Leyland Mini 1000 1980 Restoration Project

#211

Posted 04 April 2012 - 10:12 PM

#212

Posted 07 April 2012 - 08:54 PM

Got quite a curve to this bit.

Small piece welded onto the back. I couldn't find any better way to go about this due to the way the metal curves, shrinks and stretches.

Rust chopped out.

Welded in.

That was the easy bit! Rest of afternoon spent grinding and blending it together. Worst bit so far.

Thats the drivers side and front corner all finished.

Got the other side to do and a bit on the rear left corner that I have know idea how to tackle at the moment.

Thanks for looking.

#213

Posted 07 April 2012 - 10:52 PM

#214

Posted 08 April 2012 - 08:37 PM

I was just wondering how you get your welds so flat? They almost look like puddle welds theyre so smooth! Mine seem to stick up quite high which takes an absolute age to grind down!

Regards

matt

#215

Posted 08 April 2012 - 10:51 PM

#216

Posted 09 April 2012 - 12:22 AM

#217

Posted 09 April 2012 - 11:40 AM

Scott

#218

Posted 10 April 2012 - 10:55 PM

Anyway got the inside of the gutter all ground down. I found the best tool to be my home made drill mount with a 2 mm cutting disc at a slow speed on the drill.

And for the vertical lip on the inside, the same, but with a flap disc facing towards the drill and with the drill running in reverse.

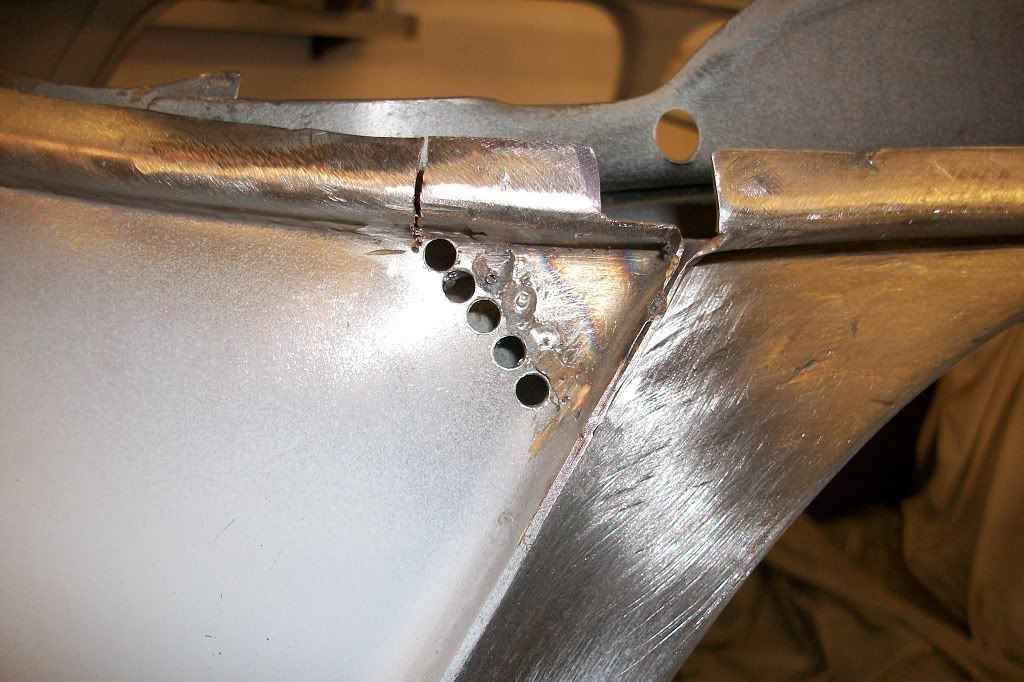

I wasn't very happy with a previous repair to the rear panel, at the C pillar, on the drivers side and it would have been hard to grind down. So chopped it out by drilling holes close together to remove it, as I couldn't get the cutting disc in.

Made a new piece, welded in and ground down.

Then finally got the shell turned around to start on the other side. Again, doesn't look too bad on outside, but rotten on inside.

Repair pieces made and tacked in.

Had to put a small piece in here.

Had to weld a bit on to the top edge of the gutter at the rear edge to build it up.

Then on to the front passengers corner. Chopped out. Used some gaffa tape to stop debris falling down the pillar.

Piece made.

And welded in.

Will attempt the big grind down next weekend if all goes well.

Thanks.

Edited by minifcd, 10 April 2012 - 10:58 PM.

#219

Posted 10 April 2012 - 10:59 PM

#220

Posted 11 April 2012 - 04:58 PM

Thanks again, keep up the good work!

Matt

#221

Posted 11 April 2012 - 08:25 PM

What sort of welder have you got?

Cheers, Paul.

#222

Posted 11 April 2012 - 08:41 PM

Paul, my welder is a Clarke 151 TE Turbo.

#223

Posted 24 April 2012 - 06:09 PM

#224

Posted 25 April 2012 - 06:09 AM

#225

Posted 25 April 2012 - 12:45 PM

2 user(s) are reading this topic

0 members, 2 guests, 0 anonymous users