there is plenty of topics about building a gearbox but none about stripping the box in the first place, i have tried to take the pictures so that people can understand how to do it (and its the first gearbox that i have stripped) so bear with me on this one!!

here goes, i will try to explain the best that i can.

firstly, you will need to remove the differential, i did not include a picture of this as its pretty much self explanitory, basically you need to undo the bolts that secure the diff side covers on and remove both of these (they may be a bit stubborn so a soft faced hammer will be useful here) the diff side cover on the clutch side of the gearbox also secures the spring and plunger for the gear selector rod so be careful when removing this cover, the spring, plunger and ball should be removed and put somewhere safe, then undo the nuts that hold the diff casing onto the back of the gearbox, remove the differential from the gearbox and put to one side, you will now need to lock the gearbox into 1st and 4th gears, to do this rotate the selector rod anti clockwise so that it disengages from the bell crank levers, you will now be able to engage 1st and 4th gears as in pic below

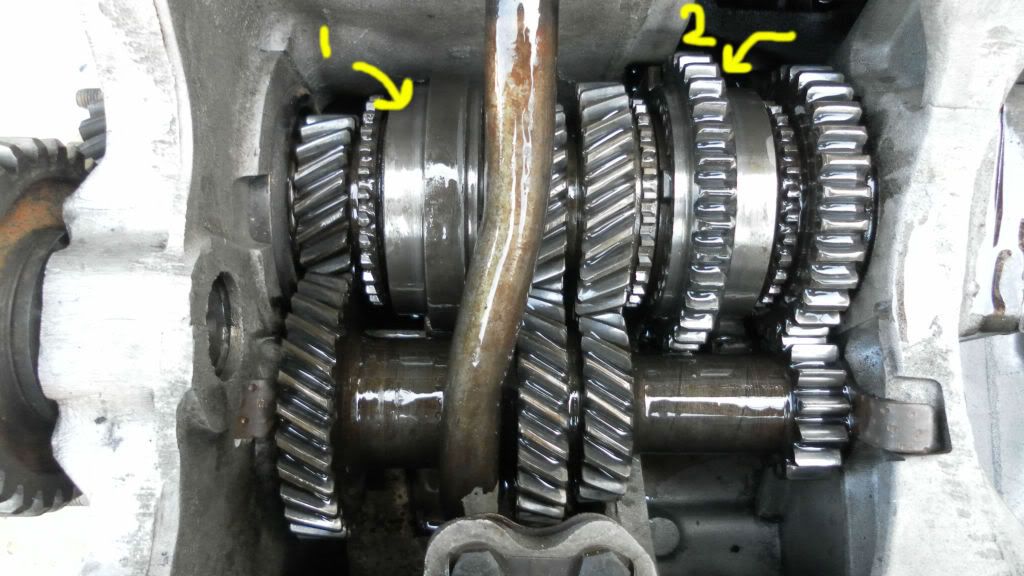

move the syncro hub (arrowed 1) to the left as you look at the picture and the hub (arrowed 2) to the right, the gearbox will now be locked into 1st and 4th gears.

remove the speedo housing from the gearbox (self explanitory)

next you will need to undo the first motion shaft nut and the pinion gear nut ...remember to tap back the locking tabs first!! (these nuts will both be very tight and you may have to turn the gearbox upside down and get a (heavy) assistant to stand on the gearbox while you undo these nuts) remove both nuts and store somewhere safe.

now return the gearbox back to the neutral position by moving the syncro hubs back into their original position.

remove the differential pinion gear (it just pulls off) and then undo the nuts that hold the bearing retaining plate, remove the plate and also the plate that holds the reverse gear idler shaft in place.

