Bit more progress today,first of all I decided to finish striping the Radius Arms in order to paint them properly.

I took off the caps using a screwdriver, starting with a thin blade and then a large screwdriver, they are just pushed on but can be quite tight. SO you have to push, or tap, the screwdriver in and twist it to lift the cap. Work around a little at a time.

Once the cap is off straighten and pull out the split pin holding on the castle nut and then undo the nut with a socket. I worked out that one side is a Right Hand (undo) thread due to the wheel revolution direction.

Once the nut was off the hole bearing section and wheel hub came off nice and easy - phew.

To remove the backplate undo the three 1/2 Inch bolts, the backplate and rear cable support will separate from the radius arm.

Next I removed the Knuckle Nylon Cups, one was stuck in solid the other came out relatively easily. To remove them I used a screwdriver to push down on the cup taking care not to touch the metal inside. I then used a pair of pliers to lever them out.

My knuckle sockets are in good order (thankfully).

Here they are separated and ready for wire brushing:

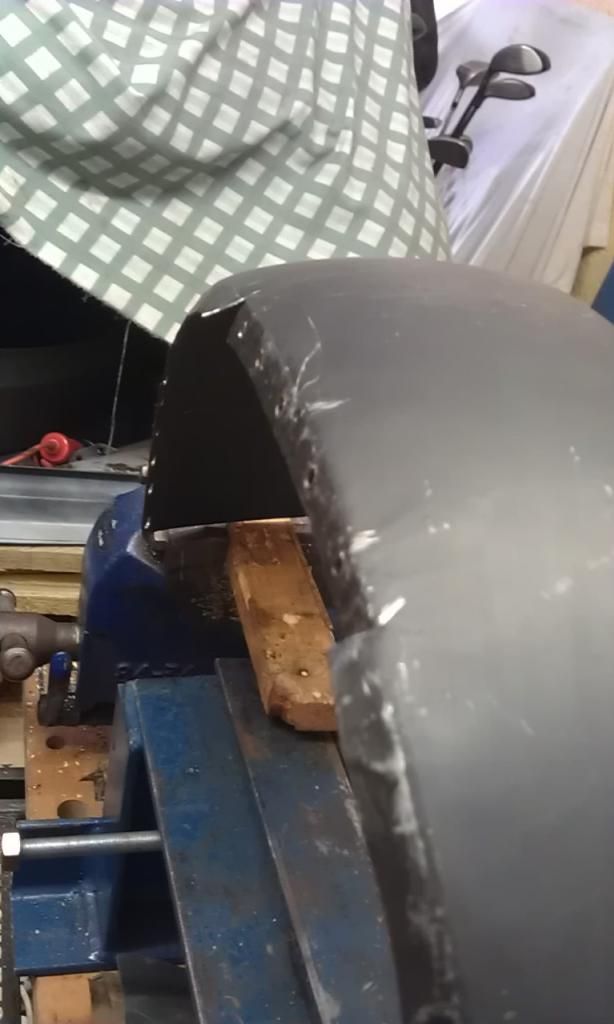

One of my backplates had a rusted through in two locations so I cleaned out the hole to good metal and made a small patch to weld in:

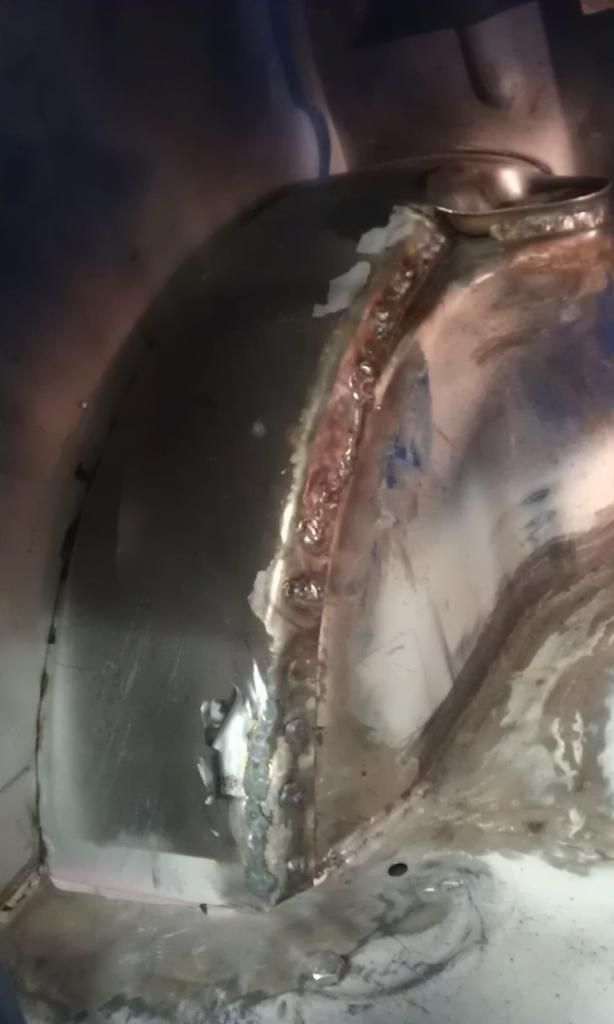

Here are the holes after welding and dressing - good as new:

Now what to do about this bit:

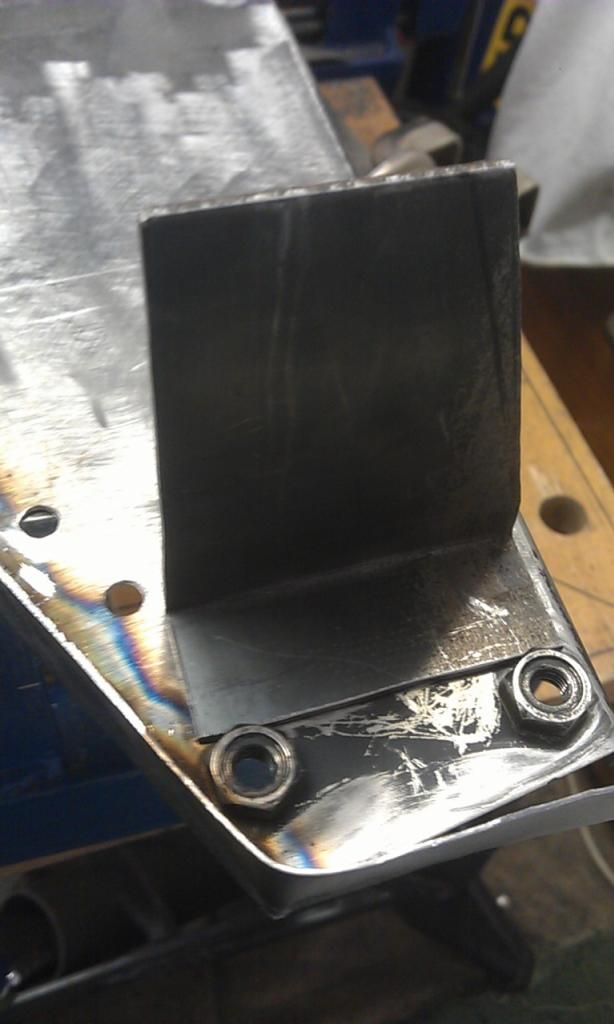

Then lunch break and off to the Post Office to pick up a missed parcel, my adjustable Camber Brackets for my rear Subframe arrived, bought off of this forum:

They'll look 'sweet as' on my newly refurbished Subby ![]()

Just waiting for the Brake Pipes etc.