Leyland Mini 1000 1980 Restoration Project

#46

Posted 10 November 2011 - 10:16 PM

#47

Posted 11 November 2011 - 10:57 AM

Its great to see it all going well with lovely new metal!

ganna be great when its done!

it must feel good looking at it now to when you first started pulling it apart!

#48

Posted 12 November 2011 - 09:08 PM

#49

Posted 12 November 2011 - 09:59 PM

#50

Posted 15 November 2011 - 10:18 PM

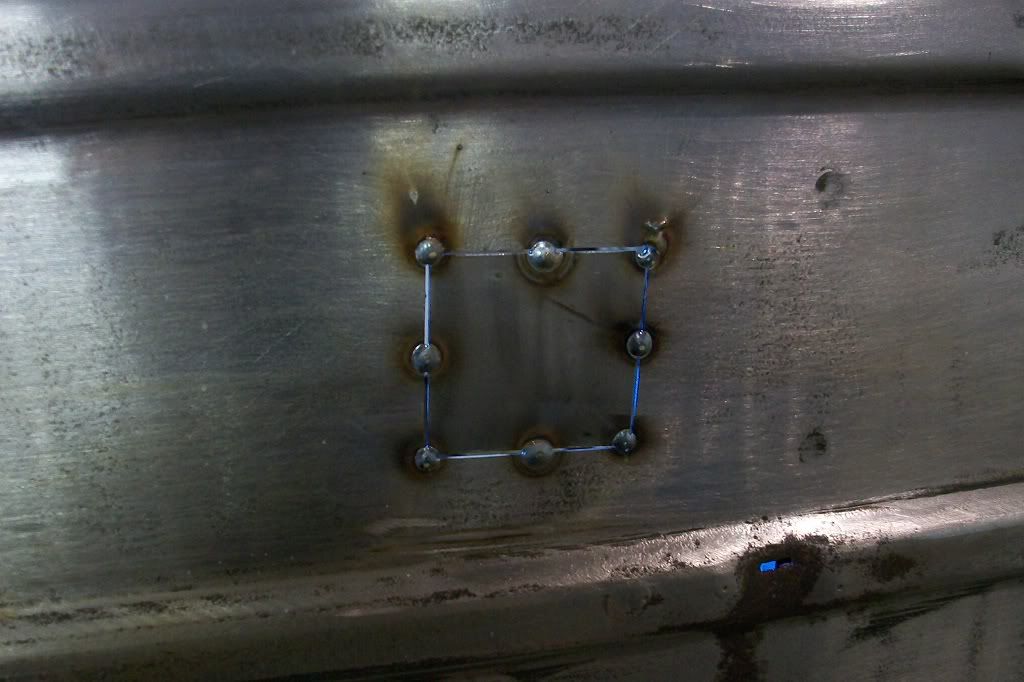

Ok, another update but a bit of a boring one i'm affraid. A few more bits to finish off the right hand half and one of the holes in the floor had some rust around it. As it was not needed a decided to fill this one.

A square was cut and welded in.

And cleaned up.

