Well its 07 Sep 14 and I have now started my new Job which includes a spell at Uni so the project has had to be laid up for a while.

In order to get to a natural point to halt proceedings I have had to work like 10 men for the last week and although I did not achieve everything that I wanted to I am happy ish with what I have done.

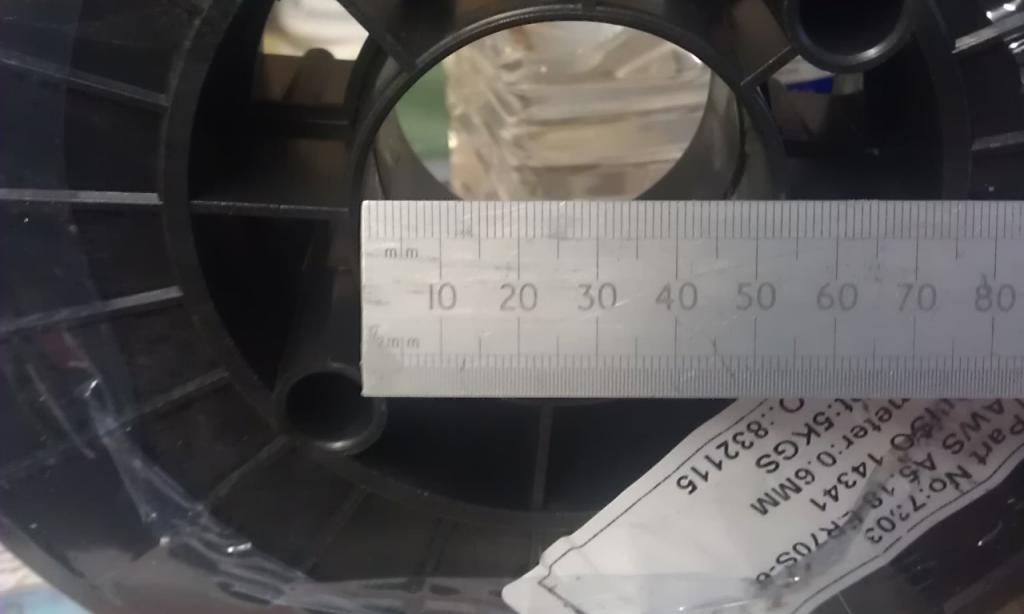

Since the last post I have had two days and late nights hard slog, but working at this rate it is easy to make mistakes and things have been against me. During the last batch of work my welding wire ran out so I had to get some locally, I could get another roll of 0.7Kg Hobby Wire, which is what I have always used, but I thought I'd see if I could use a larger roll, its more expensive but better value for money.

