Another full day today but very little visible progress sadly as I spent most of the day making up a panel for the Rear Seat / Boot Floor.

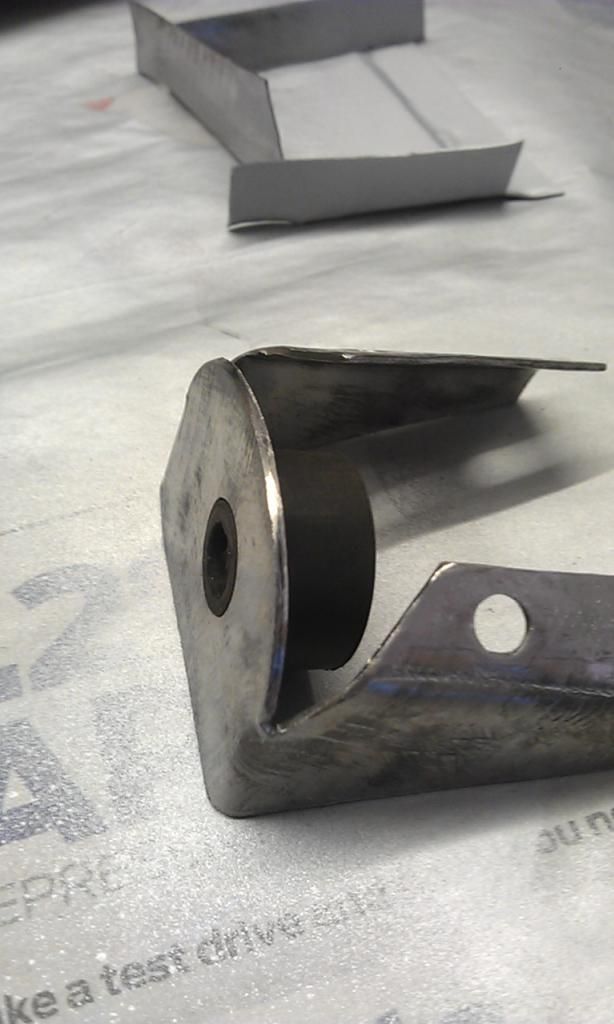

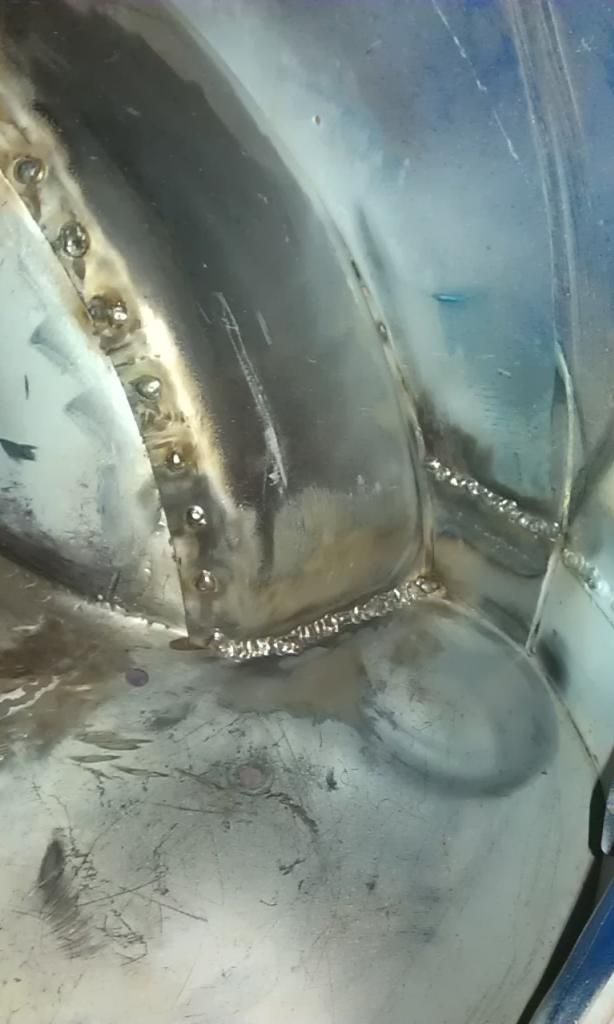

Before I could make this panel however, I had to clean up and weld the rear of the Companion Bin to the Rear Arch.