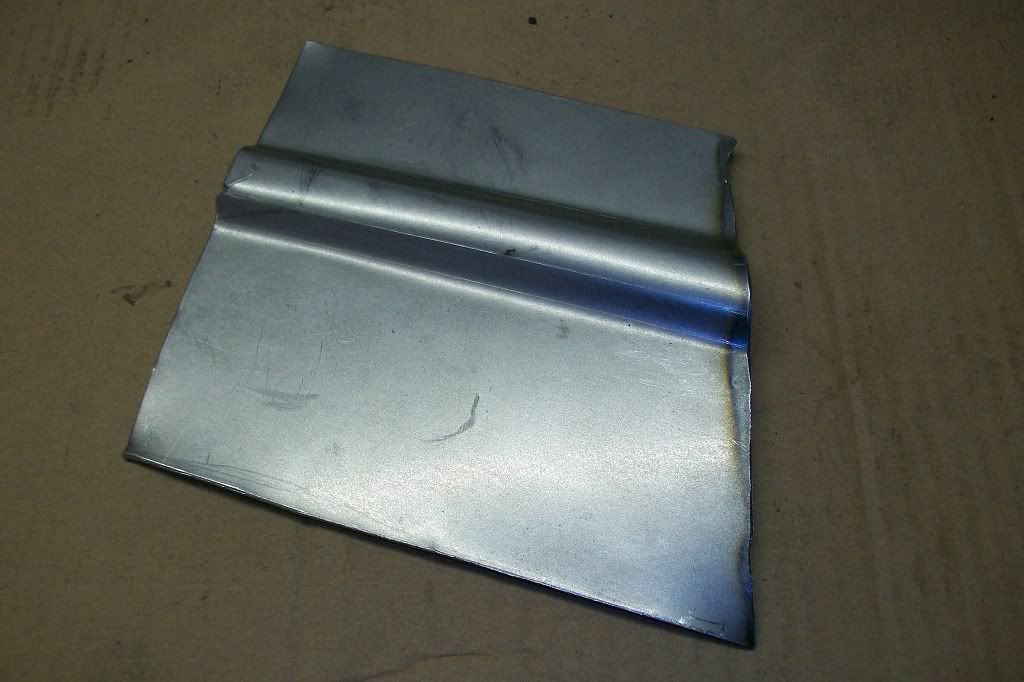

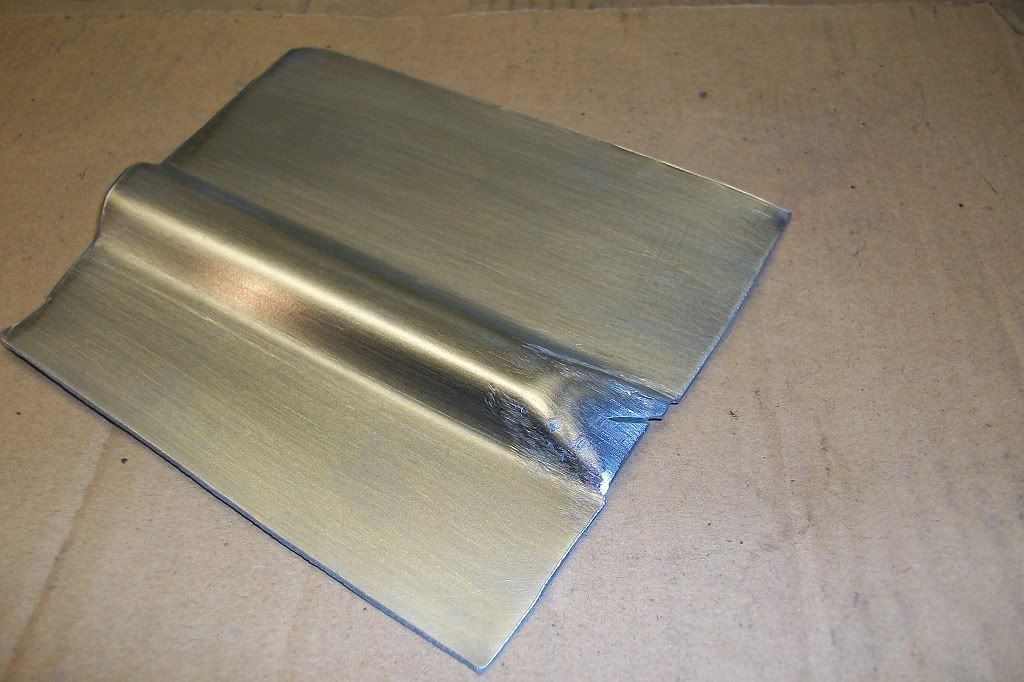

The inner sill came with the front slinging bracket already fitted, but I had to remove it as the join between the inner sill and the foot well panel, ran underneath it. I wasn't quite happy with the shape of it anyway compared to the original and as Heritage ones were on back order at the time I decided to remake it. I flattened out the bracket with a big hammer and refolded it in the vice and am quite pleased with the results.

Slinging bracket removed from inner sill/floor.

Remade bracket.

New bracket compared to original.

The bracket was then welded to the floor.

New Heritage fuel and brake pipe multiclip ALA5527 was then welded in place.

Three Heritage fuel and brake pipe clips ALA5536 were also welded on to replace the rusty old ones.

I then removed the right hand rear wheel arch and made a repair piece for the lower corner of the rear quarter panel.

Welded in, cleaned lipped edge of panel down and primed with zinc rich weld through primer.

Prepared the new wheel arch (again Heritage 14A9558), drilled for plug welds and zinc primed.