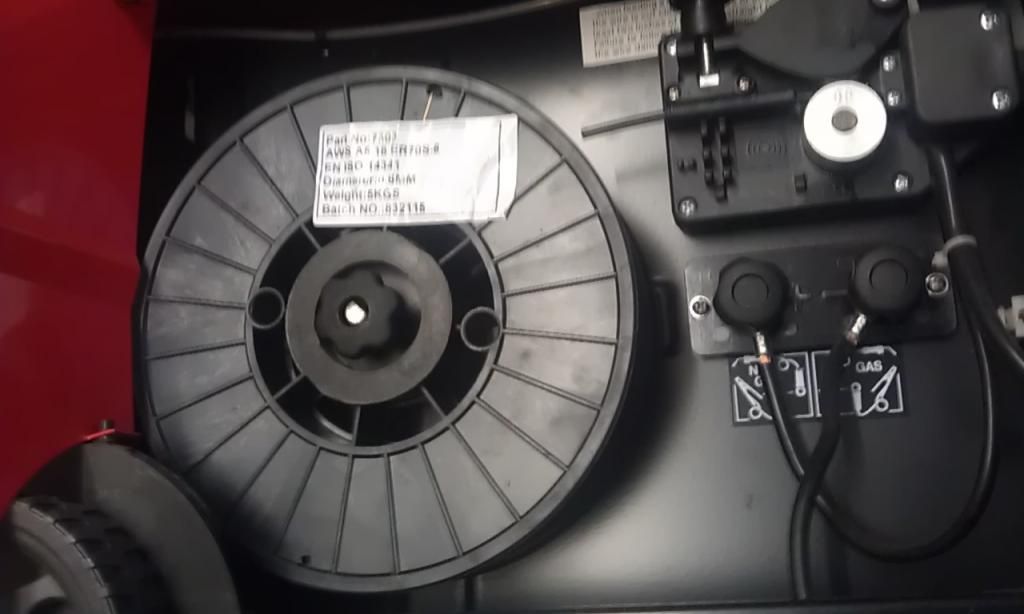

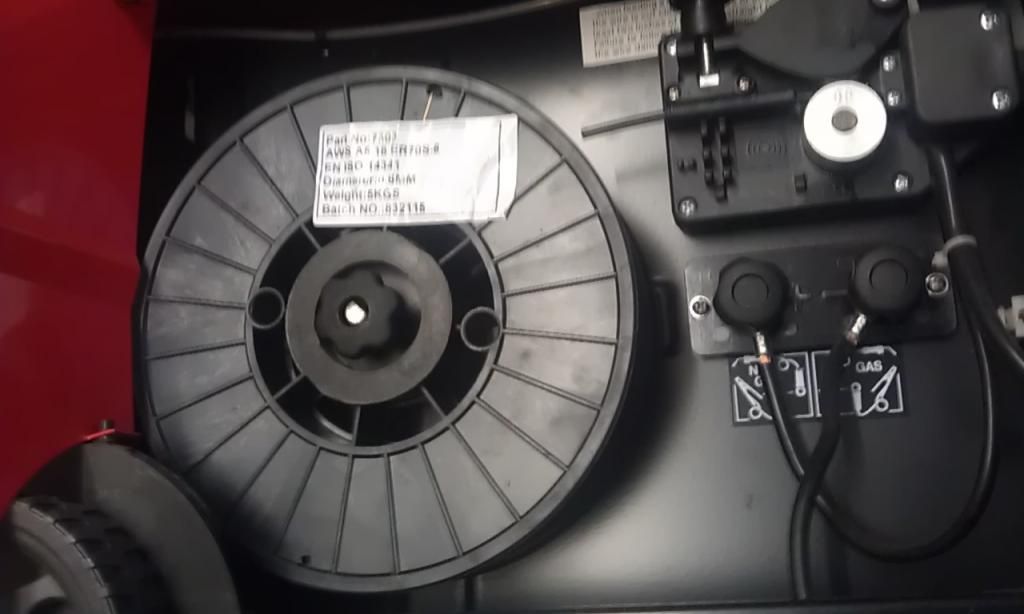

Whilst asking for advice on the Mig Welding Forum on what other brands of welding wire I could use in my Clarke 160EN I was advised of a mod that would allow 5Kg rolls to be used. The mod involved cutting an empty 0.7Kg roll in half and using it as a guid for the larger roll.

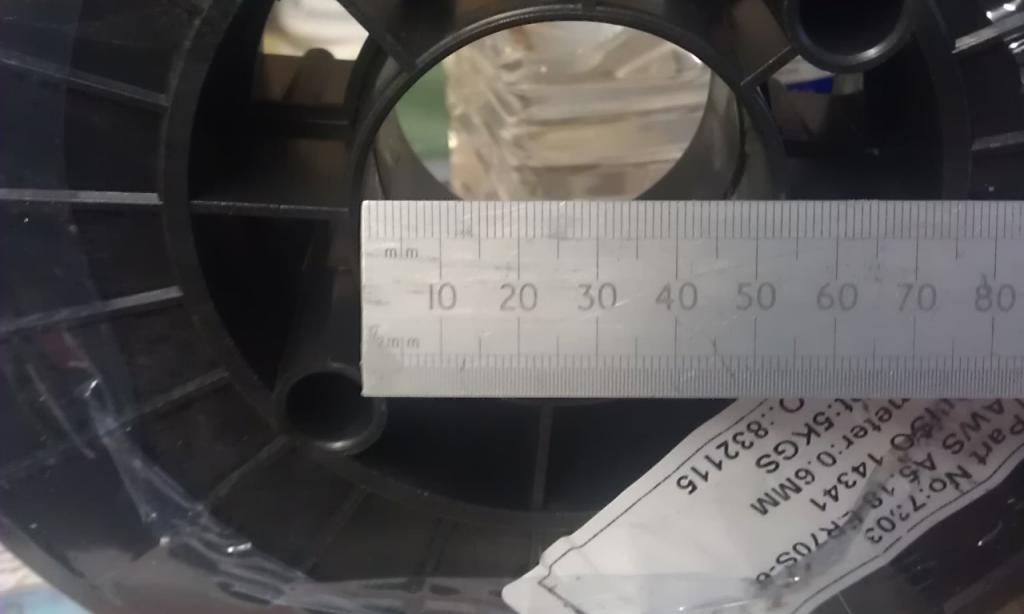

The Clarke Hobby Welders take a roll with a centre spool diameter of 15-16mm but the larger rolls have a 50mm hub diameter. As long as the external diameter of the empty roll (where the wire wraps onto) is 50mm you can use an empty roll as an insert.

