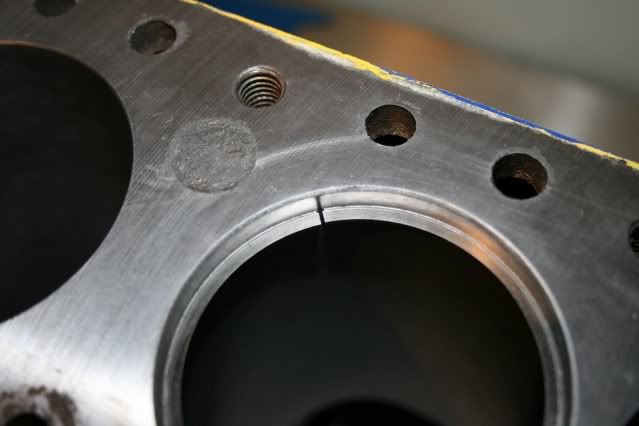

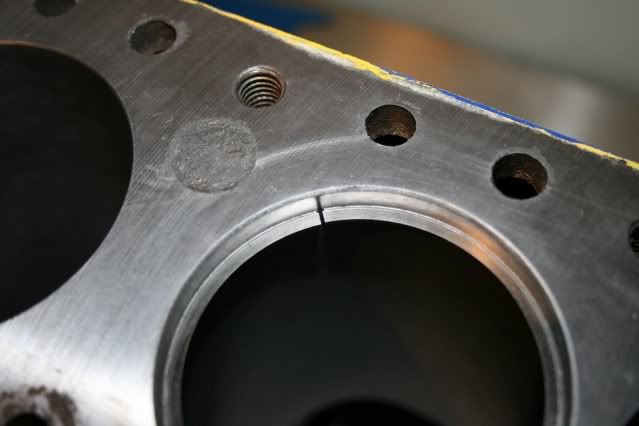

I have had a look at the rings and was wondering what the end gap should be

I take it I am measuring it correctly ??

What are the problems if it is too big or small ??

Thanks,

Graham

Posted 17 January 2012 - 06:56 PM

Posted 17 January 2012 - 07:46 PM

Posted 17 January 2012 - 08:34 PM

Posted 17 January 2012 - 08:52 PM

Posted 17 January 2012 - 09:04 PM

Edited by grahama, 17 January 2012 - 09:05 PM.

Posted 17 January 2012 - 09:11 PM

Posted 17 January 2012 - 10:15 PM

Posted 17 January 2012 - 10:25 PM

Posted 17 January 2012 - 10:45 PM

Posted 17 January 2012 - 10:59 PM

Will try again tomorrow and test all the way down the bore with the piston as a guide. Should everything be oiled up first or is it better to do it dry??

Graham

Posted 17 January 2012 - 11:43 PM

Edited by bmcecosse, 17 January 2012 - 11:44 PM.

Posted 17 January 2012 - 11:53 PM

Posted 18 January 2012 - 05:27 PM

Doug, do you think that ring gaps have increased 'as supplied' over the years. I can remember in the 60's and 70's having to linish a bit off the ends of rings to get sufficient gap.

Posted 18 January 2012 - 06:10 PM

Posted 18 January 2012 - 06:10 PM

0 members, 1 guests, 0 anonymous users