Managed to get out into the garage just after lunch just around the time Mr DHL delivered my latest package

That'll be my new Scuttle panel and a few other bits (Goodridge Front Brake Hose, Braided Petrol Pipe, clips etc).

Did some more work on tidying up the wings, they are going to take a lot longer that I first anticipated

Also not sure whether to weld up the spot weld holes that are too close to the edges and re drill them?

Whilst I was waiting for some Deox to work its magic on the wings I made a start on the Scuttle. First job was to measure the window height (as suggetsed by Sonnik4 in another thread on Scuttle Panel option. 41 - 41.5cm. Next job was to centre punch the spot welds and drill a mm or so into the spot weld with a 5mm drill, this will help the Spot Weld Drill Bit:

Then drill out the Spot Welds and split the seam with a Wall Paper Scraper ( I have had this old scraper for years and today it finally broke, one too many tough welds!!).

You'll notice I hadn't removed the Windscreen Wiper mounts yet

In a couple of areas I had to use a 1mm Angle Grinder blade with not to much damage, I'll nip that up with a bit of weld.

The Scuttle cam off pretty quick (always quicker dismantling things than putting them back together!!).

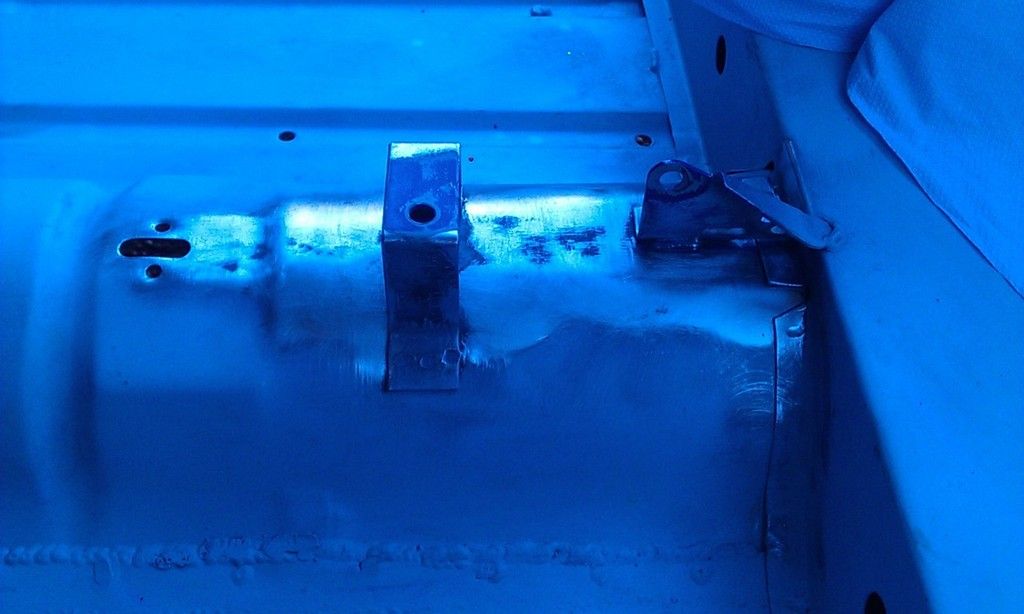

Apart from the corners, which have already been removed, the underside was in pretty good condition.

I was pretty good with the Spot Weld Drill, only left a few marks, not sure whether to weld these up or not? I cleaned and sprayed the area with weld through primer anyway.

When test fitting the new Scuttle, I noticed that my Inner Wing repairs were maybe too high and the flange was in the way, so a quick cut was needed.

Glad I went for a Heritage, the profile is soooo much better.

There is also a lot more post on the fill panel so I trimmed a bit more off of the Mini.

I noticed however that the scuttle still wasn't sitting right and decided it was my inner wing repairs so I adjusted them downwards with a little persuasion.

I test fitted the Scuttle Closing Panels, the profile against the Scuttle is perfect but they are not sitting particularly flush with the Inner Wing. I marked them and tomorrow will remove the Scuttle and make some adjustments before I weld them in.