So armed with a 5Kg roll of Super 6 I set to task:

Here's the internal diameter of the Super 6:

And here's the external diameter of the Clarke 0.7Kg Hobby rolls that I have been using:

Near enough matched so I cut the empty roll in half:

And using the old roll as a guide inserted into the new roll it fitted nicely:

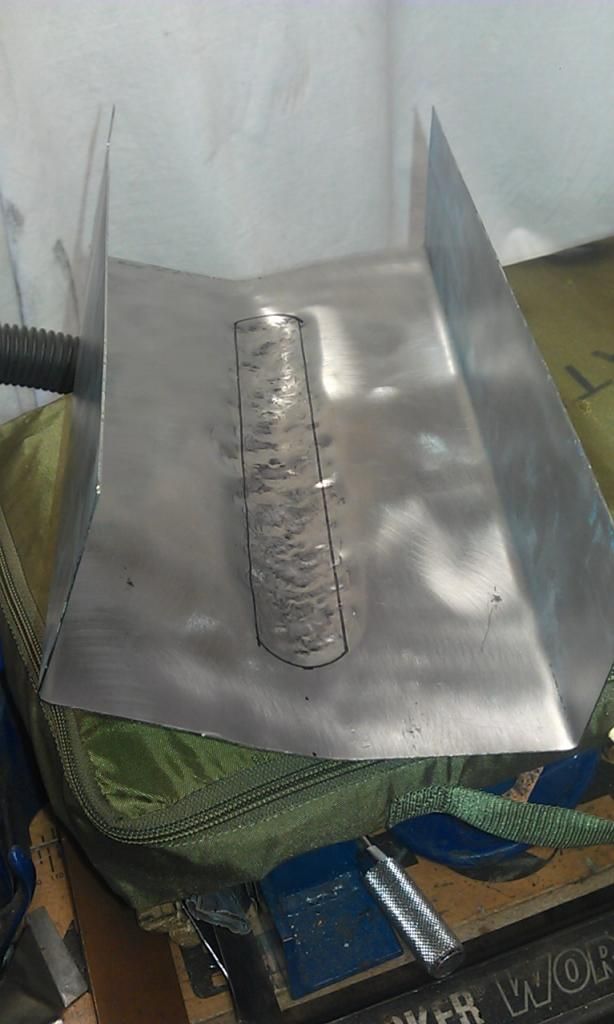

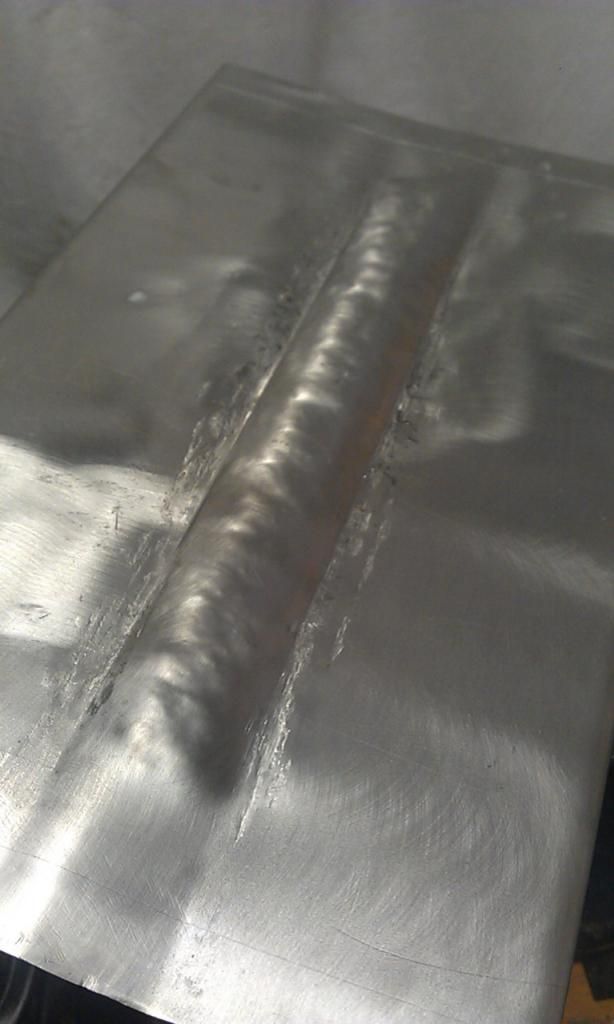

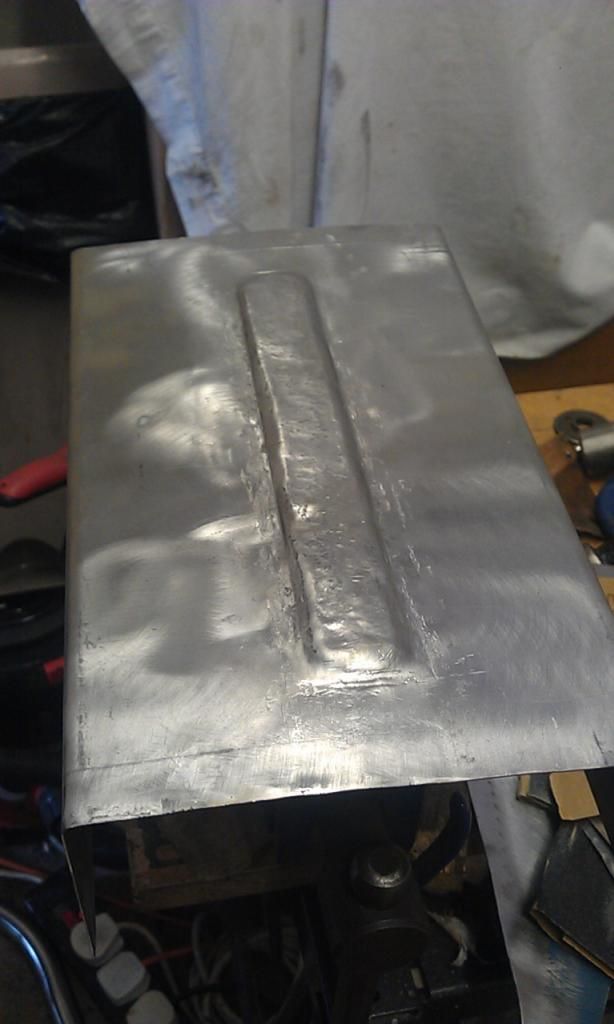

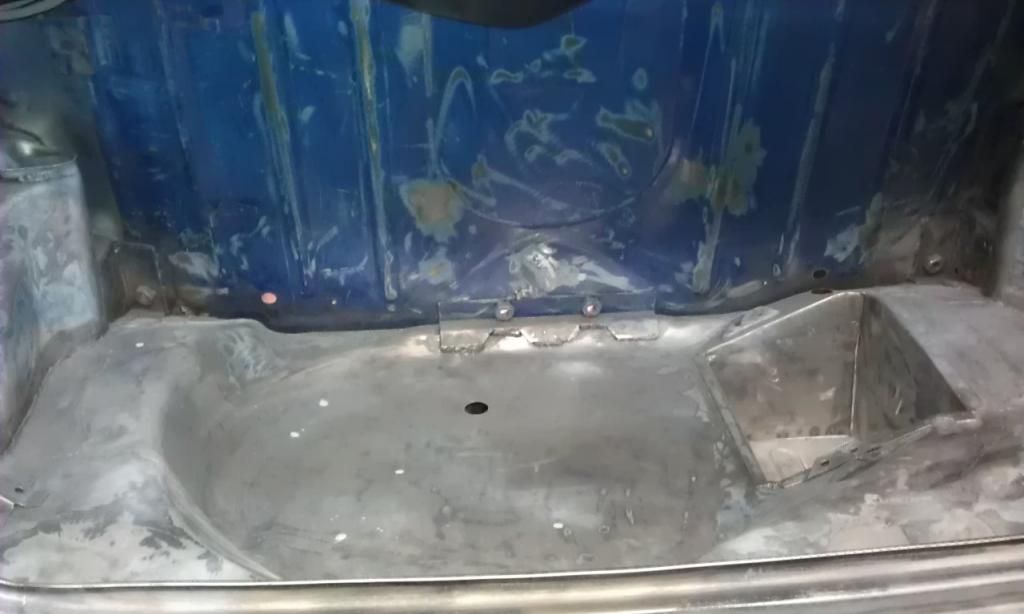

So I welded up the 4 x plug holes in Rear Seat:

