Edited by brandon7, 23 March 2008 - 06:05 PM.

PROJECT RAPID!!!!

#391

Posted 23 March 2008 - 06:04 PM

#392

Posted 23 March 2008 - 06:23 PM

Took the car down to the industry estate. Think im having the same problem as willy dastardley had. dont seem to have full revs so it seems like i was short changing bout it wouldnt rev anymore? Was that because it was over fueling? definatley needs tuning and setting up!!!

Have a listen see what you think. sorry bout the quality will get somemore tomoz if its nice and dry

vid1

vid2

vid 3

Also really gutted i think 1 of the wheels may have a buckle or the pcd drilling is outs hmmmm will have to investegate. the guy who put the tyre on didnt say anything but ibe notice quite alot of balance weights on the wheel. can wheels be repaired with a buckle or is that it?!!!?

VIDEOS WORK NOW

Edited by dean_chad, 23 March 2008 - 06:47 PM.

#393

Posted 23 March 2008 - 06:36 PM

#394

Posted 24 March 2008 - 11:48 AM

#395

Posted 24 March 2008 - 01:32 PM

By the sounds of it, the engine timing is faaaaaaaaaaar out mate. It's a quickish job (about 10hrs) for someone who knows what they're doing.

Where did you get the alloys from and for how much??

Edited by Fevmeister, 24 March 2008 - 01:33 PM.

#396

Posted 24 March 2008 - 02:05 PM

Timing out? How do you adjust the timing on a carbed R1 engine? would be interested to know.Are you only going to put the one seat in??????

By the sounds of it, the engine timing is faaaaaaaaaaar out mate. It's a quickish job (about 10hrs) for someone who knows what they're doing.

Where did you get the alloys from and for how much??

If its not on a standard air box and exhaust it will need jetting.

Dean, what will it rev to while driving in 3rd gear? Is the rev limiter coming in too early? Could be stuck in a neutral or clutch-in map.

And by the way its looking mint.

#397

Posted 24 March 2008 - 02:34 PM

Cheers

David

Edited by R1mini, 24 March 2008 - 02:35 PM.

#398

Posted 24 March 2008 - 02:39 PM

It takes a while to get used to driving a bike engined car, Ive driven a r1 car and it seem bizzare to rev it past 13 in each gear compared to about 10.5 in the busa. Good progress though mate, downhill all the way now.

I would look at the hub drilling first to be honest, not that im insulting your engineering skills, try and run the wheels on anothe car first to eliminate the wheels being Knackered.

Cheers

#399

Posted 24 March 2008 - 05:10 PM

Dean, what will it rev to while driving in 3rd gear? Is the rev limiter coming in too early? Could be stuck in a neutral or clutch-in map.

And by the way its looking mint.

koss i will have to wait until i get the jump wire for the exup because the evodash does the tacho tango like the original dials so every few seconds it reads 8000rpm

Sounds like your changing gear far too early!!!

It takes a while to get used to driving a bike engined car, Ive driven a r1 car and it seem bizzare to rev it past 13 in each gear compared to about 10.5 in the busa. Good progress though mate, downhill all the way now.

I would look at the hub drilling first to be honest, not that im insulting your engineering skills, try and run the wheels on anothe car first to eliminate the wheels being Knackered.

Cheers

Yeah in those vids i thin i was getting a bit change mad!!!!! when i left it to rev i could tell it wasnt getting full rpm. just sounded a bit ruff as its heading up the top end, i think i should get it finished then set up. Is t.t.s the closest to me then? quite fancy pdq tuning but its a little far at 2 hours! I live just south of Birmingham

As for the pcd an engineering company did all 4 so i doubt they would have got the 1 wrong but yeah your right it could just as well be a mistake by them. Im gonna put the wheel on the other side see if it swaps the fault. Ive found a company who could fix the buckle if thats what it is.Was just reading though d.d's thread and noticed he had movement when the cv joint was too tight. must check that!

yeah driving it is awesome shame its only in a straight line wont be long though

nice 1 fellas so we recon it could be jetting?

Edited by dean_chad, 24 March 2008 - 05:15 PM.

#400

Posted 25 March 2008 - 08:25 PM

A few months ago i was toying with the idea of having the manual change lever just left loose just incase the solenoid unit fail and i could get myself out the shizzle by bolting it back on. Just thought, as the extended lever was in exactly the right position to bolt the manual lever to (also 90deg to solenoid optimum for performance) i would just see how much speed and power i would loose in the change. I drilled a new hole the same position where the original lever would be and gave it a lick of paint .

