Great stuff Alex, coming along nicely

Alex's 1982 Hle Rebuild

#376

Posted 08 December 2014 - 08:48 AM

#377

Posted 09 December 2014 - 09:19 PM

Great stuff Alex, coming along nicely

Cheers Mate ![]()

#378

Posted 09 December 2014 - 10:01 PM

looking sweet man!

seems like everybody can weld except for me haha ![]()

#379

Posted 09 December 2014 - 10:15 PM

looking sweet man!

seems like everybody can weld except for me haha

cheers Chris, Anybody can do it, just takes a bit of practice ![]()

#380

Posted 13 December 2014 - 09:22 PM

Got a couple of bits done over the past few days, I started with the petrol tank holder bracket. Started wire brushing the area ...

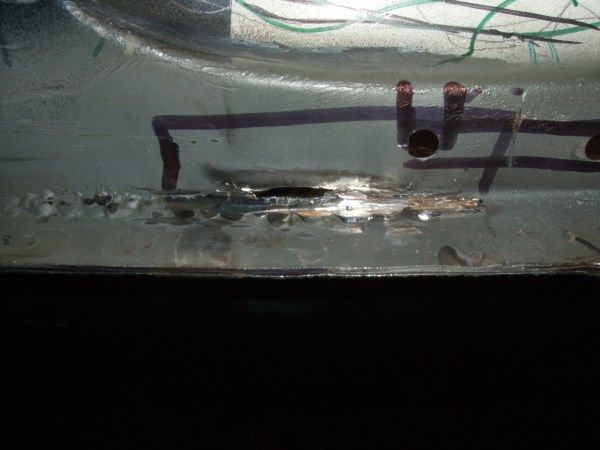

Which ended up with this being cut out and welded in.

And welded the bracket on, Hopefully it's in the right place.

Then I fished drilling the shock stregtheners and welded them in.

Got the headlamp rings welded on and also welded the holes where the grille fitted previously.

Then we knocked this up out of 2 pallets and the caster wheels we had.

So we lowered the shell down bit by bit until it was the right hight to be rolled over onto the mattress.

And I got a parcel ![]()

#381

Posted 13 December 2014 - 11:31 PM

#382

Posted 14 December 2014 - 08:24 AM

Early Christmas present there with that parcel!

#383

Posted 14 December 2014 - 10:07 AM

With that patch you did for the fuel tank bracket, what did you use to cut the metal? because I'm struggling to get into small areas with the angle grinder.

For the horizontal cut I used a normal grinder and cutting disc and for the vertical cuts I used some of the dremel type small cutting discs ( about 1" diameter) in a drill. once you cut through the metal you can fit a hacksaw blade and use that to cut it.

Early Christmas present there with that parcel!

Haha, yep feels like santas been already, just that I knew what it was and I had to pay for it ![]()

Edited by alex-95, 25 December 2014 - 10:04 AM.

#384

Posted 14 December 2014 - 05:38 PM

Nothing wrong with buying yourself a present mate

#385

Posted 14 December 2014 - 08:05 PM

With that patch you did for the fuel tank bracket, what did you use to cut the metal? because I'm struggling to get into small areas with the angle grinder.

[/quote]

For the horizontel cut I used a normal grinder and cutting disc and for the vertical cuts I used some of the dremel type small cutting discs ( about 1" diameter) in a drill. once you cut through the metal you can fit a hacksaw blade and use that to cut it.

Ok cool. Thanks I'll have a look online. Is that in a normal drill or in a Dremel type? Sorry for the questions. I've been doing bits on on my mini for years but haven't really done any bodywork. Used my new welder for the first time last week 😱

#386

Posted 14 December 2014 - 08:19 PM

[quote name="Mini_Matt" post="3185756" timestamp="1418513473"]

With that patch you did for the fuel tank bracket, what did you use to cut the metal? because I'm struggling to get into small areas with the angle grinder.

For the horizontel cut I used a normal grinder and cutting disc and for the vertical cuts I used some of the dremel type small cutting discs ( about 1" diameter) in a drill. once you cut through the metal you can fit a hacksaw blade and use that to cut it.

Ok cool. Thanks I'll have a look online. Is that in a normal drill or in a Dremel type? Sorry for the questions. I've been doing bits on on my mini for years but haven't really done any bodywork. Used my new welder for the first time last week

It was just with a corded drill on the fastest setting, it would have been a lot easier with a dremel (or an air type one which I didn't think about ![]() ) as the drill is a bit bulky, thats why there is a slight angle to them. How did the welding go?

) as the drill is a bit bulky, thats why there is a slight angle to them. How did the welding go?

I spent my day scraping off the underside today.

I've got a half day on thursday so hopefully I'll get the boot and toeboard scraped off and start wire brushing.

#387

Posted 14 December 2014 - 09:47 PM

#388

Posted 15 December 2014 - 08:24 PM

My dad's got a Dremel so get some bits for it. I bet that job is a little tedious...yeah the welding went alright I have a couple of patches to do before an mot. But I've got the helmet that doesn't auto darken so I'm basically blind till I pull the trigger! lol

That'll be easier then, yeah was a bit mainly on the tunnel. Ah right, the auto darkening helmets makes welding a hell of a lot easier.

#389

Posted 21 December 2014 - 09:52 PM

looking good Alex, rust treatment next.....

#390

Posted 31 December 2014 - 10:16 PM

looking good Alex, rust treatment next.....

Cheers minimuk, Yep, got some abrasive discs to go on the grinder so hopefully that'll make light work of that.

Before christmas I finished weleding the rear valance on, the closures needed to be clamped to the valance curve, I first done this with a normal clamp but that left a small dent so way back in the build thread when I was making version 1 closures we cut out a peice of wood to the curvature of the valance and luckily I kept it so pulled that off the work bench got a bit clamp can clamped it together with no marks (just the smell of burning wood)

like so:

we then ground down all the welds on the valance and closures, I have a couple of places to reweld.

stripped down the front subframe and found this in the trumpet/cone. seems like it was a fix for a stripped thread?

Theres some pitting on the boot floor area so cut out this bit and welded in a new bit.

I cut out a rust bit on the sill and made a couple of patches for it so will get them weled on tomorrow and grind down the welds on the front bumper lip.

3 user(s) are reading this topic

0 members, 3 guests, 0 anonymous users