Right i should really get to work, this mini is distracting me far too much

Kieran

Posted 12 March 2013 - 08:16 AM

Posted 20 April 2013 - 08:55 PM

Edited by KieranB, 21 April 2013 - 08:40 AM.

Posted 21 April 2013 - 10:04 AM

Posted 21 April 2013 - 12:26 PM

Looking good now Kieran it won't be to long now also are you using gas with your welder if your not try and get hold of a gas bottle it will help loads

John

Posted 29 April 2013 - 12:34 PM

practice makes perfect :) as long as your welds are strong and have good penetration you should be safe

Posted 29 April 2013 - 10:28 PM

They appear to be very strong but it takes about 3 damn layers to make sure they are ok. I'm good at grinding welds down that's for sure

Auch whilst I'm on i've got a couple pics, got the gearstick extended. Ten points to anyone who can name the car part that i donated to the making of the gear stick extension

And then some practice, i have been welding parts together but thought this one was appropriate ![]()

Car is going for exhaust this weekend hopefully, wont have an update until the following weekend :)

Kieran

Posted 30 April 2013 - 06:28 PM

Tie Rod?

Posted 30 April 2013 - 08:13 PM

Tie Rod?

WINNER!!

Edited by KieranB, 30 April 2013 - 08:57 PM.

Posted 01 May 2013 - 09:20 AM

Haha. Out of interest why have you extended it?

Posted 01 May 2013 - 10:06 AM

Posted 01 May 2013 - 04:31 PM

Haha. Out of interest why have you extended it?

The reason is the honda gear stick is very short and the driving position felt horrible when i test drove the car, I may have extended it quite a lot but the throws aint that bad at all because of the bend.

Are you using a hand held welding mask by any chance? Also, whats the rear of the metal look like when you have welded? Looks to me that the weld is sitting on top of the metal, rather than "becoming" part of it

No i'm using one that clamps onto my head. Why?

The weld in the pic aint a great example and you are right there isnt a great deal of penetration on the other side but other welds I've been doing are penetrating. I'm saying all this and you're probably going "Pah I see no photo evidence". Hopefully i'll get some more pics up this weekend if the weather is nice :)

Kieran

Posted 07 May 2013 - 11:37 PM

Just bear in mind Kieran when you change gear in a mini its a bit different once an engine swaps gone in, new linkage and stick all makes it more work sometimes, and more clunky aswell. Chances are on hard changes any weak welds will show then go

Liking the tie bar trick though - innovative, gotta be a first!

Posted 12 May 2013 - 08:21 PM

Got an update, just a small one though

The mini is currently not with me as it's over getting the exhaust made for it. I wanted something unique so gave it to my mates brother who is trying to setup his own business. His work is mainly farm equipment but he used to made all sorts of stuff at his old work including roll cages and has made a few exhausts before.

So a few pics of the mini on its trip over the hills to its temporary home

And i just popped over tonight to see how he has got on. Was welcomed to this ![]()

He has done up to the gearlinkage, the tricky bit is done and is now just a case of taking it up to the rear silencer and fully welding it up. Really happy with the way it looks just now though.

Its fair to say I'm already missing my mini, 18months of having nothing to work on soon took its toll

![]()

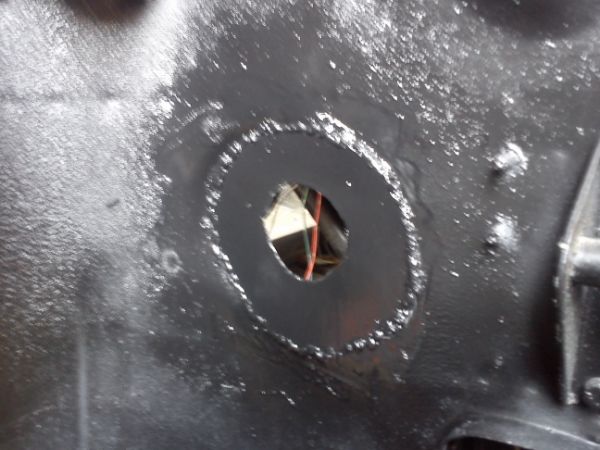

My electrics loom has also turned up

Spent most of my time trying to figure out what the hell goes where because the guy didn't label it but think i've got it sussed.

Thats about it, should get the car back next week ![]()

Kieran

Edited by KieranB, 12 May 2013 - 08:27 PM.

Posted 12 May 2013 - 09:24 PM

Posted 12 May 2013 - 09:32 PM

That exhaust is looking very nice Kieran you should have a nice sound from that. What back. Box are you going for ?

Thank you, the system is 1.5" on the 4 pipes off the manifold and then 2" from where they branch into 2 pipes and continues that size all the way to the back. The back box I'm not sure what it is. I just requested a stainless oval back box and we will use the tip from my old one which was a RC40. But ye should sound awesome ![]()

0 members, 1 guests, 0 anonymous users