excelent Job! I read your post on a Chilean forum and all your problems with a chap right there....at the end of the day the work on your pick up is awesome!

My 75 Mini Pickup Project In Bolivia

#61

Posted 05 December 2015 - 06:59 PM

#62

Posted 06 December 2015 - 06:55 PM

Brilliant

#63

Posted 06 December 2015 - 07:00 PM

So much skill shown and no new panels it is a credit to all involved. Just goes to show what can be done with imagination and talent. So impressed

Edited by David128, 06 December 2015 - 07:00 PM.

#64

Posted 06 December 2015 - 08:21 PM

#65

Posted 30 December 2015 - 07:26 PM

Very nice looking project indeed

#66

Posted 04 July 2017 - 11:59 PM

Did a few small things to it:

Made a vinyl cover for the bed

Put an oil temperature gauge in the transmission

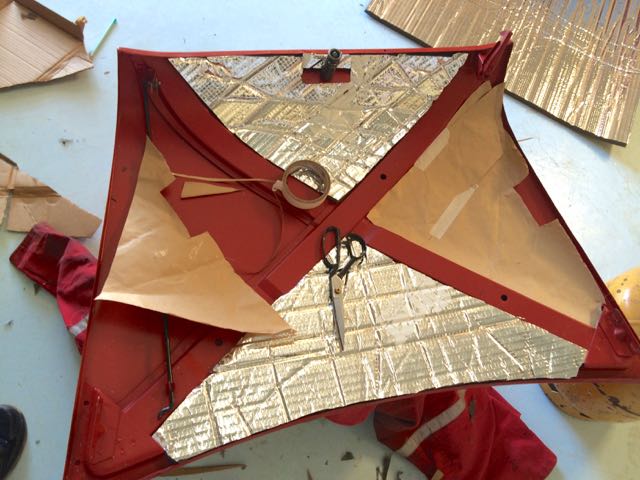

Lined the hood/bonnet with Dynamat hoodliner to cut the engine noises

And a skid plate, after replacing the flexible coupling on the exhaust and cutting the exhaust shorter to raise it.

adding a fuel pressure regulator

#67

Posted 05 July 2017 - 12:50 PM

You really need to get more overlap in any joins than that, weld is weaker than pressed and rolled steel sheet.

Is this true ? I'm starting to worry about my car now !

#68

Posted 06 July 2017 - 07:22 AM

#69

Posted 06 July 2017 - 12:58 PM

Weld thins, by the surface tension pulling the melted material in to the bead, and anneals the metal it's joining. A thicker, more rigid, bead is also a stress riser. Welding is still going to be stronger than many other ways of sticking components together, but joints should be designed accordingly - look at any production car and you'll see the joins are dispersed with maximum overlap.

3 user(s) are reading this topic

0 members, 3 guests, 0 anonymous users