Here you can see the bar I made up before removing the arch to help align the new arch. Bolted through the rear damper hole.

Welded in. You can also see the closing panel welded in at the front of the arch, 14A6611.

Rear quarter corner repair cleaned up a little.

Floor cleaned down to bare metal and etch primed to protect from the damp.

Thats the right side done, sorry I didn't have as many photos of before shots as I thought.

Thanks for looking.

#51

Posted 16 November 2011 - 07:32 AM

#52

Posted 17 November 2011 - 07:14 PM

#53

Posted 19 November 2011 - 11:38 PM

#54

Posted 22 November 2011 - 10:08 PM

Thanks mate.

#55

Posted 22 November 2011 - 10:15 PM

I'm afraid Erm wont be appearing at Stamford now as we are moving done south in January. It would have been nice to have taken him to the show.

Neil

#56

Posted 22 November 2011 - 10:56 PM

#57

Posted 22 November 2011 - 11:34 PM

Thanks for the comments Frik and thanks Neil.

#58

Posted 23 November 2011 - 09:05 PM

Nice hole in the passengers footwell.

Another oversill with some messy welding.

Peeled back the oversill to reveal this!

This gives some idea of when they were fitted. Dated 7.10.96 which would be about right as it was last on the road in 1999.

With oversill removed there's not a lot left!

I cut the inner sill/floor out between the first and second grooves, but sorry no picture and found the end of the second groove needed some repairs, so cut it out.

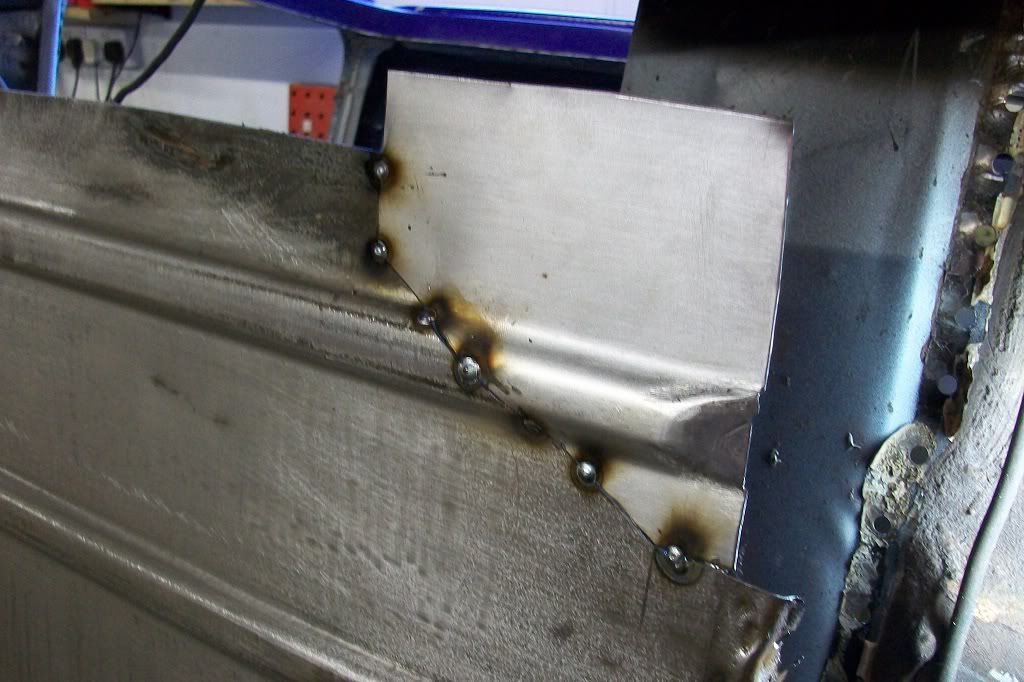

Made this by folding in a vice.

Cut and tacked in place.

Then started on a repair piece for the floor to heal board joint. Will add pictures of that soon.

Thats it for now. Thanks.

Edited by minifcd, 23 November 2011 - 09:14 PM.

#59

Posted 26 November 2011 - 04:41 PM

Tested for fit against the new heal board.

Clamped, tacked and welded in place.

Next the lower rear corner of the companion box needed a repair, so folded a small piece and clamped in place.

Tacked then fully welded.

Ground down.

The finished piece.

Thanks.

#60

Posted 26 November 2011 - 04:57 PM

Hugh

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users