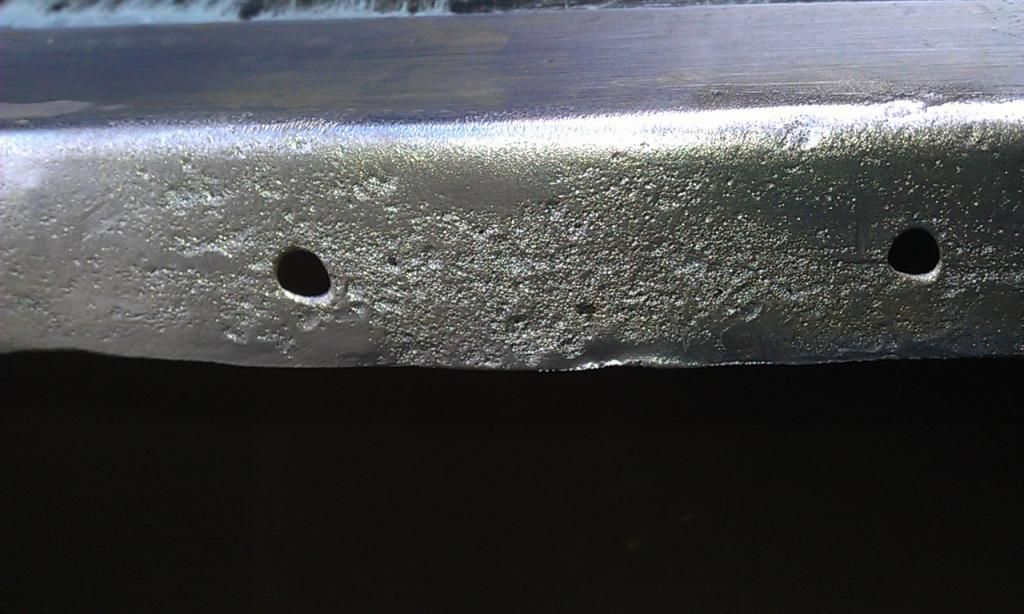

And after some additional cleaning on the underside came across another area that needed a patch, was I ever going to get the underside painted with all these set backs:

In the mean time I recieved a call from the Shot Blaster to say that he could finish my wheels but it would cost more than £50 that he first envisaged :-( it ended up being a little less than his second quote and came in at £64 for 5 wheels. He did a pretty good job but having OCD I spent another hour manually digging out the paint from the internal recess and obtained several blisters in the process!!

One of the wheel had already started to re-rust so time was precious:

Iv'e got 2 different serial numbers of Wellers, what do the numbers dictate YOM?

And the spare is a Manx Weller copy:

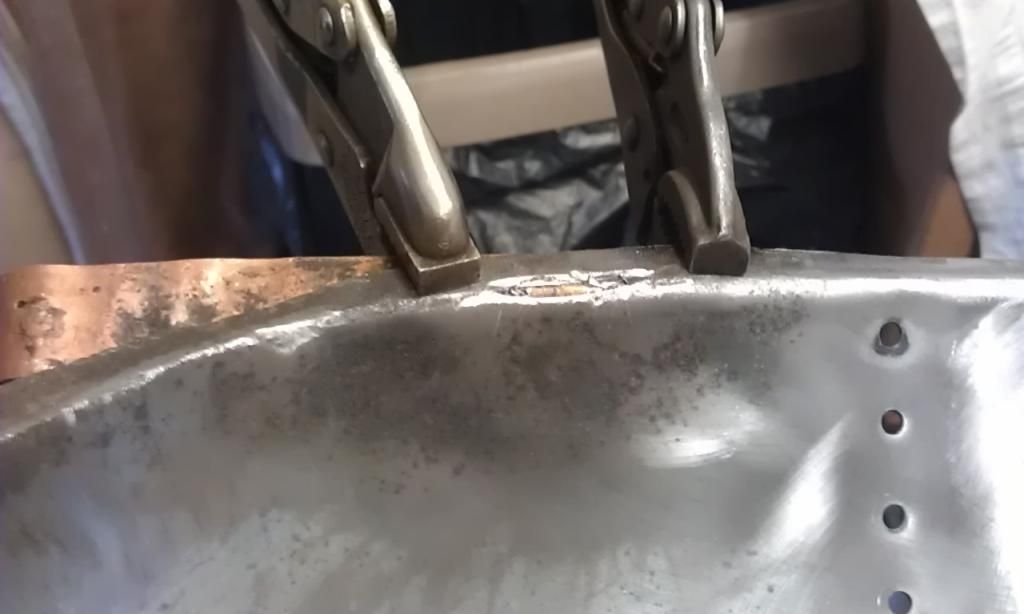

One of the wellers had some bad curbing which I had already planned to repair, the basic idea was to build up the dents and rust damaged areas with weld and sand down using a Flap Disc, I also used copper to prevent overweld to minimise what needed to be ground down:

