OK made a little progress today, first off I managed to get the Toe Board Repair Piece that I made welded in place. Here it is clamped in:

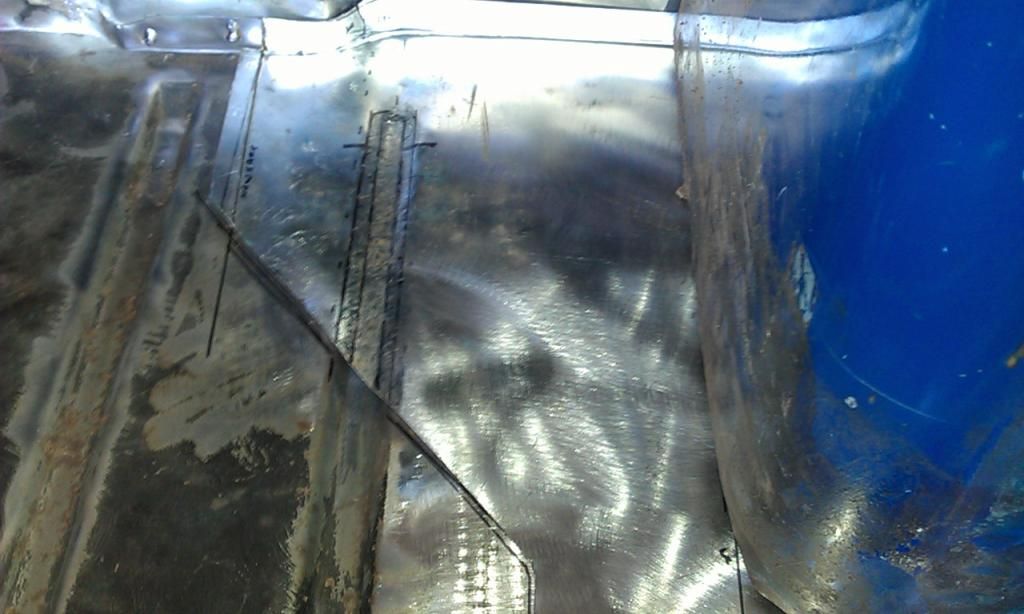

And here it is welded in and dressed down:

And a close up:

Wasn't going to dress it down that far as it will be under the carpet but hey ho did it carefully and no thinning, will look great painted.

Oh another close up:

The welded round spots to the right are where I went a bit over zealous drilling out spot welds, didn't notice at first but when I was checking the Toe Board weld for holes with a torch i noticed it shining through a couple of these so I plugged them with weld and ground them down.

Next I went to tackle the front edge of the LH Cross Member, it has rusted and has been badly repaired in the past (a lot of that on this car).

First I had to get rid of the rotted Jacking Point without removing the door step, I know this seems a bit of an odd way of doing things but I have no choice as I can't afford to cut the hole thing to bits and don't have the space :-(

