Leyland Mini 1000 1980 Restoration Project

#286

Posted 08 July 2012 - 07:48 PM

Matt

#287

Posted 08 July 2012 - 09:22 PM

Thanks

#288

Posted 09 July 2012 - 06:15 PM

#289

Posted 09 July 2012 - 06:22 PM

Havn't been here for some time - that door repair is to your usual extreme standard which makes me feel so amateur. Great!

Hugh

#290

Posted 13 July 2012 - 08:58 PM

#291

Posted 09 August 2012 - 08:58 AM

Got a thin skim of filler on the bottom of the door to tidy it up and then primed.

Then I realised I hadn't put the drain holes back in! So using what was left of the old door bottom as a guide, I measured and drilled them to roughly the same positions.

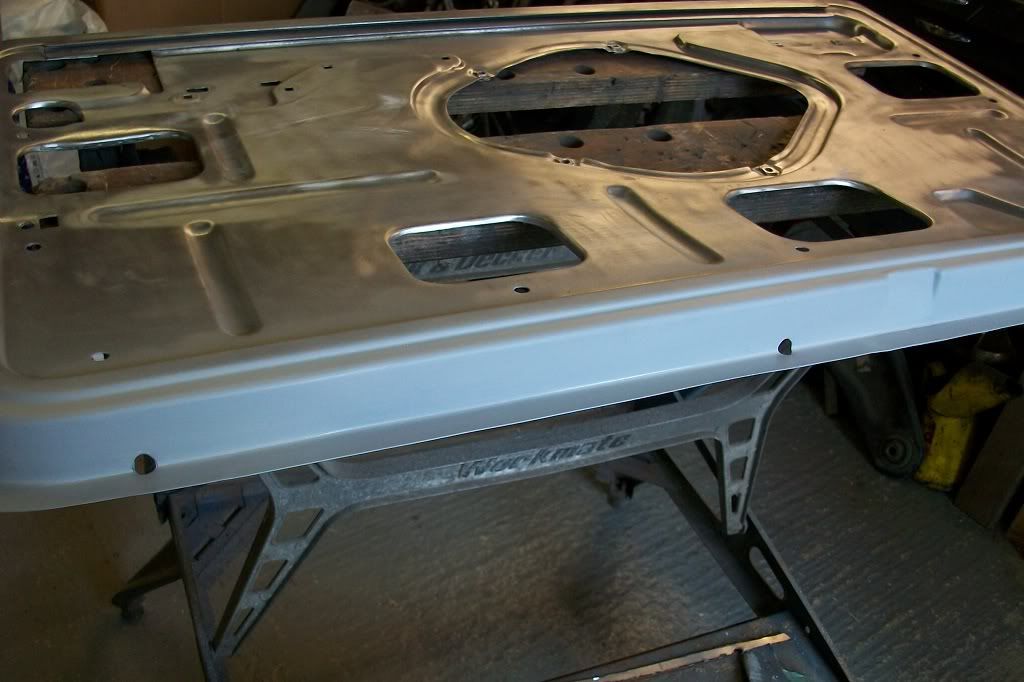

Primed and painted the inside of the door frame and then trial fitted the frame to the shell.

A minor bit of welding was needed to the check strap mount on the inside of the door frame, but once happy, I started to fit the skin (CZH3301 Heritage).

The door initially fitted quite well but had to spend the best part of an hour shimming the door hinges, tweeking and adjusting to get the gaps about right. Needs some work at the top of the A panel as the gap is a bit small, but at least one skin is on!

Starting to tackle the drivers door now. That looks like even more fun!

Thanks.

#292

Posted 09 August 2012 - 07:28 PM

Hugh

Edited by hughJ, 09 August 2012 - 08:43 PM.

#293

Posted 09 August 2012 - 08:24 PM

now don't wait for another month....

#294

Posted 09 August 2012 - 10:47 PM

Started stripping the other door down to the bare frame.

Unfortunately someone had been here before and had done a "running repair" to keep it going. Piece of angled steel tacked on and a lower door skin repair had been added.

The rust had caused the folded lip of the skin to swell to nearly half an inch thick and had completely rotted the lip of the frame away.

The other corner was constructed from 50% filler and 50% rust!

