Leyland Mini 1000 1980 Restoration Project

#121

Posted 06 February 2012 - 09:57 PM

Hugh

#122

Posted 06 February 2012 - 10:00 PM

#123

Posted 08 February 2012 - 09:28 PM

A few more little bits done. Removed the brackets on the "C" pillar that the quarter glass catches screw to, in preparation for fitting the new rear seatbelt brackets.

The brackets will be fitted at a later date. Next I finished blending the welds on the repair I did to the bottom of the drivers rear quarter.

Then it was back on its side to finish the passengers side sill. Jacking point fitted, Heritage part 14A8375.

Then finally got the tunnel section cleaned down.

The rear of the tunnel had quite a lot of rust and so used so rust remover gel to help sort that out.

Got the welds ground down on the subframe mounting bracket of the heal board.

Then made the rear reinforcing bracket.

Then welded in place.

Thats it, only small jobs, but every little bit helps!

#124

Posted 08 February 2012 - 09:33 PM

Hugh

#125

Posted 08 February 2012 - 09:43 PM

Come and do all the welding on my Project and i will pay you in Praise ?

#126

Posted 09 February 2012 - 09:48 PM

Graham

#127

Posted 10 February 2012 - 02:13 PM

dom

#128

Posted 10 February 2012 - 07:29 PM

Andrew thanks, praise is good but I prefer those bits of paper with numbers in the corner!!

Hi Graham, mini may look neat and tidy but you should see the garage!!

Hi Dom, the rust was pretty deep in places but I use Hammerite Rust Remover Gel. There may be better products but this works well for me. Paint on over rust and I usually leave for 30mins then scrub with wire brush a bit and then leave the gel to work over night. Will dry up and go crusty. Then wire wheel off and repeat as needed.

#129

Posted 14 February 2012 - 08:18 PM

#130

Posted 17 February 2012 - 09:40 PM

Finished welding the bottom of the passenger's inner wing.

The passenger's inner sill with all of the components welded in.

General view of the floor.

Bit of seam sealer to help keep the water out.

Then gave the inside several coats of paint.

The passenger's outer sill, Heritage 14A9535, was then fitted...

And welded in.

Spot welded along the door step seam.

I placed a piece of gaffa tape along the bottom of the rear quarter panel, to prevent arcing out and burning holes, should the side of the spot welder electrode decide to touch the metal.

Finally welded on the reshaped slinging bracket that I made earlier.

Thats it for another update.

Thanks.

#131

Posted 17 February 2012 - 10:14 PM

Graham

#132

Posted 17 February 2012 - 10:23 PM

#133

Posted 17 February 2012 - 10:42 PM

Hugh

#134

Posted 24 February 2012 - 10:19 PM

Then welded back on the battery cable channel that I removed to clean.

Then started on the rust at the bottom of the bulkhead.

Repair piece.

Welded in.

End repair.

Middle section repair.

I'll add the rest soon.

Thanks.

#135

Posted 25 February 2012 - 09:07 PM

Cut the other side out and removed the rust.

Made another repair piece.

Welded in.

This next part has the bolts for the accelerator pedal, but as they were in a resonably good condition, I cut below them.

Small repair piece.

Welded up.

Ground down and cleaned up the toe board ready to refit the steering rack bracket.

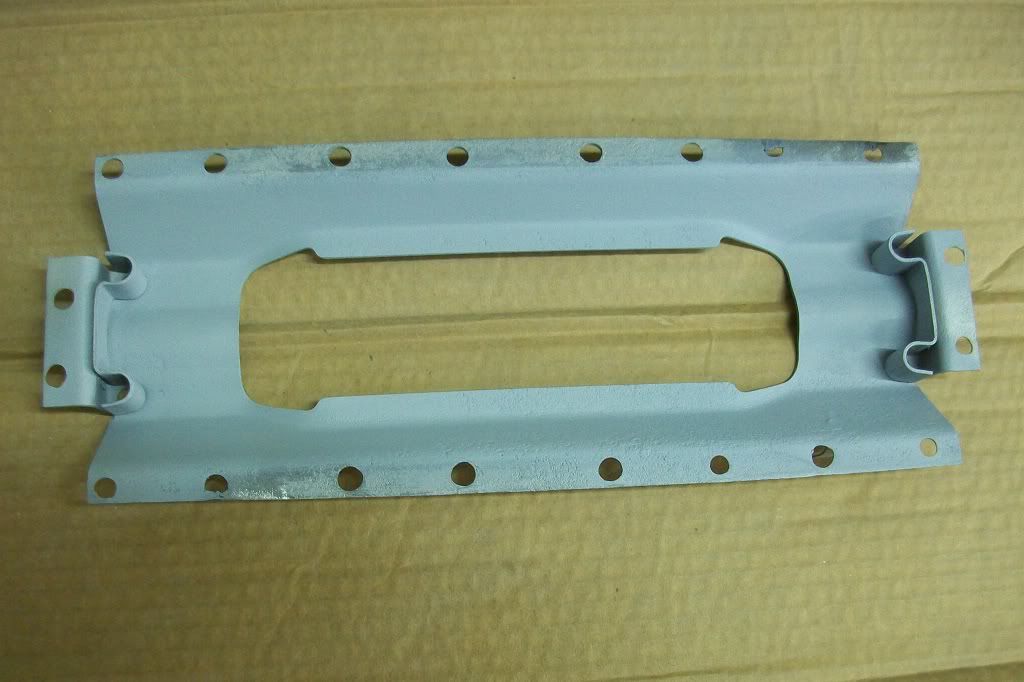

Steering rack bracket cleaned up.

I then bolted it back in place, ready to weld up through the holes I had drilled, to remove the old spot welds.

Thanks

3 user(s) are reading this topic

0 members, 3 guests, 0 anonymous users