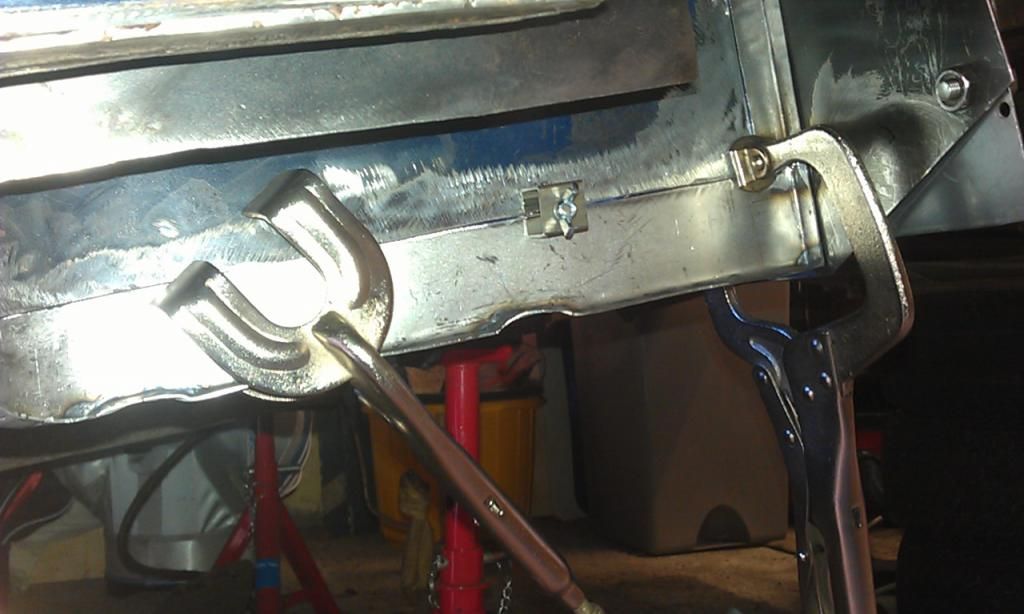

Here's the culprit:

And here is the Cross Member with the bad area removed:

