As of today it is almost complete apart from front and rear glass. But I will start at the begining.

In November 2010 I was looking for a project to have a go at. It had to be a fairly good to starter, because as I eluded to above I can't weld or paint. What I found was this very original 1973 Leyland mini. At this time in Australia even though they had the Clubman front the clubman name was dropped, being sold as a Leyland mini.

As you can see the Australian mini had front quarter windows and flush door handles with burst proof locks and the rear window and side flipper windows remained the same size as the MK1's.

The interior was also in pretty good condition after 38 years of use.

The plan as this point was to totally strip it, recondition the mechanicals, soda blast the shell and respray it to look like the australian version of the 1275GT, which was called the Clubman GT in Australia. I'm led to believe that the Clubman GT was a result of the end to the round nose Cooper S, and all of the Cooper S parts used in the GT. I'm certainly not an expert on the history, but it went something like that.

My intial intention was to source a 1275 engine to go with the look, but as I found out the 1275 is getting scarce in Aust. and expensive. So decided to sick with the 1098, which kept the engine and chassis numbers original and matching the log books.

The next job was to start stripping it and keep fingers crossed that there wasn't to much rot.

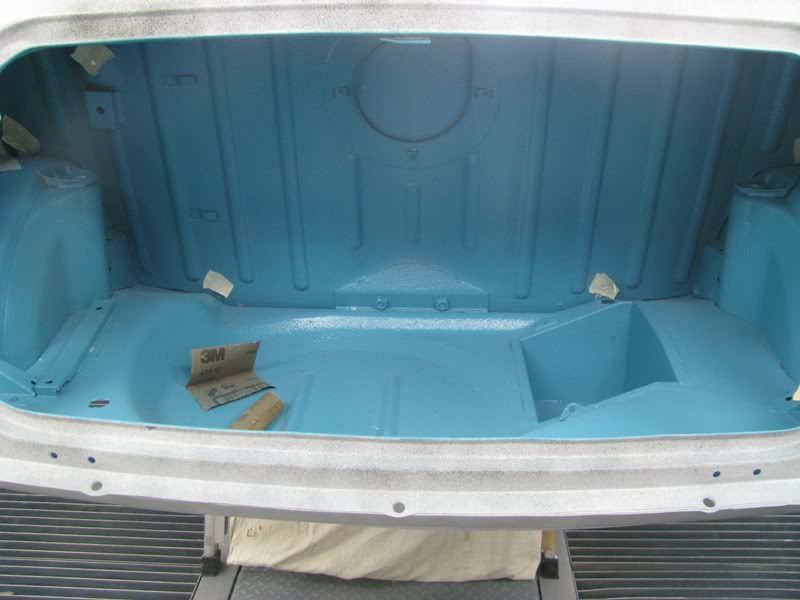

Surprisingly the floor was great!

Once stripped off it went to the Soda Blaster.

More to come.