Here it is all cleaned up ready to weld:

Got it welded in but no photo.

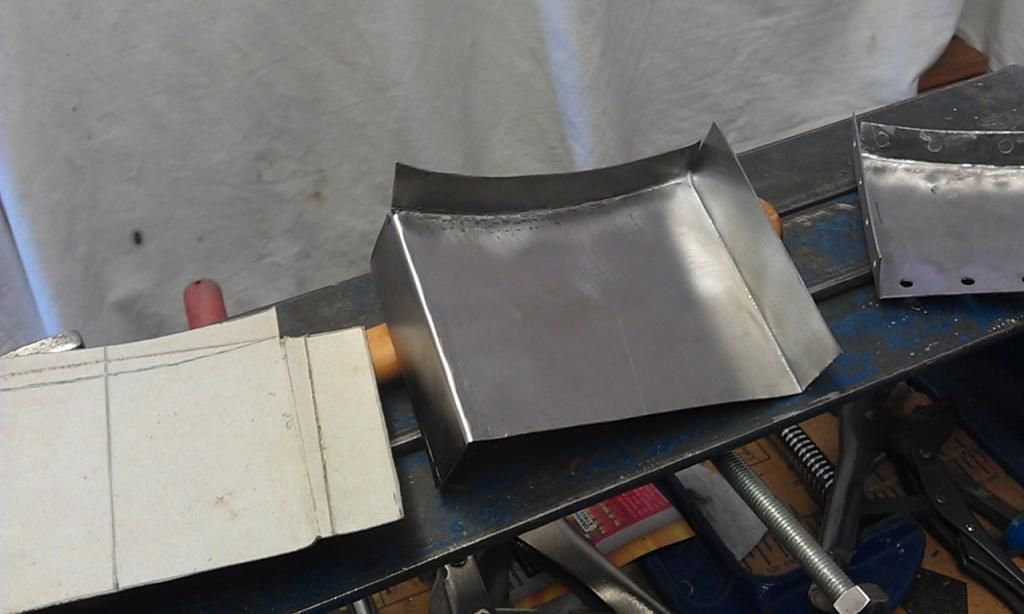

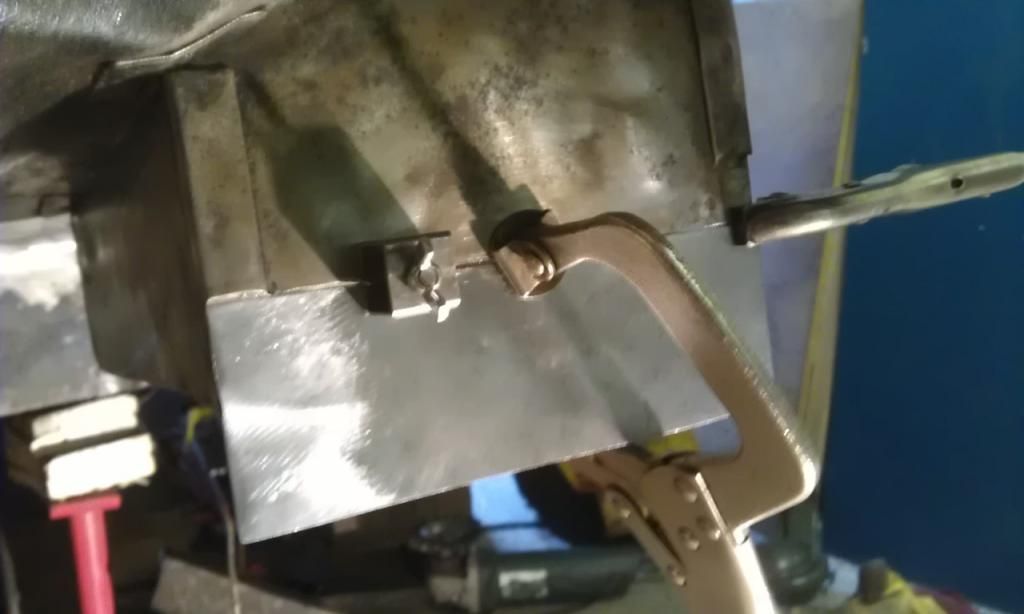

Next I made a cardboard template for the patch and spent most of the late morning / mid afternoon knocking this up and getting it to fit nice and snug. If it doesn't fit its no point welding it:

I then marked up where to drill the spot weld holes and then punched and drilled them, just need to spray the mating areas with Weld Through Primer.