Lots of dust around that needs cleaning that will be 1 of the last jobs

Im totally buzzing, the solenoid has 40pound force near end stroke so it changes gear easily with the manual lever attatched. I dont think it will loose to much time in the change either i spose it will only be milliseconds. The fact is I THINK IT LOOKS TRICK....... a gearstick moving on its own and lets be honest im not gonna miss the odd millisecond, its not like it would matter off the lights or on a track day!! It might however interfere with the trickshifter engine kill but time will tell on that 1

The solenoid is just placed on with mole grips at the moment ive measured where it needs to be postioned on the engine steady bar which will get the strengthening treatment tomorrow and a bracket welded on so all 3 mount holes are used

anyways here is the unit working. The bar press button have just been rigged up to see it workin obviously they are going to be attatched to the paddles eventually unless someone wants to sit in the passenger seat and change for me? hehehhe. couldnt help chuckling as everything seem to be made for where ever i was poking it!!

Oh its a big file so be patient, if it doesnt work i will save it as a smaller file

LOOK NO HANDS!!! VIDEO CLIP

DEAD CHUFFED THIS IS WHERE IT GETS INTERESTING NOW!!!

Edited by dean_chad, 25 March 2008 - 08:29 PM.

#401

Posted 25 March 2008 - 08:52 PM

#402

Posted 25 March 2008 - 09:01 PM

#403

Posted 27 March 2008 - 08:44 PM

finished work a bit early so removed engine steady,made up a bracket and ran a weld over it and a lick of paint. Another job out the way. They all add up but if i do 1 at a time i will finish eventually!

Oh had a read up on this exip fault. I looked at buying an exup motor and just attatching it. A servo costa around £50 and the little controller around £100. I figured i would try the resistor route. Ordered a pack of 10 off ebay last week and had a go. link the white/red and black/red wires ( i believe this is the same for r1's 99-04 but dont quote me on that) for the exup motor with a 7.5kohm resistor. in the ignition on postion the fault still occurs, wierdly the rev counter only faults to 3500k now. When the engine is running there is no fault to be seen which is great. saved myself a few quid! Also having the jump link in the engine runs at normal spec or so they say

I have 7 more resistors left if anyone else has the tacho tango problem and wants 1 just pm your address

Dean

Edited by dean_chad, 27 March 2008 - 08:57 PM.

#404

Posted 29 March 2008 - 11:17 PM

#405

Posted 06 April 2008 - 09:18 PM

Had all week off work to get things done and have to say its almost there......

fitted all the front end parts now BUT going to have to change the clutch hose to flexi as ive made it solid throughout derrrrr!! fitted washer and whiper motor wiring. Found it realy frustrating using 1 of the haynes mini manuals as the wiring diagrams dont show how some units workjust the wires going into it. As i never removed anything from the car at the start of the build and im using a different fuse/relay module i had to sus it out. Ive never had to wire up a wiper motor so finding out how the park postion is enabled was interesting. I think thats the best part about building something, you have to know how worything works in order to attatched its not just following a diagram.... you make your own plans!!!

finished off the back end

muts nuts

finished off doors just need inner window moulding which is in the post. the poly windows needed trimming as i used the inner piece of felt

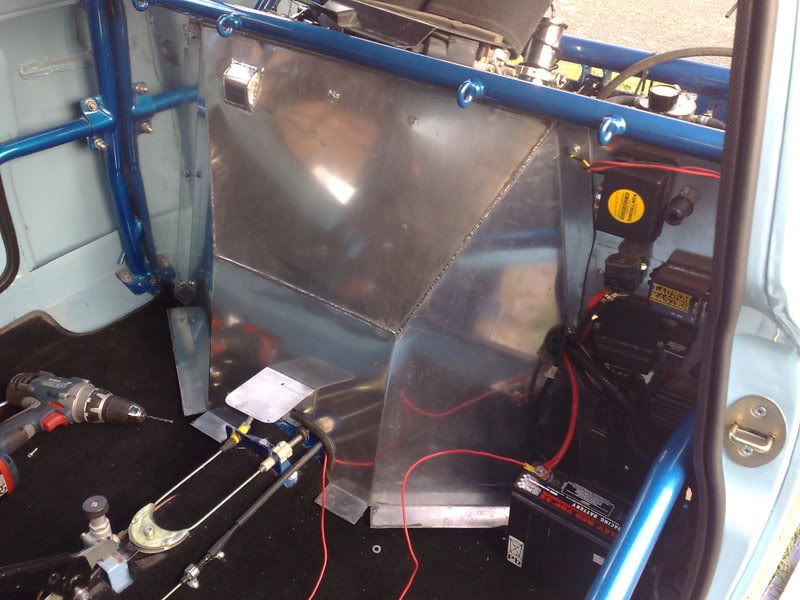

travelled up to collect bulkhead, Nice 0ne Mark!! spent about 5 hours removing the sound deadening and polishing. recon it turned out pretty good. Tidied up all the wiring and added the launch control unit (needs wiring up though).

from this to this

to this

The thermostat was fouling on the middle panel so i modified the steel pipes coming out the head an swopped them round so its now moved back a little

spent the reast of the time sorting out the wiring. Wished i had done the majority of wiring at the back of the dash before fitting it! I now have a permanemt crossmember mark across my back! Had the front light brackets modded and re-chromed so they now fit the crosshair lights nice and tight, they sit in the original mini bowls too

Anyways shouldnt be long now!!

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users