Leyland Mini 1000 1980 Restoration Project

#331

Posted 19 December 2012 - 11:14 PM

must update my thread......

#332

Posted 20 December 2012 - 08:55 AM

attention to details is amazing!

looking forward to see this finished!

#333

Posted 24 December 2012 - 01:14 PM

Good idea about the stainless bolts by the way that would finish it off really nicely. I might steal that idea if make the internal brackets.

Cheers Ollie

#334

Posted 07 January 2013 - 10:50 PM

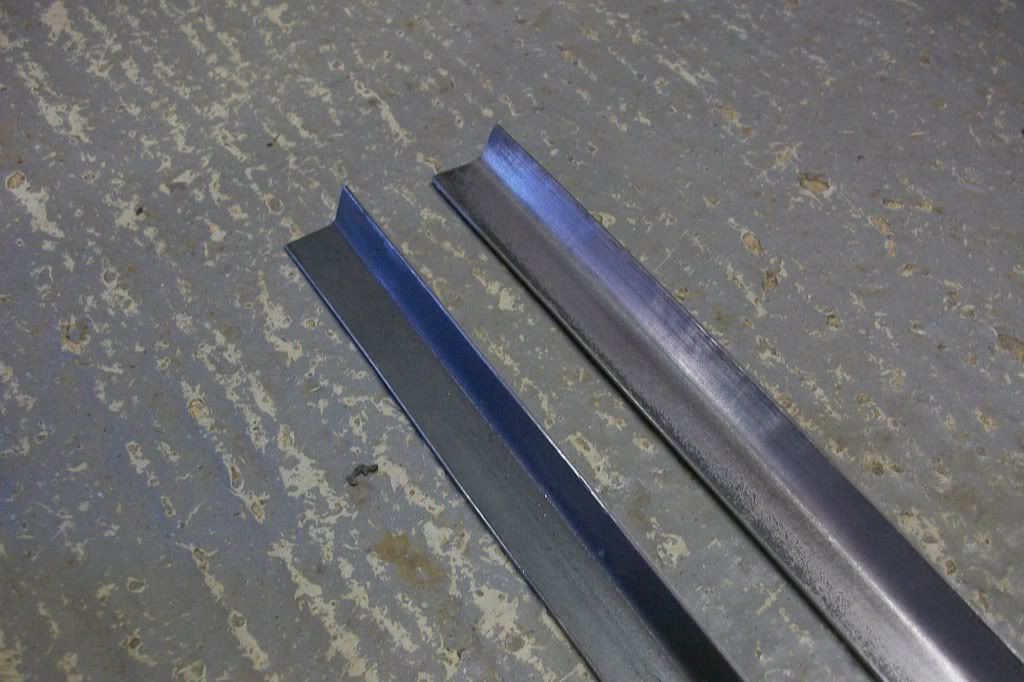

Made these two strips of metal to reinforce the seat front. I had to make them as two pieces, as I didn't have a piece of metal long enough and could only fold upto 600mm in length anyway.

Made from 1.5mm steel and folded to approximately 120 degrees.

Spot welded on.

Slightly thicker steel than the one that was on the old floor/seat pan, so should be that little bit stronger.

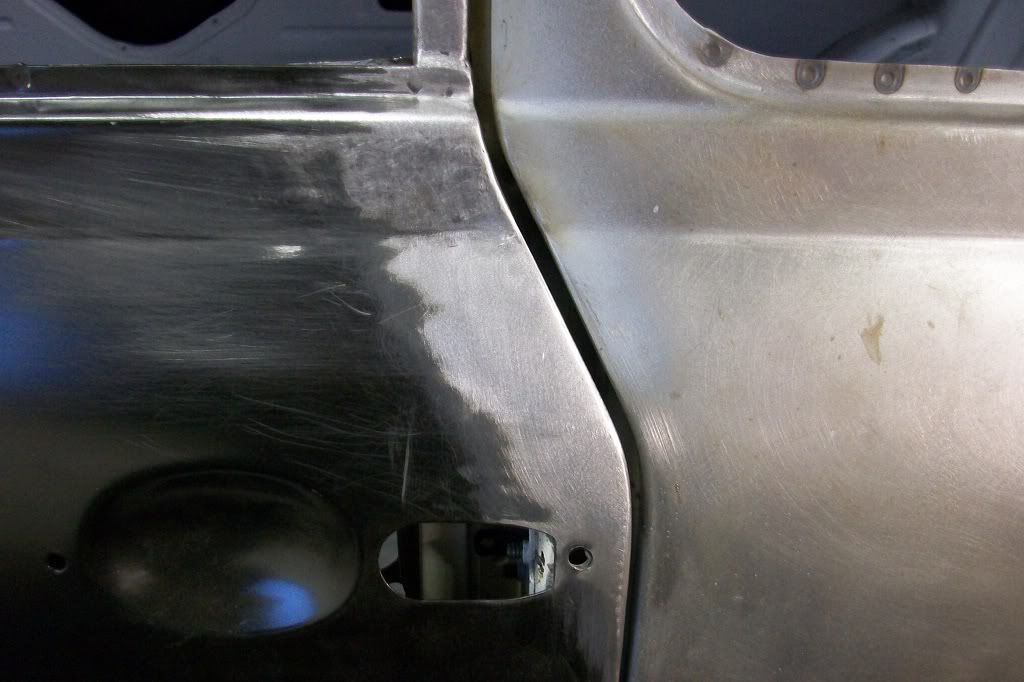

Passenger's A panel and door gap sorted.

Rear edge of the door had a large gap, just like the driver's side.

Built up some weld along the edge.

Ground down.

The finished door and gaps.

Thanks for looking guys. I will have some more interesting stuff to upload shortly when I get time.

#335

Posted 07 January 2013 - 10:56 PM

Great gaps you've achieved on the door hmm not looking forward to doing that on mine

Regards

Clifford

#336

Posted 07 January 2013 - 11:20 PM

#337

Posted 07 January 2013 - 11:21 PM

And Clifford, it's easy with external hinge doors, Just file the doors till it fits nice!!

#338

Posted 07 January 2013 - 11:51 PM

I hope to start again soon on Evy, to much going on at the min

#339

Posted 08 January 2013 - 12:42 AM

#340

Posted 12 January 2013 - 12:13 AM

Pete

#341

Posted 25 February 2013 - 01:17 PM

#342

Posted 25 February 2013 - 08:38 PM

Hugh

#343

Posted 25 February 2013 - 11:17 PM

Thanks Hugh. Sorry for the lack of updates recently but haven't had any free time. It'll all kick of again soon though and then I can crack on with mini project No.3!

#344

Posted 15 June 2013 - 07:33 PM

Any updates on this ?, miss your clean work and heritage shine ![]()

Cliff

#345

Posted 17 June 2013 - 10:21 PM

Hi Cliff. Sorry for the major lack of updates in the last 6 months, but I have had no time to do anything other than cleaning and painting a few small parts. However, I have had a few people ask about updates and so I have got next week off work with the aim to get the shell finished and ready to go for paint. I also have a few other photos of bits and bobs I've done that I'll try to get uploaded soon. Thanks for your interest.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users