disc conversion, Gaz shocks, and probably a fair amount more. He had it running on 13" superlights but they got ditched in favour of 10" Exacton's which i've become a big fan of!!!!

As things crop up during the build i shall explain more about the bits previously done on 'Barry' (as he was christened by previous owner...kinda stuck really) as there is a little story here and there!!

My plan is to turn 'Barry' into a Historic Rally car, to initially do Night Rallies and Historic Road Rallies, with the ultimate end goal of doing 'proper' stage events....if funds allow!!! The original colour of Aqua will be reinstated further down the line when time allows. You'll see the original colour here and there....as the spay job done on the car (by professionals i may add!!!) was terrible and is pealing in places!!!

Anyway, enough of the boring stuff, here's some pic's.......

Did a production car trial over the summer (what there was of it!) and finished 5th overall and second in class....not bad for my first go, and considering the car that won overall was a 4x4 celica i think we did well.....and i got lost on one of the hills!!!!!! Note to self....always listen to navigator (wife!!!!). Cheers to Broughton and Bretton Motor Club for running such a great event.

The rally prep begins........

First up, 6 point Safety Devices Roll Cage....

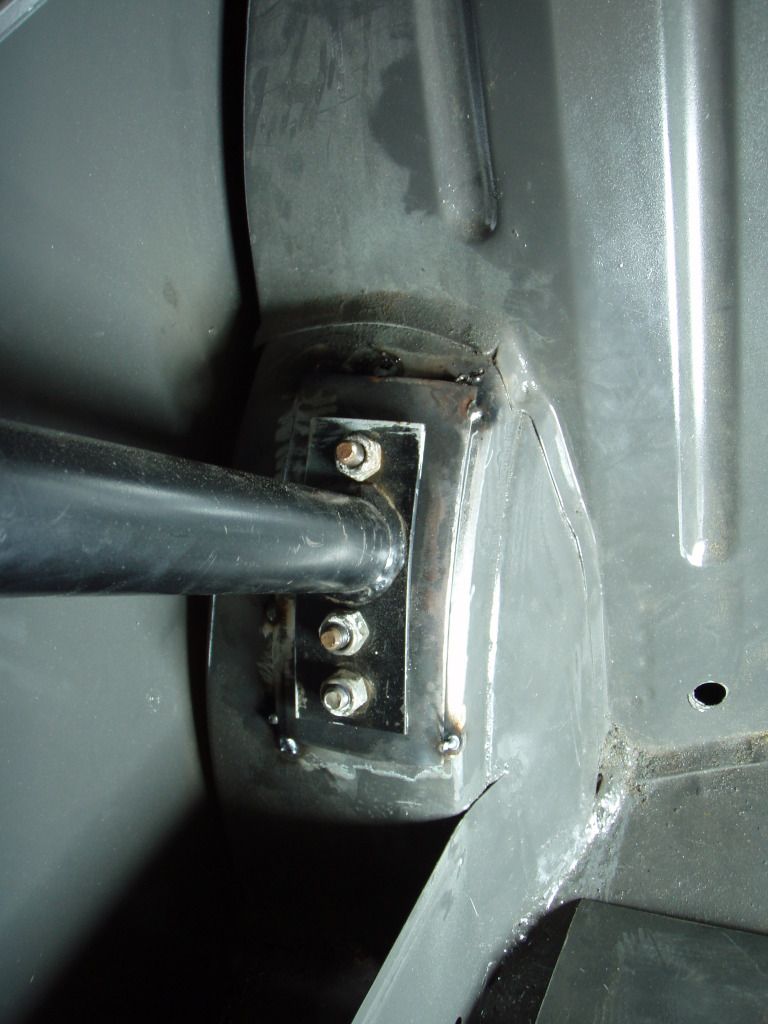

I really didn't want to cut the rear bins out as i kinda like them and they are one of the mini's little querks, but in order to weld in the spreader plates the bin had to get the chop. Made life a whole lot easier and if anyone is considering doing a cage...cut the bins. I'll be welding mine back in once plates are fully seam welded and painted.

Just temporary fitted for the time being. 3mm spreader plates (exceeding MSA size spec's) tacked in to be fulled seam welded shortly.

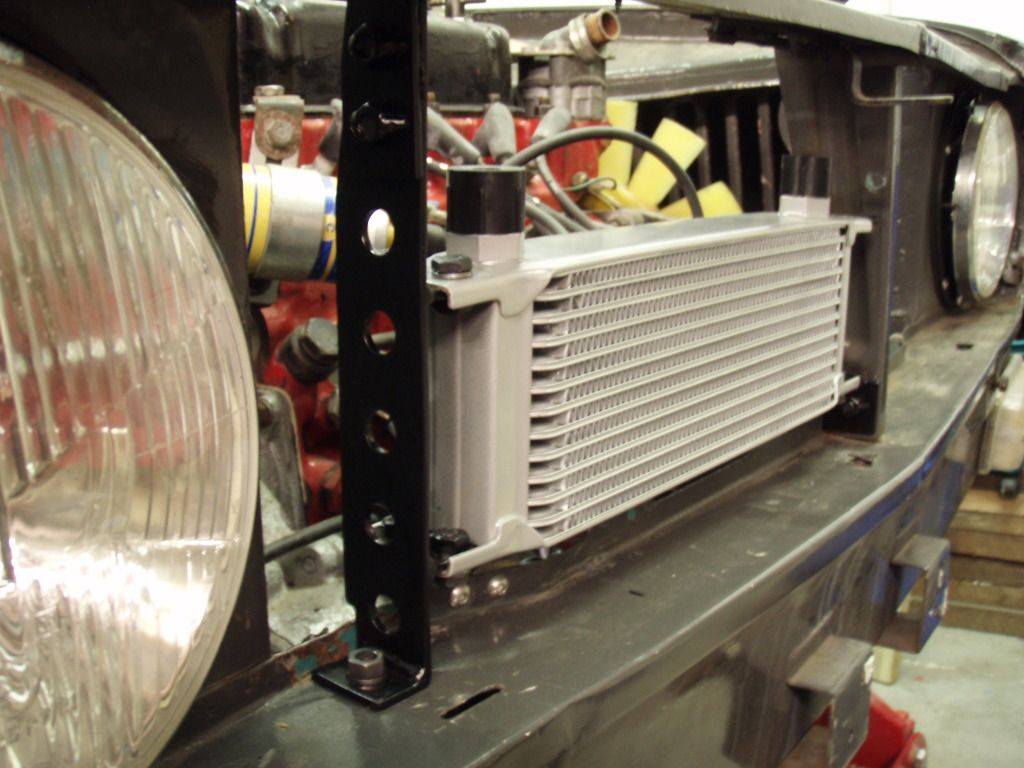

Home brewed Oil cooler bracket was fabricated so cooler is kept nice a high up behind the grill out of harms way....fingers crossed!!!! All made of 3mm steel with captive nuts welded in so only one tool