This bits for you then Danny1...

So first thing to do is to set the DTI up on piston number 1, Thats the one nearest to the front, (water pump end), of the block. Set it with a small preload, you will get much more accuracy with the readings

Turn the crank untill the piston is at TDC...you will see the dial spin round and then stop.it will then go back the other way..turn the crank untill the dial reaches the point where it changes direction. This point is TDC. Now zero the dial and move the crank back and fore a small amount to check its at zero on TDC.

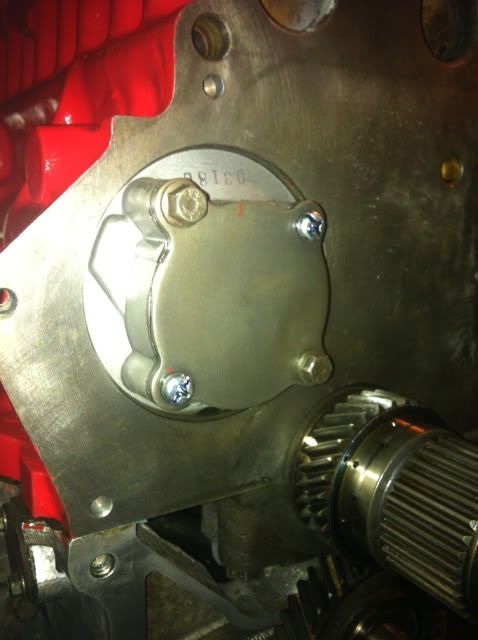

Next you can loosly fit the protractor wheel to the end of the crank and fit a bit of stiff wire. I use a bit of fence wire and attach it to the timing cover bolt. Turn the wheel so its TOP mark is uppermost and tighten the bolt so its fixed to the crank..Then move the bit of wire untill it points to the TOP mark..

Ok so now you are at TDC with a zero reading on the protractor wheel...

Next you pop a push rod down the number one inlet hole, (second one from the front) and make sure its seated in the follower. Then you can set up your DTI onto the push rod..again with a little preload.

Dont wory about the reading on the DTI at this stage. Right so now you need to turn the crank forwards, Thats clockwise when looking at the front, You will see the DTI spin round a few times and then slow down and stop. move the crank back and fore untill you are sure the needle is at the point where it changes direction. Again zero the DTI. The cam is now at maximum lift on number 1 inlet .

My protractor wheel was reading 112deg ATDC at this point of maximum lift.

Turn the crank backwards untill the DTI reads 0.025"

Next you need to slowly turn the crank forwards until the DTI reads 0.005" mark..Mine is a metric DTI so the reading is 0.127mm. you will find this quite tricky to get exact and a bit of forwards and backwards movement on the crank will be required to get the reading spot on, but dont cheat here as its critical to your timing.

Note that because the crank has actually moved slightlybackwards at this stage my DTI has a reverse reading, but its 0.127mm from the zero point.

Once you have got it spot on then take a note of the reading on the protractor wheel

Mine shows 94 deg.

Next you continue to turn the crank forwards untill the DTI goes back to the 0.005" mark. it will move away and go back as the cam lobe goes over the max lift and drops off the other side..then you can take another reading off the wheel..

Mine says 124.5 deg..

Right so now its time for the maths...you add the two wheel readings together...94+124.5 = 218.5

next you divide that by 2...so 218.5 divided by 2 equals 109.25 deg...And thats what my cam its timed in at 109.25 deg after TDC..

Now considering the max lift reading was 112deg..thats my cam timed in 3 deg advanced. The Spec for the MG cam from Rover says it should be 110 deg ATDC. So im pretty much bang on the money at dot to dot..I could retard it with offset woodruf keys by a few degrees and maybe gain a small amount of torque, but im not going to bother with this spec of engine. Dot to dot turns out to be fine.