Leyland Mini 1000 1980 Restoration Project

#271

Posted 24 June 2012 - 10:18 PM

Graham

#272

Posted 26 June 2012 - 10:40 PM

Trace the shape you need onto some metal and add about 1/4 inch onto the inside of the bend. Don't add too much as it gets too hard to work with and too little leaves you with nothing to weld to.

Using vice grips, start folding up along the line.

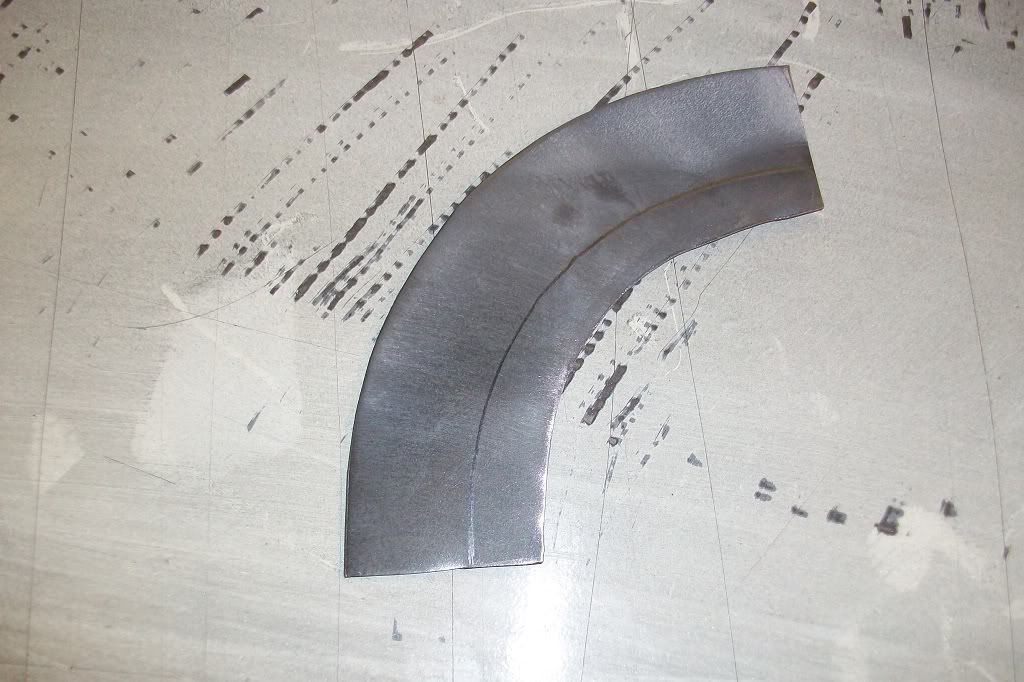

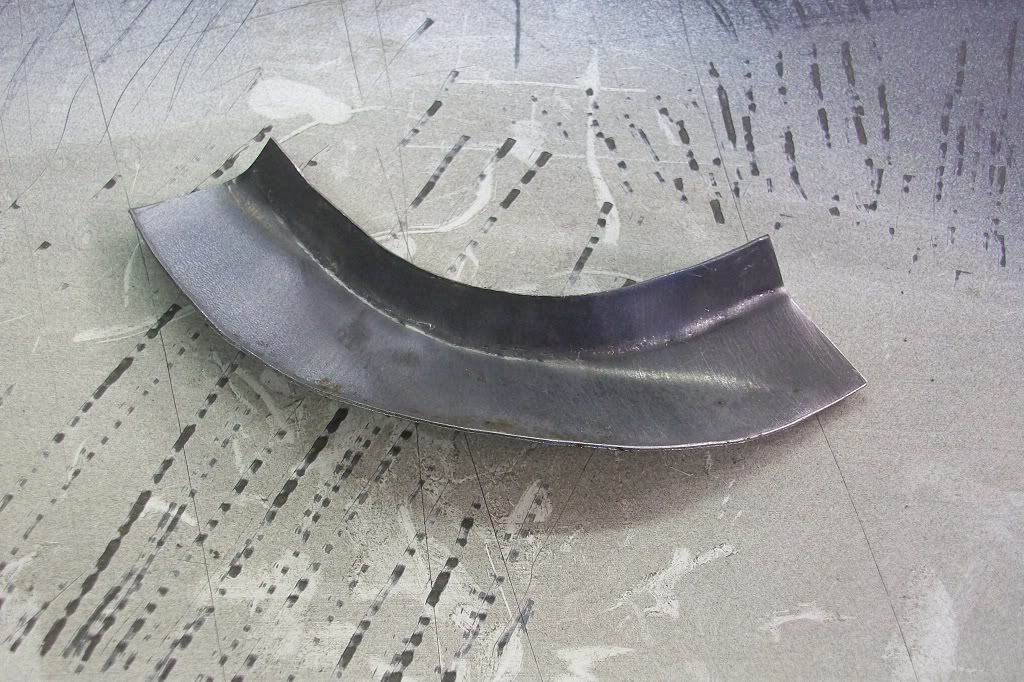

It begins to look like this.

The more you fold, the more the metal distorts.

So to straighten it out, you then need to stretch the metal using a small cross pein hammer, against a larger hammer in the vice. As you hit it, the metal stretches and starts to straighten.

Then use the flat end of the hammer with lighter blows to help remove the marks made.

Repeat the above on the larger side until the distortion has gone and the correct shape returns. Should then look like this.

Takes about 20 minutes and should end up something like the bit that needs replacing.

Hope that all makes sense.

Thanks.

Edited by minifcd, 26 June 2012 - 10:44 PM.

#273

Posted 26 June 2012 - 11:52 PM

Edited by Brams96, 26 June 2012 - 11:52 PM.

#274

Posted 27 June 2012 - 07:17 AM

#276

Posted 27 June 2012 - 09:09 PM

#277

Posted 27 June 2012 - 09:33 PM

well done

#278

Posted 27 June 2012 - 09:41 PM

#280

Posted 28 June 2012 - 12:46 PM

by the way how did you strip all the paint from your door, looks really clean instead of little bits still there or dull.

thanks, dom.

#281

Posted 28 June 2012 - 07:28 PM

#282

Posted 30 June 2012 - 04:35 PM

Did the larger areas first with the clean and strip disc on the angle grinder. Then got into the harder to get to bits with paint stripper. Painted it on and when the paint blistered, attacked it with one of the small black wire brushes that look like a toothbrush. They're relatively soft compared to a large wire brush. Paint comes off really easily. Just gotta clean the metal down thoroughly afterwards to remove any traces of paint stripper.

sweet, thanks man.

dom

#283

Posted 30 June 2012 - 04:50 PM

#284

Posted 04 July 2012 - 12:15 PM

I do have one question and you seem the perfect person to ask and it might be frowned upon by some...my apologies to any purists out there....I have a Mk3 Japanese import with the Mk1 rear/ boot, external hinges, front end and full Mk1 interior to seats, switches, high low dip botton on the floor but needs a full strip and refurb. My question will be the complexity to remould the doors to those of the Mk1 with the curvature in the corner? I have looked at Plastics4performance for the windows but was wondering after seeing your thread about your views of altering the Mk3 doors??

The guy who had my little car before seems to have gone to an amazing length to where it is and want to try and continue it to fruition...if possible??

Anyway please, as said earlier, keep up the posts!!

#285

Posted 08 July 2012 - 11:19 AM

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users