Leyland Mini 1000 1980 Restoration Project

#241

Posted 06 May 2012 - 07:44 AM

Graham

#242

Posted 06 May 2012 - 09:24 AM

#243

Posted 06 May 2012 - 10:31 PM

So ground down the inside of yesterdays repair first.

Then sorted the final bit on the passenger's side front corner.

Final piece made up and welded in.

Gutters all done, at last!!

Thanks

#244

Posted 06 May 2012 - 10:35 PM

#245

Posted 07 May 2012 - 12:00 PM

Chris

#246

Posted 07 May 2012 - 05:17 PM

#247

Posted 08 May 2012 - 05:23 AM

#248

Posted 08 May 2012 - 06:09 PM

Cheers mate

Matt

#249

Posted 08 May 2012 - 06:34 PM

Hugh

#250

Posted 08 May 2012 - 06:34 PM

#251

Posted 08 May 2012 - 07:57 PM

#252

Posted 14 May 2012 - 03:08 PM

I reckon there will be loads of folk bookmarking this thread for reference on their own rebuilds - I know I have! Passing on some of your techniques such as the gutter repairs will save lots of headscratching for the rest of us; thank you.

Keep up the great work Scott.

Cheers,

Steve

#253

Posted 17 May 2012 - 10:44 AM

dom.

#254

Posted 20 May 2012 - 08:26 PM

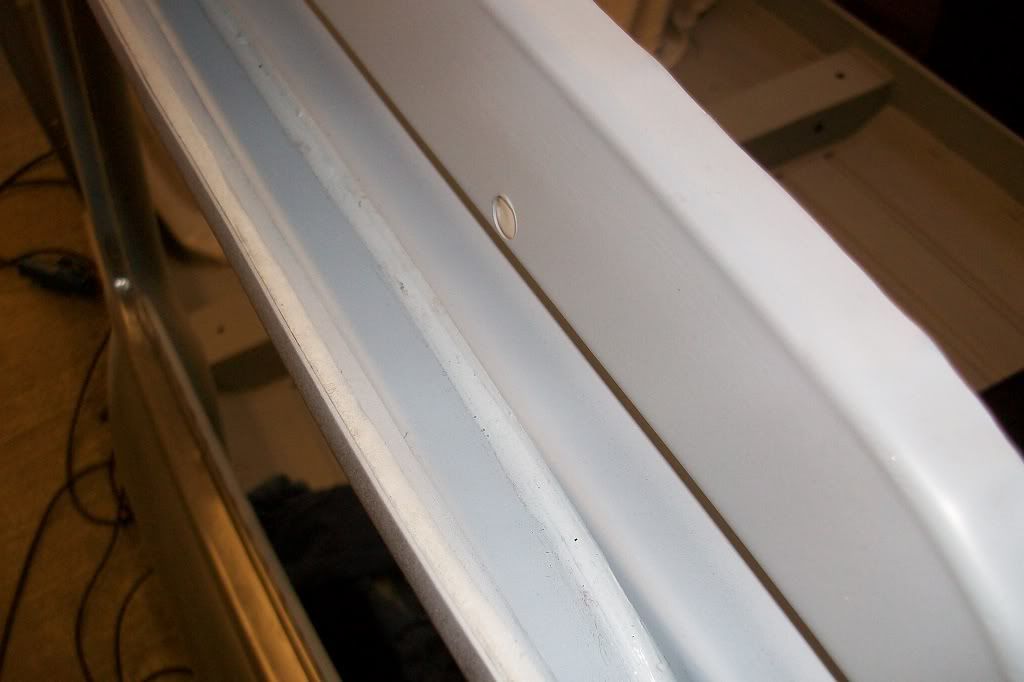

This is a mixed update from last weekend and this weekend as I didn't get time to post it last week. So last weekend I got the inner gutter lip primed with weld through zinc primer, ready to spot weld the roof on, then masked this off when dry, and flooded any seams with weld through zinc primer several times. The idea being that this will be drawn into the seam through capillary action to add some protection. Then primed the inside of the gutters with etch primer. When dry I seam sealed around the seams.

Then cleaned the e-coat off of the new waist rail edges.

Then primed and painted the inside of the waist rail where it will be hard to paint, with some grey I had lying around.

Clamped in and spot welded.

Other side done as well.

This weekend I spot welded in the C pillar seat belt brackets, Heritage ALJ360120 and ALJ360130.

Again, seam sealed behind bracket, zinc primed edges to be welded, masked off and primed and painted the back of bracket and inside of C pillar.

Spot welded in.

I've got this next week off so hope to get lots more done!

Thanks

#255

Posted 20 May 2012 - 09:19 PM

Graham

2 user(s) are reading this topic

0 members, 2 guests, 0 anonymous users