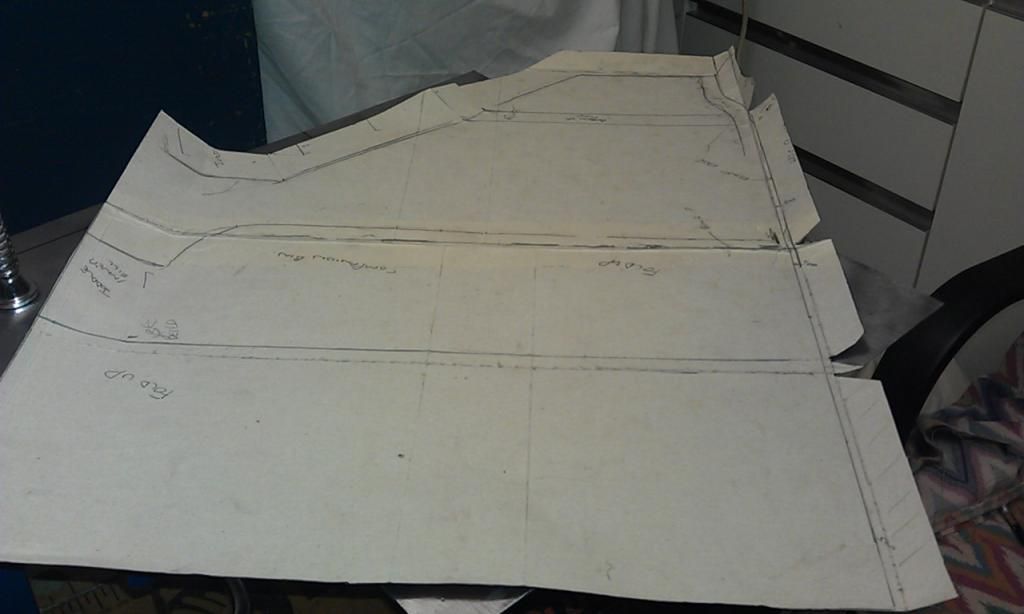

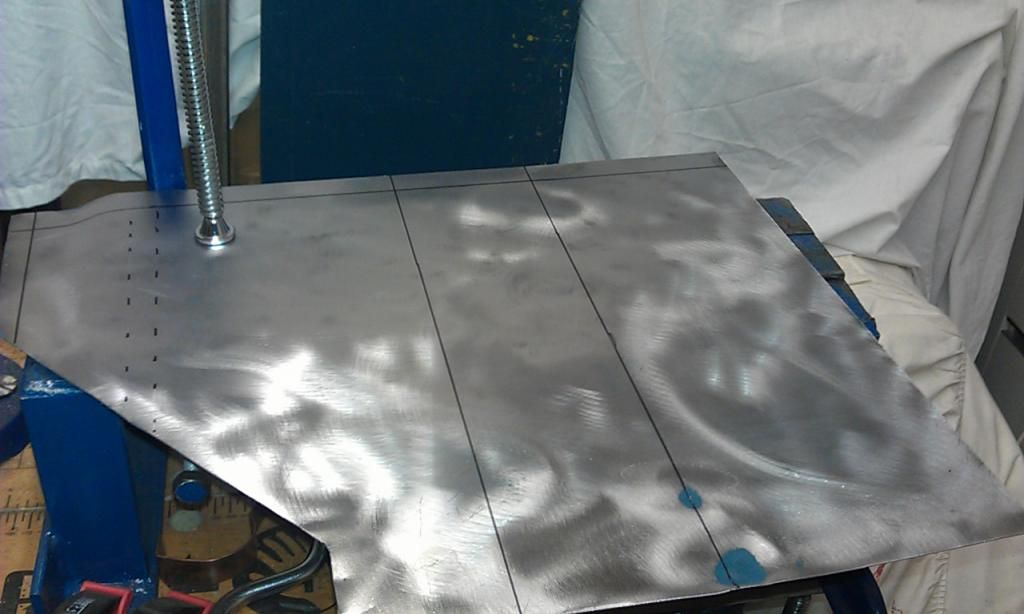

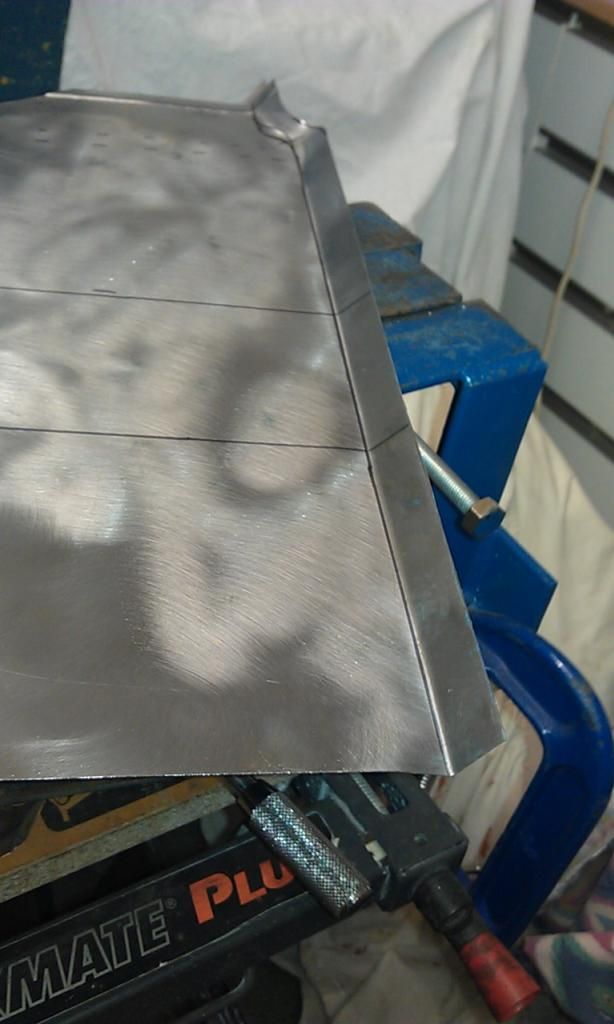

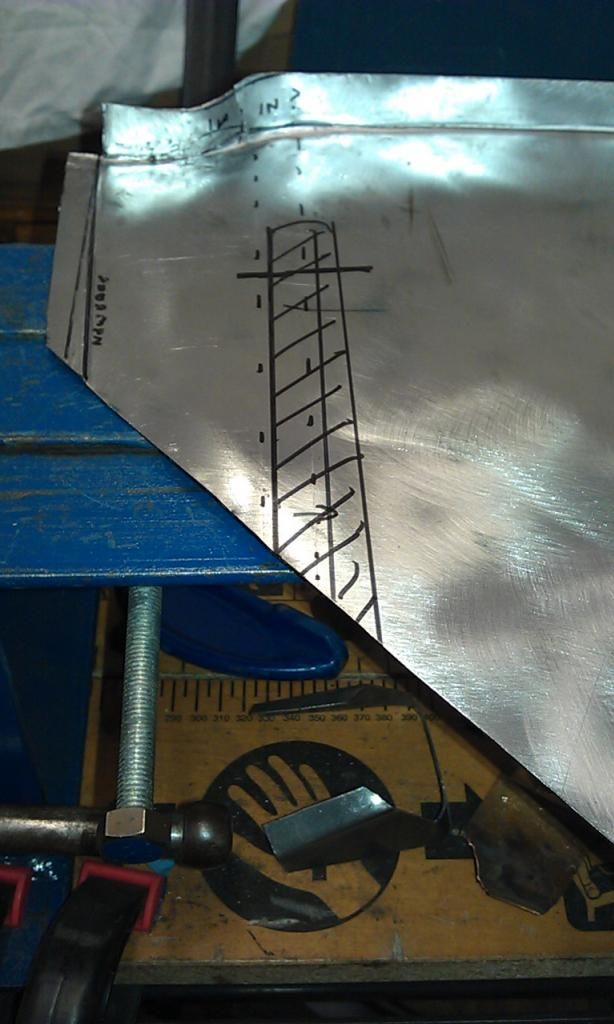

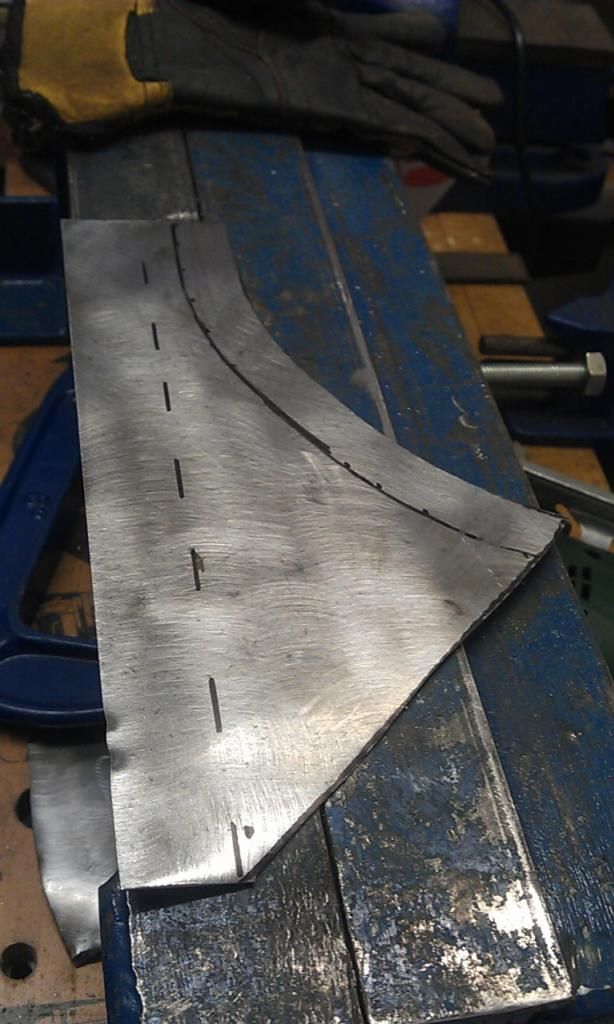

As if by magic - Ta Da:

Made a cardboard template marked up some 1.2mm sheet metal, cut it out with a Jigsaw, folded it in my Home Made Bender, test fit, few adjustments after measuring it against the good side and along the remnants of the Inner Sill. Welded it and dress down the weld penetration. I welded it from the inside and will leave the welds as they are for strength.

And here is another view of it with the internal area cleaned up a tad:

Can't get in too far and its pretty gungy and orange on the floor so I leant in with a hand driven wire brush and hoover and will splash in some rust converter.

In the pic above on the left you can see the remnants of the Inner Sill and part of an Inner Sill Repair Panel that a previous owner had welded in over the top of the old Inner Sill added to this was the oversills and all the rotten bits where just left sandwiched in between!!!

At the rear end ,Companion Bin area, I kept the top edge of the original Inner Sill and Butt Welded to it, but behind the Cross Member the Inner Sill repair and the Original Inner Sill will both be removed and replaced. However the piece of the Inner Sill that sits between the Cross Member and the Door Step is rusted and will be a problem, the Jacking Point also needs replacing and this cannot be done until I get the old one completely out. You cannot see it in this pic but the top flange of the Jacking Point is still in place.`

The problem I have is my current bracing is two pieces of Angle Iron going from the A Post and B Post to the Inner Sill above the Cross Member and I daren't remove them until I have at least the Front Floor In.

My plan (at the moment) is to Complete the Front Floor to give back some strength and poss also do the floor from the rear under the Cross Member and the cut a section out of the middle of the Door Step to complete the Inner Sill Repair and re-fit the Jacking Point.

Or do the Front Floor and fit a new Brace on top of the Cross Member welded to the A Post and B Post but leaving enough room to work on the Inner Sill?

Edited by JonnyAlpha, 19 June 2014 - 07:30 PM.