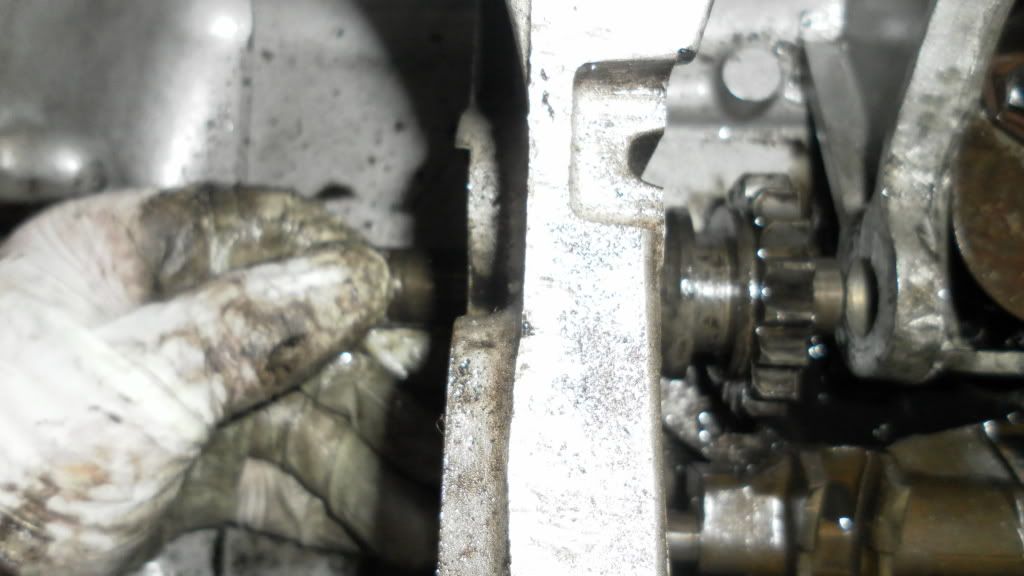

next you will need to remove the laygear shaft using a suitable drift.....(pic)

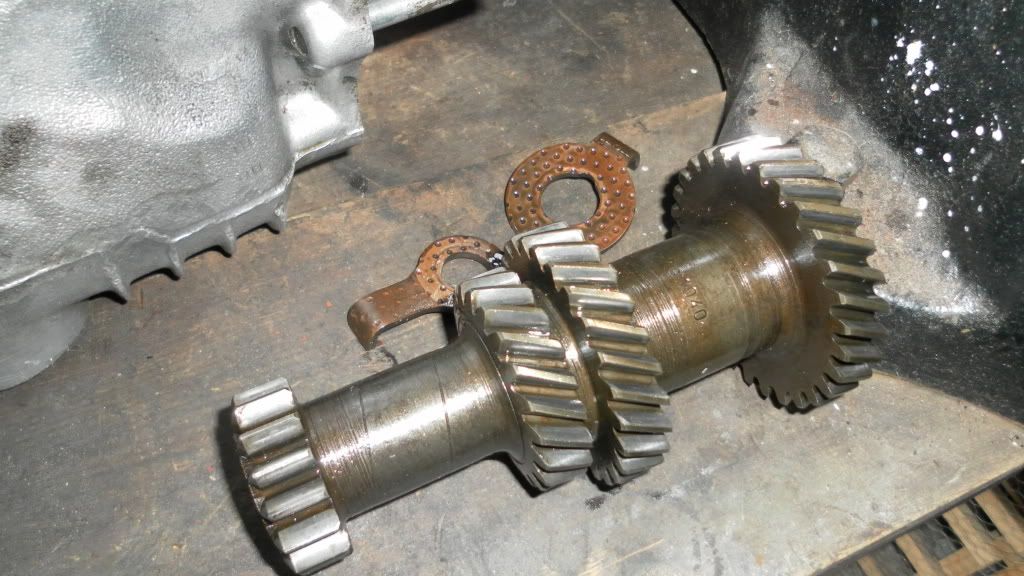

pull the layshaft out and now the laygear can be removed from the gearbox

now you need to remove the input gear from the end of the 1st motion shaft (the nut should have already been removed earlier)

remove the circlip that retains the first motion shaft bearing (you will need circlip pliers for this)

now you will need a suitable drift to tap the bearing out from inside the gearbox, the 1st motion gear will come out with the bearing (pic)

first motion shaft and bearing (pic) check this bearing for wear and replace if needed

now you need to tap the end of the mainshaft with a suitable drift so that it gives you enough room to access the main double roller bearing (pic)

now use a suitable drift to tap the double roller bearing out from the gearbox casing (be careful whilst doing this as these bearings are very expensive) ...... (pic)

you will now be able to remove the mainshaft and gear cluster (make sure that you hold both of the end gears onto the shaft while you are lifting it out) it is a bit fiddly working the cluster out past the selectors but be patient.

mainshaft and gears removed (pic)

you can now remove the reverse gear idler shaft (it just pulls out) and the reverse idler gear (pic)

next undo the 2 bolts that retain the oil pickup and remove it from the gearbox

apart from removing the gear selectors that about it, you will end up with a pile of bits like this!!

i hope that i explained it well enough for you to understand........theres loads of videos etc on rebuilding the gearbox.

Edited by oltonlad, 31 March 2012 - 07:56 PM.