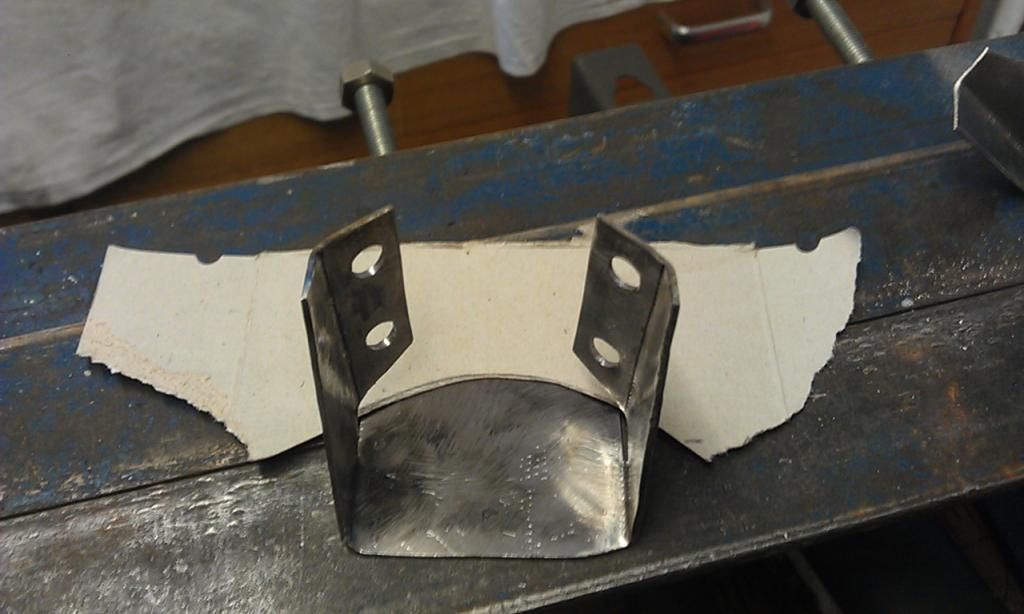

While I was test fitting it I noticed that I needed to repair the bottom rear edge of the Companion Bin, the piece between the Rear Seat and Subframe Close Out Panel, the bottom had rotted away and was removed when I cut out the Seat and Heelboard.

