Overall it's tight everywhere but my alternator is technically side mounted I flipped it 180 but I have no inner wings :)

This is probably the best pic to show it's position

Get a build thread up. It's much easier to explain with pictures

Posted 15 March 2013 - 05:13 PM

Posted 29 March 2013 - 11:34 PM

Posted 29 April 2013 - 08:01 PM

Posted 30 April 2013 - 08:14 PM

Posted 03 May 2013 - 04:32 PM

Posted 06 May 2013 - 08:36 PM

Edited by sashafelix, 06 May 2013 - 08:36 PM.

Posted 06 May 2013 - 10:40 PM

Posted 07 May 2013 - 08:24 AM

Is there anything in it or is it just empty?

Some just have a baffle between the inlet and the vent so that oily mist being blown into it can't just head straight for the vent. If there's nothing then you'll probably find that the filter gets very oily very quickly and then the same thing happens.

Some fill them with coarse wire wool which gives the oil something to condense on and it then drains to the bottom it also acts as a baffle. Then you can have a tap to drain it to a suitable container when necessary or run a line for it to self-drain back to the sump.

Iain

Posted 07 May 2013 - 12:02 PM

Posted 07 May 2013 - 04:37 PM

Posted 07 May 2013 - 04:53 PM

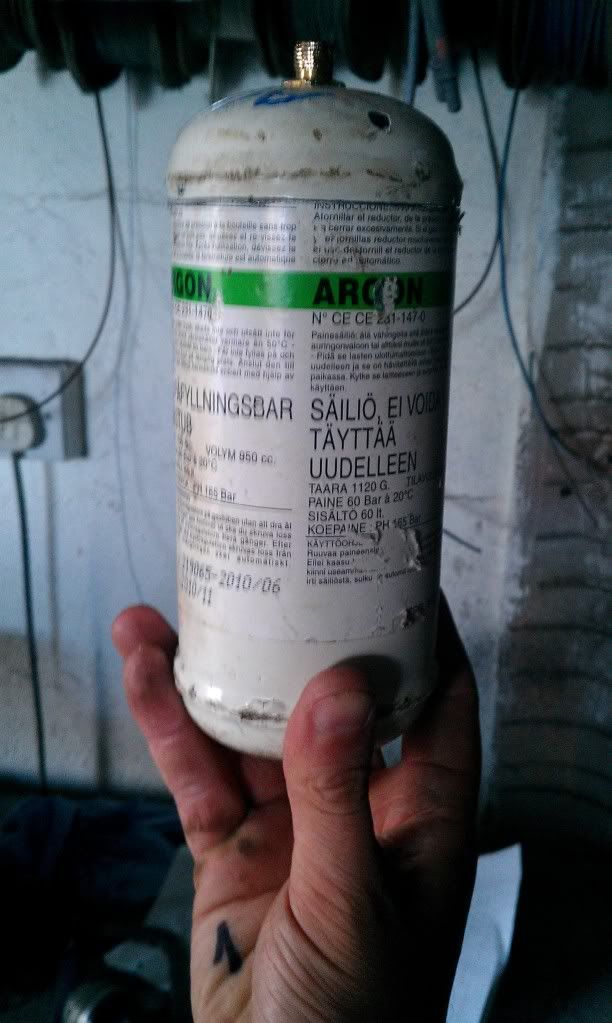

I got loads of these bottles may have to do the same thing nice work!

Posted 08 May 2013 - 09:49 AM

The top is packed with course wire wool, welded some rods across the tank to stop it falling down.

I might steal the idea but with a slight modification - I'd make the inlet like an inverted L so that the vapour entering the tank actually does so right at the bottom. That way it's got to pass through the maximum gauze/whatever before it gets to the filter and once it's been on for some time possible even some liquid. Gives the maximum chance for the liquids to condense out so that all that reached the filter is gas that shouldn't then condense in the engine bay. Plus I'll try to add a tap on the bottom for draining purposes. Sort of like the air filter on my old Land-Rover but in reverse.

I'm still up to my elbows in Micra wiring at the moment. My Micra has NATS and although I know I can get the ECU modified to remove it I'm actually trying to keep it as an immobiliser. The lack of documentation/info available isn't helping but I'm fairly sure I've got it straight now and the version on my S-reg car isn't that complicated.

Iain

Posted 11 May 2013 - 05:48 PM

Just bought some ITB's ![]()

Im in no rush to fit them but it probably will be done by the end of the summer ![]()

Posted 14 May 2013 - 05:34 PM

Posted 16 May 2013 - 01:25 AM

Hi, just bought a 1999 1.3 micra and already have the engine out and all the wiring sorted which i was worried about considering it has NATS.

now, i lowered the engine into my subframe yesterday just to see where to start, and i just can't decide where to cut first!

But anyway, my question is, how accurate do the tie rod mounts have to be? as i think i can build a frame, and your frame is the one i like best,

just im thinking when its all done and it comes to welding the tie rod mounts will they have to be in the perfect place?

Thanks,

Jon

0 members, 1 guests, 0 anonymous users