This part of one of the rims had a lot of minors dents but after some welding and gentle grinding:

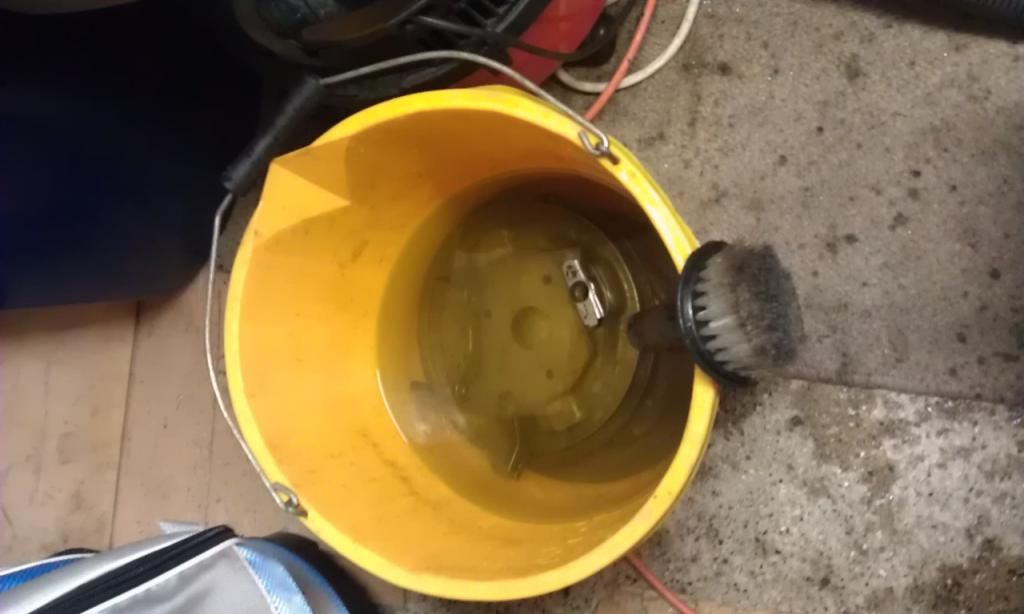

Also after several spells in the Citric Acid Bath here are the Backplates:

Next after cleaning up the paint from inside the wheel rims I noticed some rust that needed a bit of treatment, I thought I remove it by a gentle soak in citric Acid, big mistake I ended up causing some major surface rusting that now needed to be manually cleaned, this took me another hour, a delay that I could have done without, still it was a nasty lesson learned!!!

After cleaning up AGAIN I was scratching my head trying to work out how to mount the wheels after I had given them their first coat of Epoxy. I couldn't lay them on the floor as they would have been painted so came up with the idea of mounting them through their centres on pieces of wood held across the steps of a ladder:

I also primed the Rear Hubs and Handbrake Cable Brackets:

During the same late night session I applied the last layer of Primer to the Rear Subframe, after cleaning up the Spray Equipment I finally sacked it at 02:00!!!

In the morning I got some better photo's of the temporary spray shop and the wheels having had a second coat of Epoxy, this time sprayed on.

The following day and nights progress involved giving the Wheels, Subframe, Hubs, Backplates and Brackets two coats of Fast Engine Enamel:

Here are the wheels, at this distance they look the Dog's:

When you spray at night however you are bound to miss a few bits so these will need a touch up, as will a couple of the wheels:

You can just see the primer on the inside radius:

And a couple of drips:

The Subframe has a few imperfections but apart from that it's SWEET AS!! Do you like the OEW?

Only missed parts of the insides of the Rear Rubber Support Cups:

So the rest of the morning involved cleaning up the garage and packing away the good work to avoid it getting trashed:

My old faithful safety boots had to go, (not safe anymore as the soles have disintegrated):

And so the project is packed up ready for an intermission, who knows when I will managed to get stuck in again, I may manage the odd day here and there but I anticipate another 2 - 4 weeks solid work will be required, :-(

Until next time................