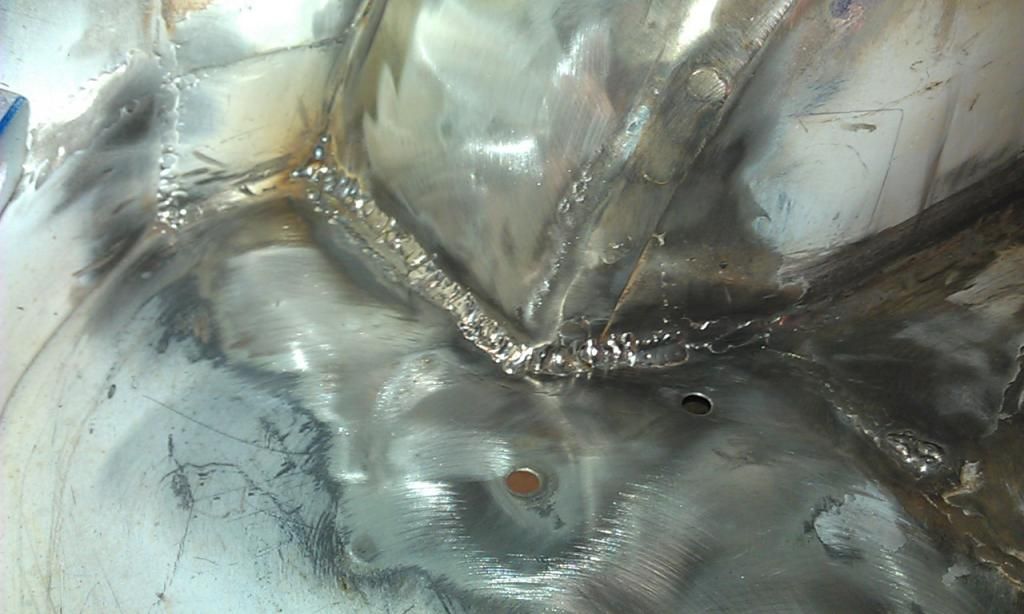

Just as I thought I was ready to weld everything up I realised that I had not cleaned up inside the Rear Seat to Wheel Arch Bracket, it contained a lot of surface rust. It was a real pain to clean up as it is such a small area but I got there in the end.

After I cleaned it I needed to go over the underside of the Boot Floor where I would be welding with a Fleece Disc to remove any surface rust.

I set the Angle Grinder to permanent on and set about the task, just before I finished I caught an edge and the grinder flew out of my hand and as it was still on it flew off across the garage, I chased after it and managed to grab hold of the flex and hauled it back and switched it off.

It was like a scene from Tom and Jerry, luckily no damage was done to me or the garage but the Fleece Disc was split in half, sadly these are about £7 a shot and I now need to buy another :-(

After this episode and while I was waiting for the Primer to dry for a change I decided to have a go at cleaning up the Rear Valance as I would soon be in a position to weld it back on.

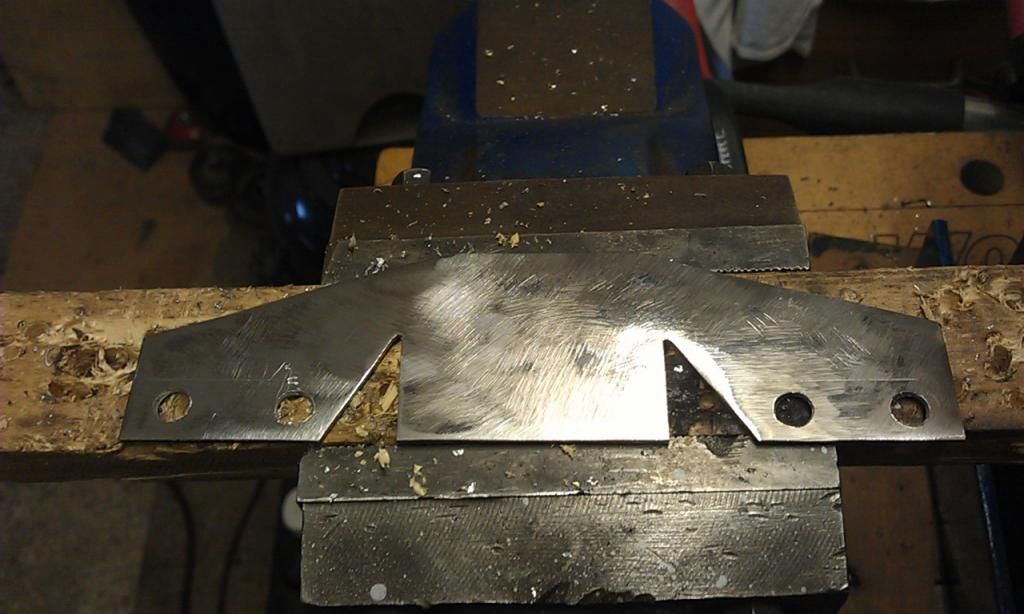

It was in a right state with half the back end of the Boot Floor still attached to it, as well as someones attempt at a home made Closing Panel:

Managed to get all the excess metal off and the Rear Valance is salvageable thankfully, just needs a clean up with a Flap Disc to remove the last of the welds and a Twisted Knot and finish off with a Fleece Disc, when I get a new one ![]()

Oh and the Postman delivered another package - the Chrome Wheel Nuts and Alloy Centre Caps for my 5 x 10 Wellers (Not refurbished yet!!!)