Posted 19 December 2012 - 04:56 PM

Posted 22 December 2012 - 04:33 PM

Posted 23 December 2012 - 06:55 PM

Posted 24 December 2012 - 08:41 AM

Its just a case of strengthening the shell where you can by seam welding and removing any rot so you have a good strong shell. I always double skin the front floors aswell for a bit of rigidityLooks ace! I'm gonna start building my road rally mini soon, hopefully be finished in a couple of years. Any tips on shell prep?

Posted 24 December 2012 - 10:02 AM

I always double skin the front floors aswell for a bit of rigidity

Looks ace! I'm gonna start building my road rally mini soon, hopefully be finished in a couple of years. Any tips on shell prep?

Posted 24 December 2012 - 10:44 AM

That's interesting. Can I ask how you do that - do you use another pre-formed floor panel on top of the existing one, or do you just use sheet steel? If the latter, what thickness?

I read on another of the rally car builds (sorry, forget which one) that the poster welded some square tube on the junction of the floor/bulkhead to stiffen that area. Do you do that as well, or not found it necessary? (I think the other build was a stage car)

Posted 24 December 2012 - 06:36 PM

Posted 27 December 2012 - 09:04 AM

Posted 08 January 2013 - 11:47 AM

Posted 08 January 2013 - 01:22 PM

Real colour lol

Posted 08 January 2013 - 02:12 PM

Real colour lol

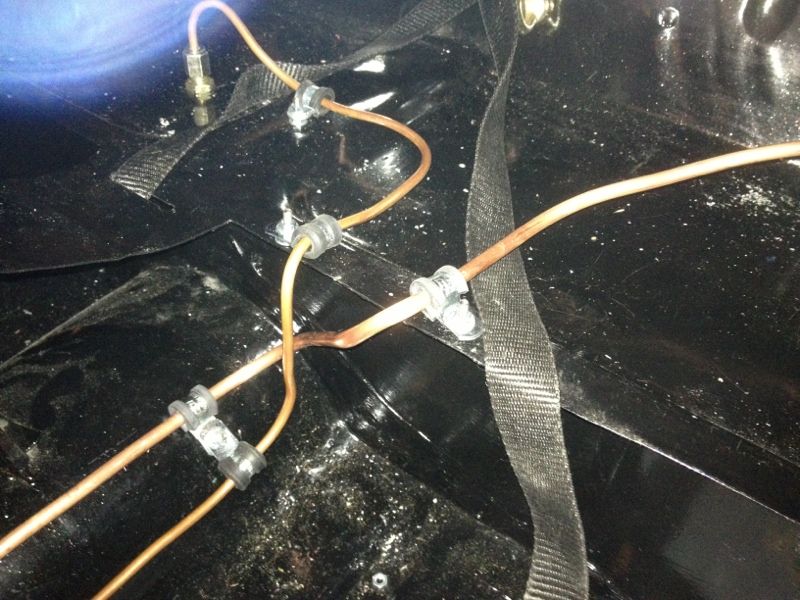

like it - where did you get the rubber strap?

Posted 08 January 2013 - 09:23 PM

Posted 08 January 2013 - 09:36 PM

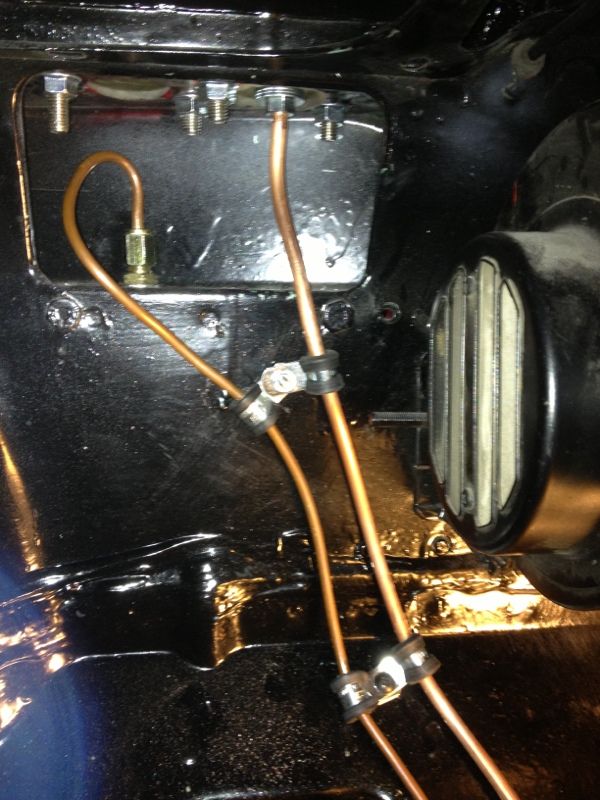

Part of the stage rally regulations are that there has to be a fuel sampling device in the fuel line so here it is

Posted 08 January 2013 - 10:43 PM

Posted 08 January 2013 - 10:53 PM

0 members, 1 guests, 0 anonymous users