Got the skin cut off and it soon became obvious that the frame would need extensive repairs to the bottom, both corners, and both sides nearly to the top.

Although it could be repaired (eventually), I wanted a quicker outcome, so looked through my "stock" for a better frame and found this one with the skin already removed. This too had seen an attempt by someone to repair it at some point, but was in a much easier state of repair.

I will remove this previous repair and make a new piece to make use of this door instead.

Thanks all, more repairs to do tomorrow!

#295

Posted 10 August 2012 - 11:04 PM

#296

Posted 15 August 2012 - 09:09 PM

Used the repair piece I made as an example in an earlier update, to repair the curved corner.

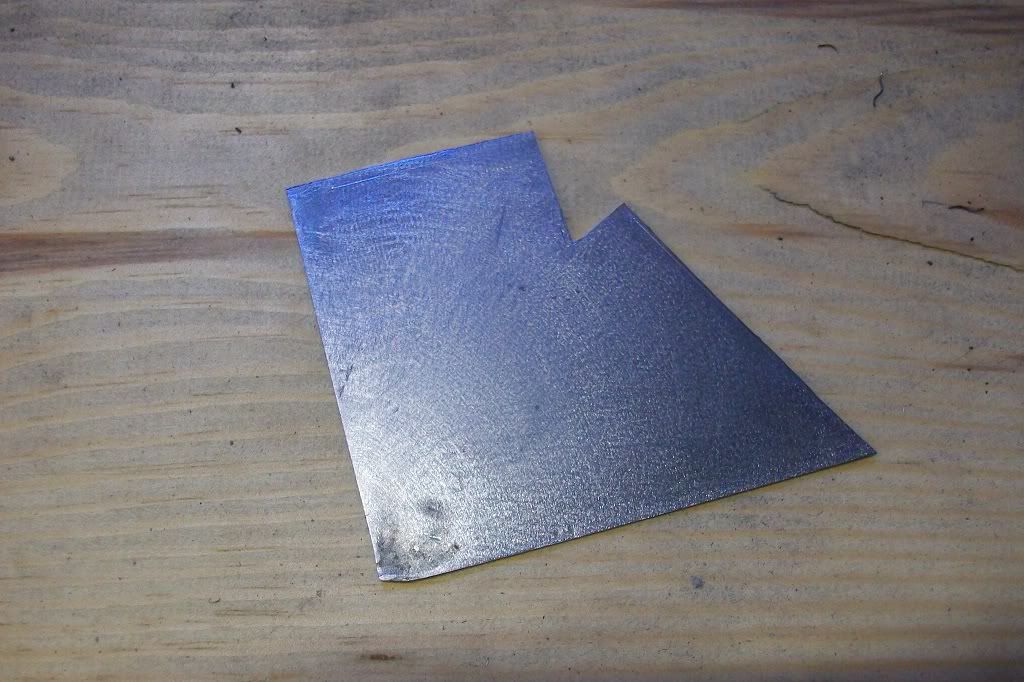

Straight piece made (folded in a metal folder).

New repair piece made for the front "square" corner of the door. Much harder to make than the curved piece, as the extra metal makes it harder to stretch when forming.

Tacked in place. Fits quite well.

Found quite a few cracks in the frame around the hinges, so drilled the end of each crack and welded up.

Repairs to the side lip. All the repair pieces were made from the metal of the old door skin. Keeps the costs down and recycles good metal!

The door frame repaired! I even remebered to put the drain holes in this time!

Just need to fit the skin now.

Thanks.

Edited by minifcd, 15 August 2012 - 09:54 PM.

#297

Posted 15 August 2012 - 09:54 PM

Graham

#298

Posted 15 August 2012 - 10:31 PM

#299

Posted 16 August 2012 - 08:06 PM

Hugh

#300

Posted 01 September 2012 - 05:47 AM

Thanks a lot m8, you have just sorted my problem for me....Thanks Hugh.

A little more progress. Rear quarter panel cleaned down to bar metal.

Then, whilst cleaning around the "C" pillar, I found this little hole.

Made another repair piece.

Trimmed and tacked in place.

Welded up.

Cleaned down.

Then had to do the same to the rear panel upper corner.

Small piece made and tacked in.

Welded up.

Finally, ground down.

Thanks for looking.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users