Ok an overdue update, We've been plodding along with it and doing other stuff swell like putting insulation in the garage and collecting 2 other minis and doing an few bits on the Ritz, one being sheldon the RSP below. Anyway stuff we've done.

Modified the boot hinges and smoothed them out.

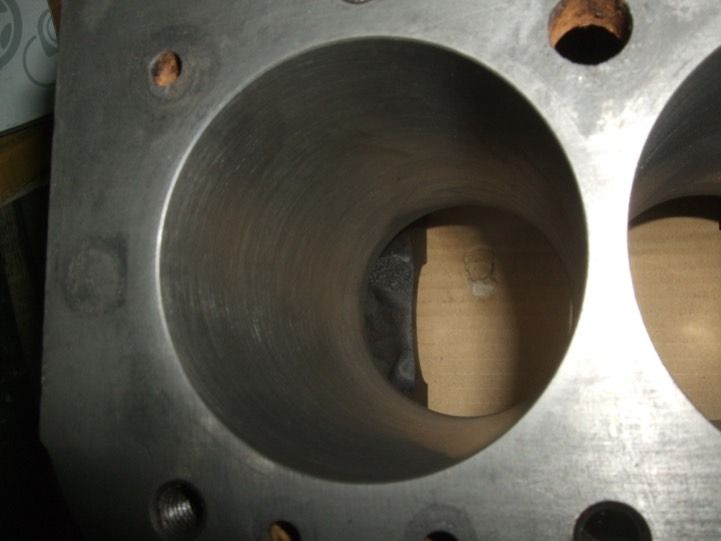

Got the rusty sprite into the garage to steal the engine, which has been all stripped down, the gearbox sent off to guess works, the block re-bored and crank re-ground.

Had a bit of a problem removing the flywheel, we had a laser one which we put a bit too much force on and push the centre out and damaged the first thread in the crank.

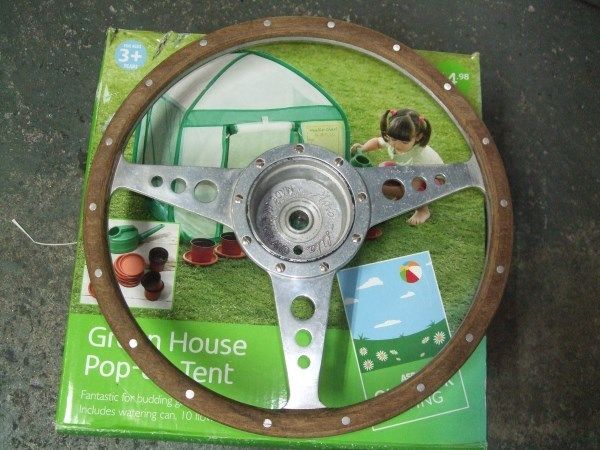

So bought this beast from guess works. Which with a breaker bar and leaning on it still didn't get it off after leaving it over night, so put a bit of heat on it and off it popped.

split the gearbox and block.

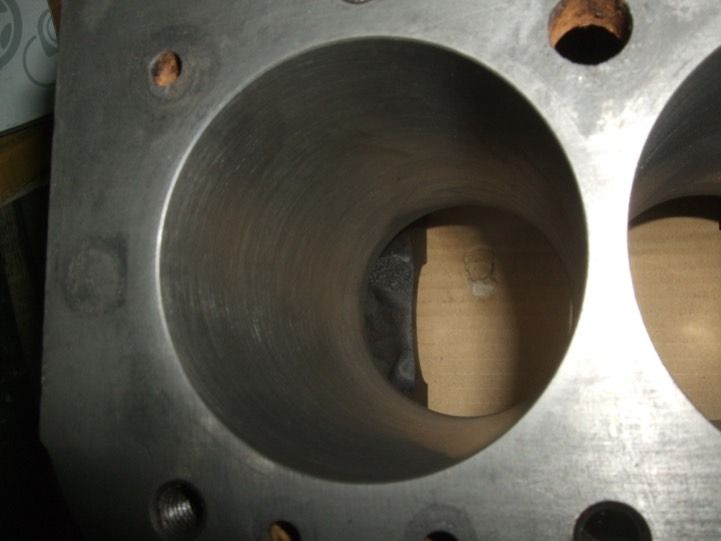

And freshly re-ground and re-bored with new pistons and thrust washers etc.

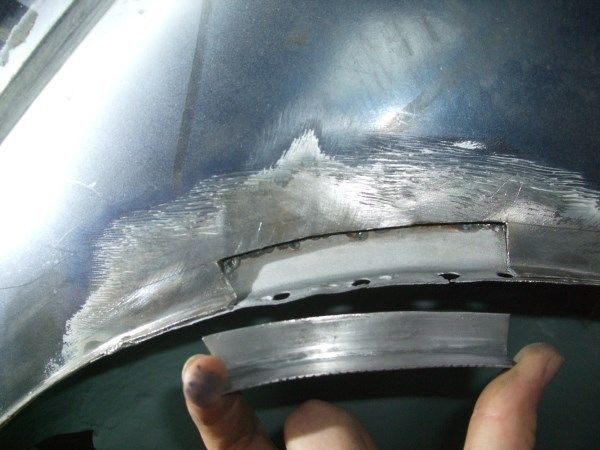

I've cleaned off the underside of the bonnet and welded the cracks on the bends where they are prone to going.

Cut and bent some 1.2mm sheet for the strengtheners, welded them to the bits that i cut off my old bonnet.

De-oxed the underside.

Then zinc sprayed it and glued them the majority of the way with gorilla glue and welded it to the corner strengthener where the hinge mounts to.

Cleaned off the excess and sprayed it.

And we've been doing some filler work which is very nearly complete, so hopefully it should be in primer in a couple of weeks.

Then I remembered that it would be a good idea to check the seam strips which the fronts didn't fit that well. So I wire brushed them, fitted them on and clamped the down, made slot in a bit of oak with a curve at the back so it wouldn't damage the curve of the strip and gave it a few hit's with the hammer which they know fit  (no pics

(no pics  )

)

Any one know what this sticker is? it was on the passengers side B post just below the door catch.

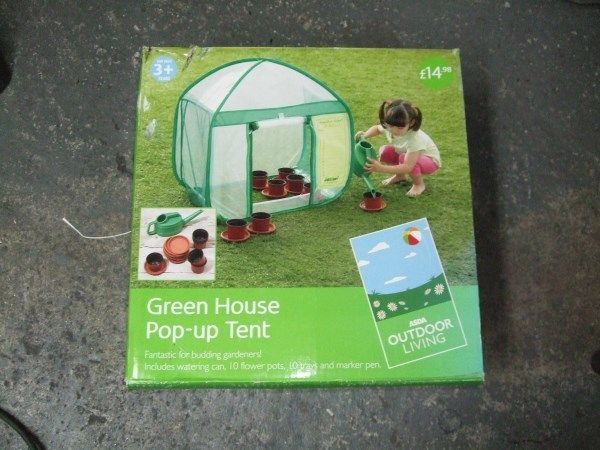

Ooo and got a nice box of goodies, mainly panels for the RSP, but other bit's like bumpers, cam, pistons and exhaust. and got some DSN stuff's

Other than cleaning off the inside floor and spraying it with u-pol zinc primer, Thats all the things I can remember I've done/ got pics of, but it's moving along. I'm hoping to have it ready for riv run and maybe London to Brighton. A mate of mine bet that I won't get it done by the end of the year, I'm trying to decide what I'm going to spend my winnings on  .

.

![]()