UPDATE TIME!!!

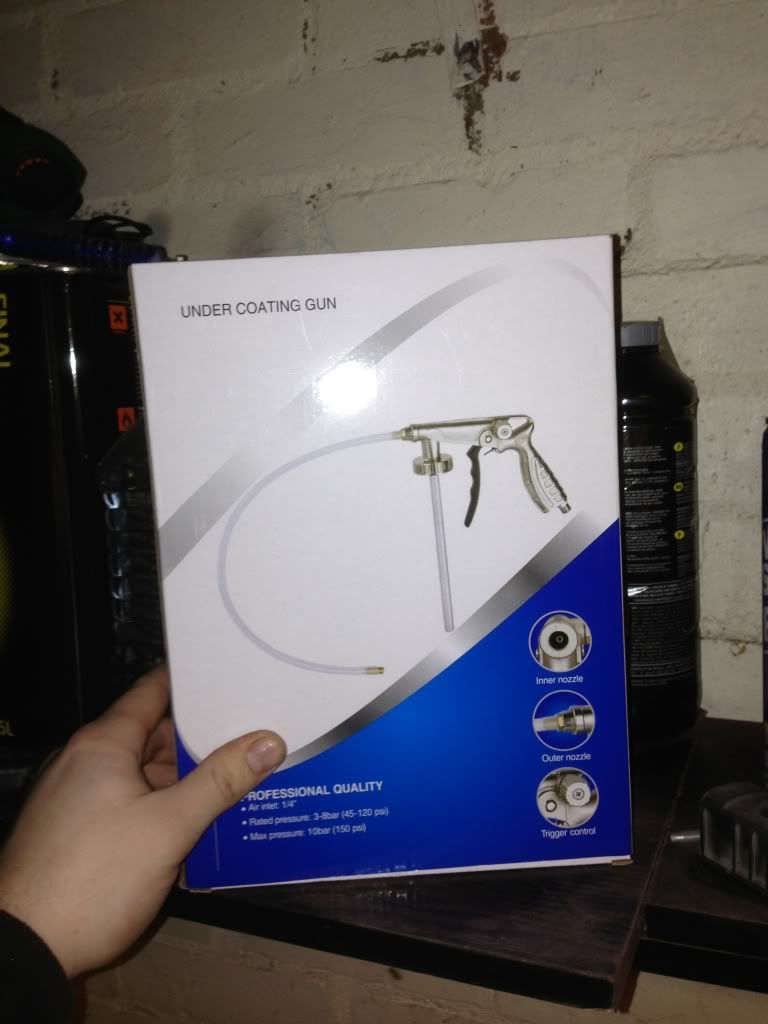

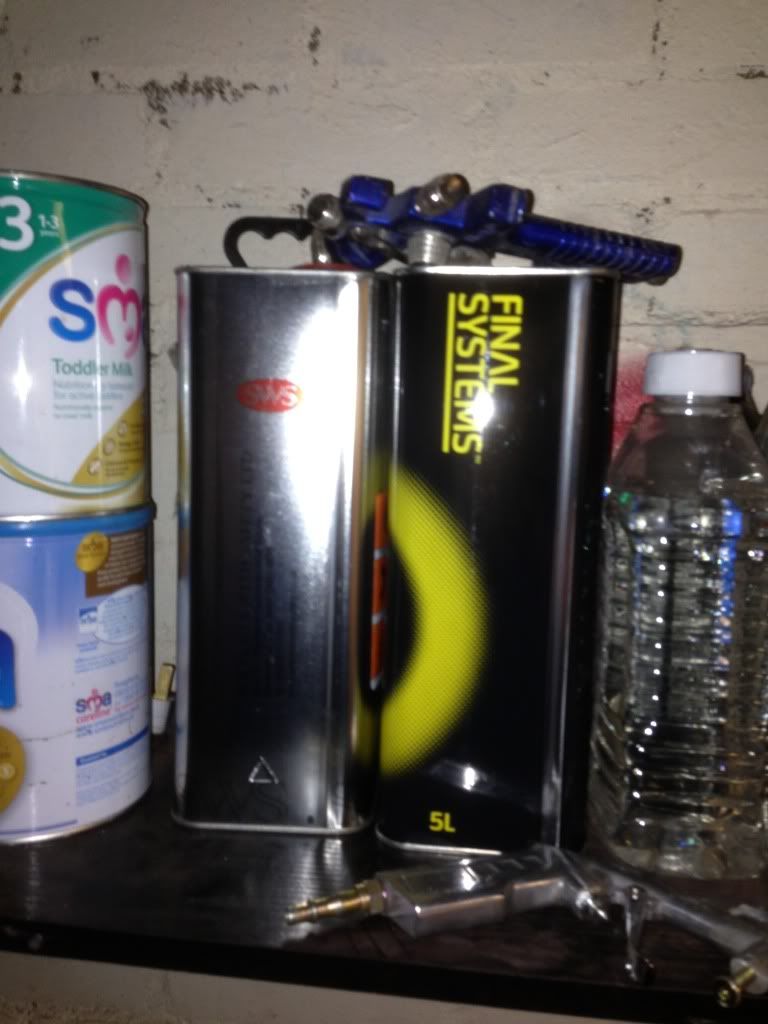

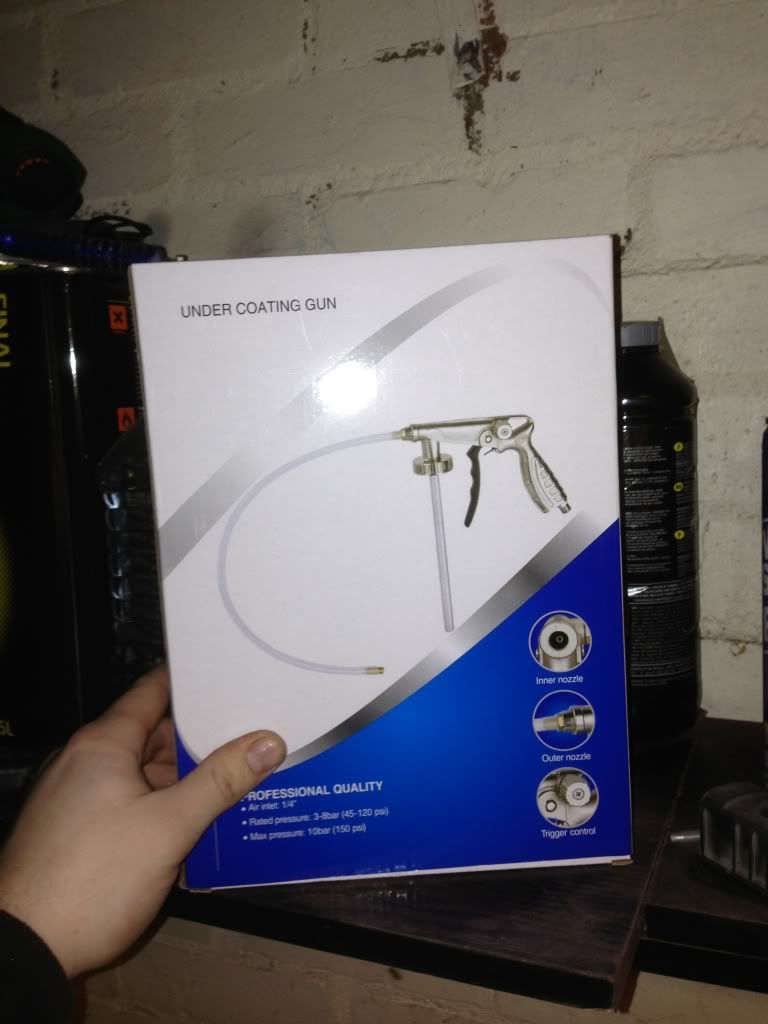

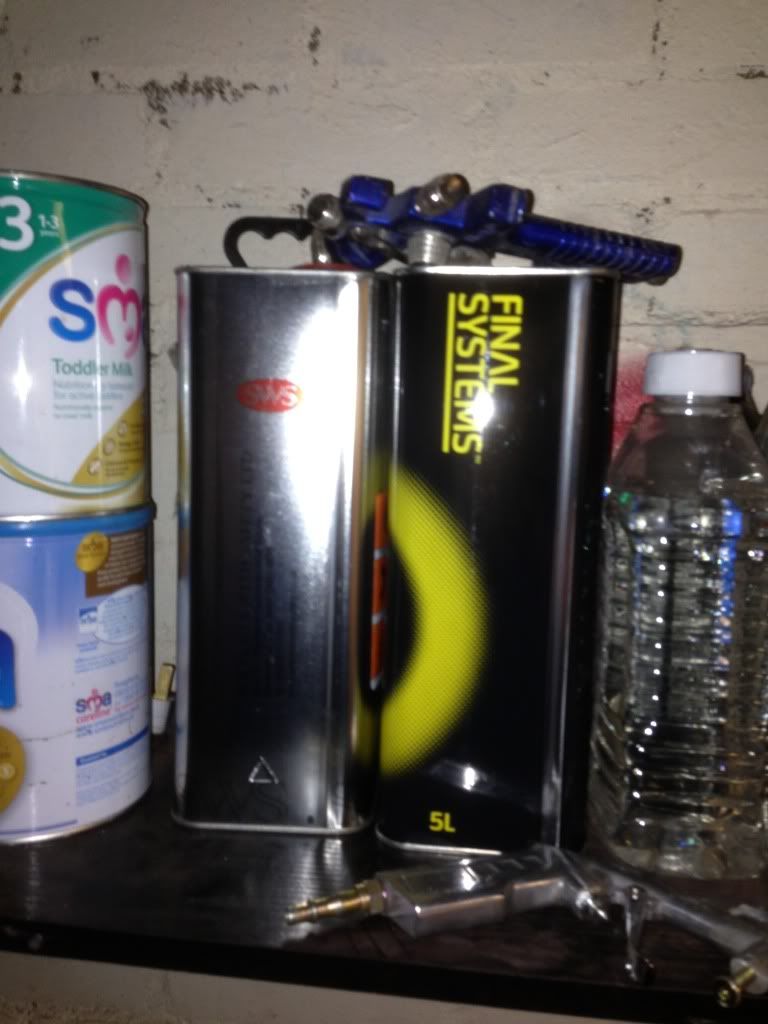

finally i managed to drag my arse into the garage and got some work done as all i have been doind lately is buying stuff so some pics of that first and as usual a massive amount of useless pictures

if you look closely you may notice the front panel has no bumper lip got the full front end for 110 delivered

nice little low milage mg metro short block with kent 276 cam and duplex rota slide timing system

and now for some work. left to do on the front shell wise was front subby spreader plates so i cut these out

and this may be a little ott but fully seam welded

made the other one and cut the corners off to clear the tunnel

then set about welding them in plenty of pluge with seams all the way round they are twice as thick and twice as large as standard so should hold the solid subby in nice

and then both done cleaned off and seam sealed the whole bulkhead

and then sealed the front of the bulkhead ready for the stonechip next week hopefully after the a panels go on

next weeks plans are a panels on hover out the inside flip over clean the bottom off re-prime where necesary and stonechip then stonechip the inside floors up to the heel board. For now that is all i am affraid sorry for the mass of pictures but i love taking them

Comments always welcome cheers darren